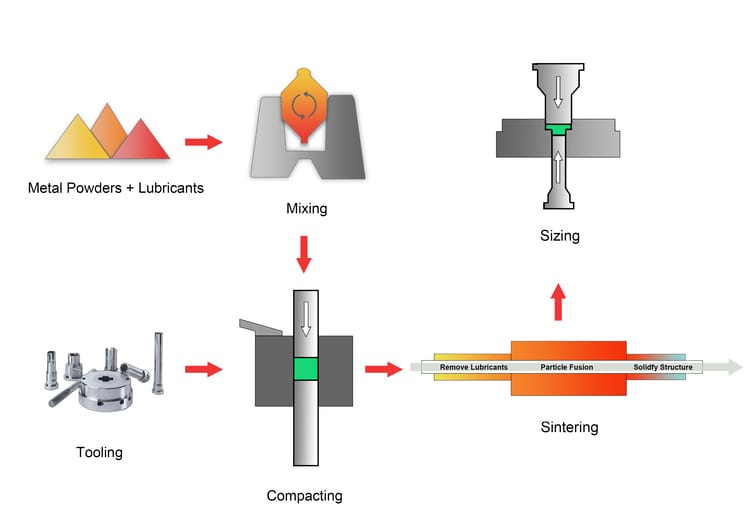

Powder metallurgy process is recognized as a green manufacturing method that uses metal powder as raw material to form green parts through high-pressure die compaction, followed by sintering to fuse the powder particles together. It is an excellent method for producing structural parts at fast speeds and with tight tolerances.

Contents

Steps of Powder Metallurgy Process

The powder metallurgy process mainly includes powder production, mixing, compaction, and sintering.

Powder Production

Powder production is the first step in PM. It’s no exaggeration to say that the characteristics of the powders determine the quality of the final components. Among the various powder production methods, the most commonly used are atomization process, reduction, and chemical decomposition.

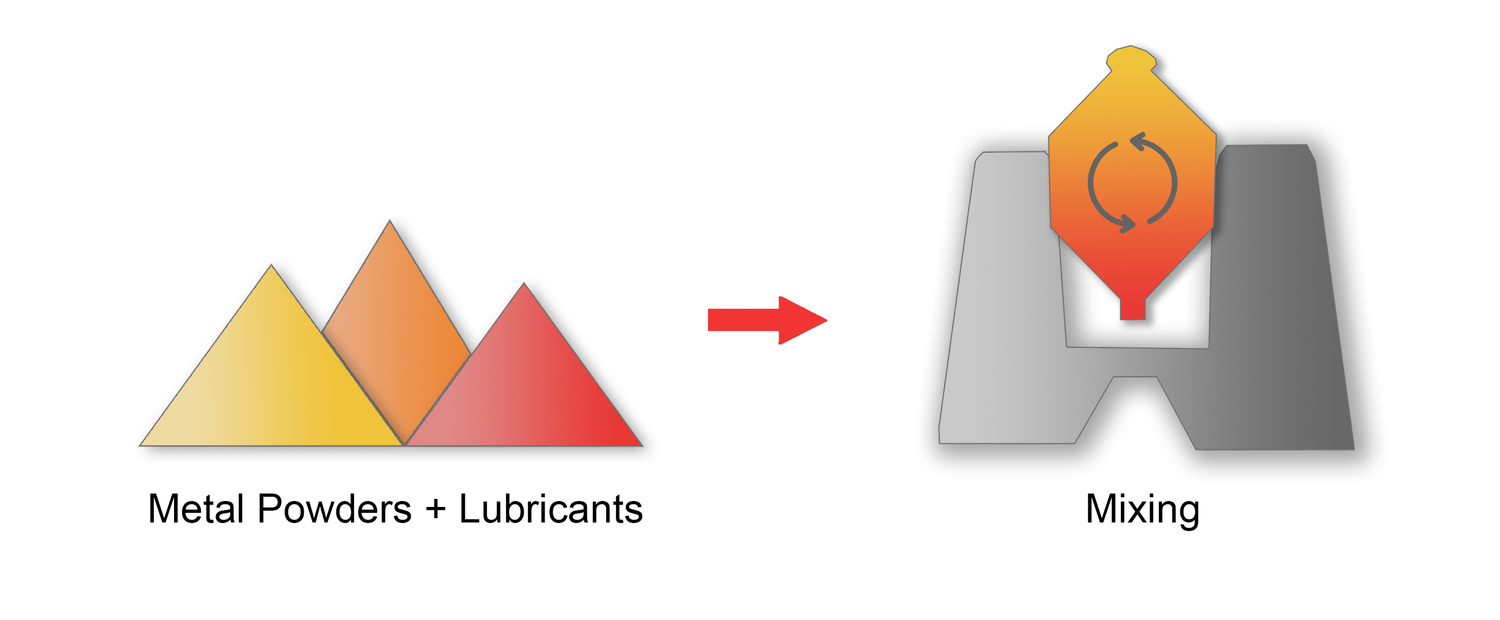

Blending and Mixing

Blending and mixing refers to mixing metal powder with lubricants or other alloying elements to produce a uniform mixture.

Powders include mixed powders and pre-alloyed powders.

Pre-alloyed powders are produced by adding alloy components to molten metal when reproducing powder particles. The pros of pre-alloyed powders are their uniform microstructure and mechanical properties, but the cons are that they have increased hardness and poor compressibility.

Mixed powder generally refers to a mixture of iron powder, copper powder, carbon powder and a binder. The disadvantage is that it is difficult to mix evenly, but the advantage is that it is easy to produce dense workpieces. The effects of adding lubricants are as follows:

- Improve the fluidity of the powder. This helps to shorten the time to fill the mold cavity and make the green density more uniform.

- Increase the loose density and compressibility of the powder.

- It helps to reduce the friction between the powder and the mold and reduce mold loss.

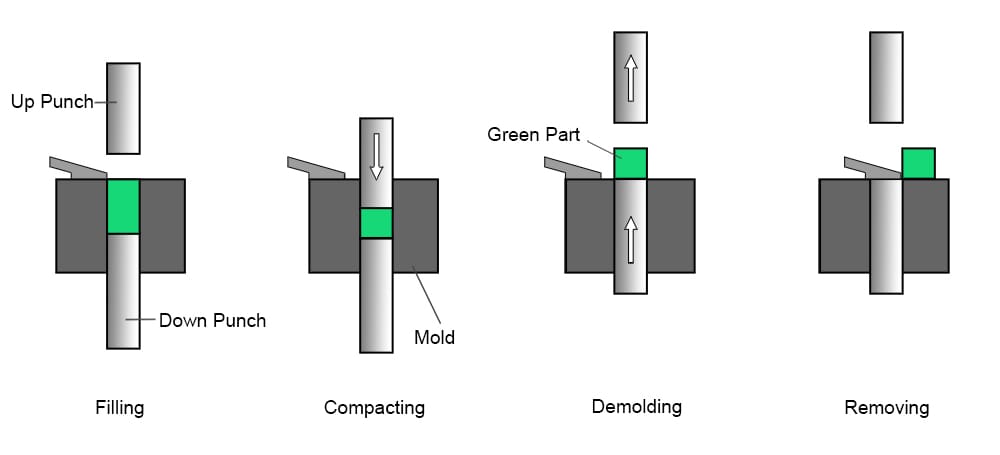

Compacting

Powder compaction is a forming process where metal powder is filled into a mold cavity with a powder box, and then pressed into shape by the powder metallurgy press. The resulting product is called “green compact‘’.

There are several main compaction methods:

Single action compaction: In this process, the upper punch applies pressure and the lower punch and die do not move. This method easily results in a product with high density at the top and low density at the bottom. Do it is only suitable for thinner components. This press is cheap.

Double action compaction: During the forming process, the top punch and the bottom punch compress the powder at the same time. This results in a uniform green density

Floating die: In this method, the upper punches press down, the lower punch does not move, and the die drops to half of the upper punch stroke.

The first two methods utilize a demolding technique where a downward punch ejects the workpiece. In the latter method, the die continues to descend, exposing the workpiece at the top of the die.

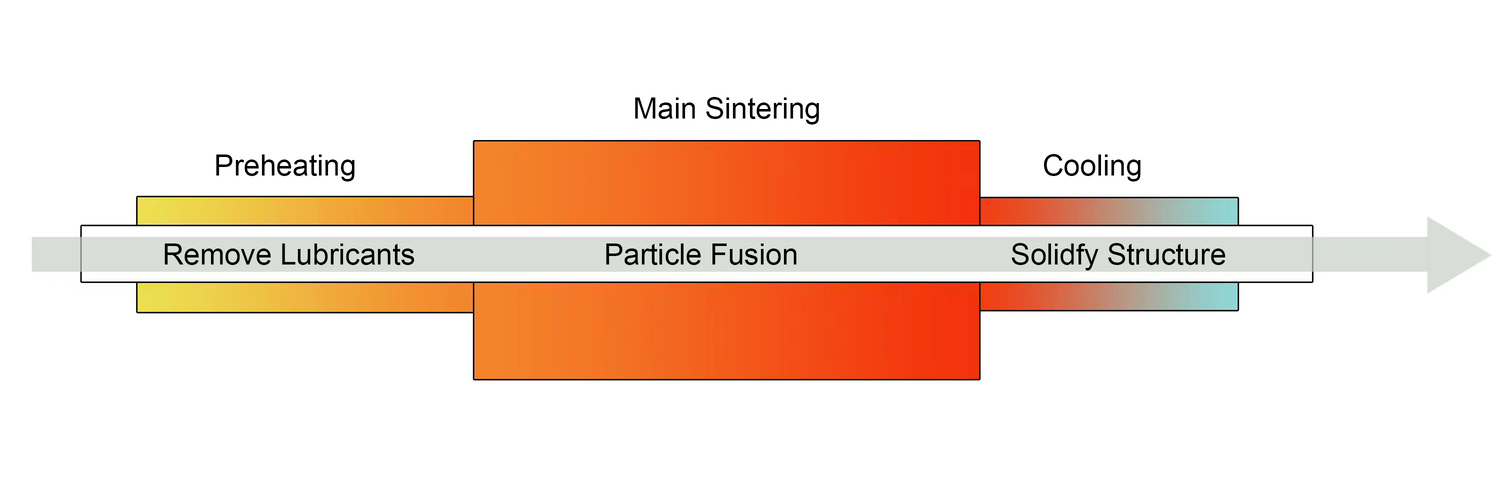

Sintering

Green compact is as strong as chalk, so you need sintering process to improve its mechanical strength.

Pre-sintering

The lubricants and binders mentioned earlier assist in powder flow and forming. However, they must be removed before the high-temperature sintering process, as they hinder bonding and densification between the powders. Typically, pre-sintering is conducted at 500 to 900 degrees Celsius for 30 to 45 minutes, during which these lubricants and binders evaporate into gas. It’s important to heat gradually, as heating too quickly might cause defects such as bubbles, bursts, or cracks.

Sintering

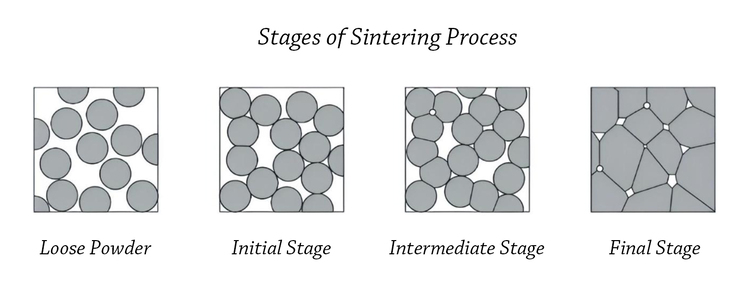

Sintering diffuses and bonds metal particles at temperatures below their melting point, usually between 80% and 90% of the melting point. It includes 3 stages.

Initial Stage (Neck Formation)

When the green compact is heated to the sintering temperature, atoms begin to diffuse at the contact points between the particles, forming surface contacts (also known as necks).

Intermediate Stage (Densification)

As the sintering time increases, diffuse becomes more pronounced. The atoms diffuse through the volume and crystals. The necks become larger, and the distance between atoms decreases. As a result, the product becomes less porous and denser. This stage is significant to enhance the mechanical strength of the finished product.

Final Stage (Pore Closure and Gain Growth)

In the final stage of sintering, interconnected pores become isolated pores. Gas is trapped inside the pores but could be slowly expelled. Due to the resistance of compressed gas, it is difficult to density. It also leads to rapid growth of gain structure. At this stage, you must balance the densification and gain growth to avoid compromising the mechanical properties of the sintered parts.

The shrinkage of the components during the initial and final stages of sintering is minimal, typically around 2% to 3%. The majority of sintering phenomena, including significant densification and bonding, occur during the intermediate stage.

Cooling

Cooling is the gradual reduction of the workpiece from the high sintering temperature to room temperature, which takes about 2 hours.

Cooling not only helps to eliminate thermal stresses but also prevents defects caused by cooling too quickly.

Temperature and Atmosphere

The main functions of the sintering atmosphere are as follows:

- Prevent outside air from entering the sintering furnace and causing product oxidation

- Help burn off lubricants and binders in the workpiece

- Reducing the oxide layer on the surface of the product

- Controlling the carbon content of the product

- Sintering atmosphere affects the mechanical strength, appearance, and production cost of the product.

Common sintering atmospheres include:

- Hydrogen

- Decomposed ammonia

- Vacuum

- Nitrogen

- Argon

The following sintering temperatures of commonly used metals in practice are based on our manufacturing experience.

| Materials | Temperature (℃) |

|---|---|

| Iron-based | 1120 |

| Copper-based | 820 |

| Stainless steel | 1250 |

| Iron-copper based | 1120 |

Secondary Operations

Secondary operations are additional processes performed on powder metal parts after the main steps of the powder metallurgy process. It can improve the dimensional accuracy and surface finish.

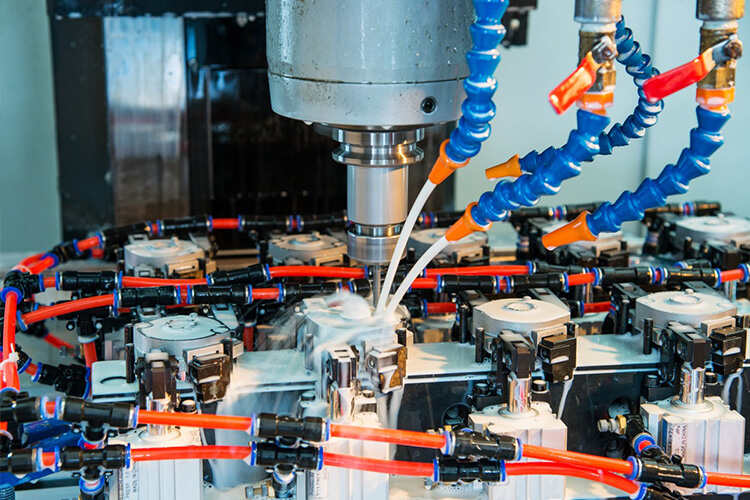

CNC Machining

While powder metallurgy can produce complex shapes, it is extremely challenging to manufacture parts with transverse holes, blind holes, or threads. In addition, PM parts often require machining to improve surface roughness and dimensional accuracy. Common machining processes for powder metallurgy parts include turning, drilling, milling, grinding, tapping, and threading.

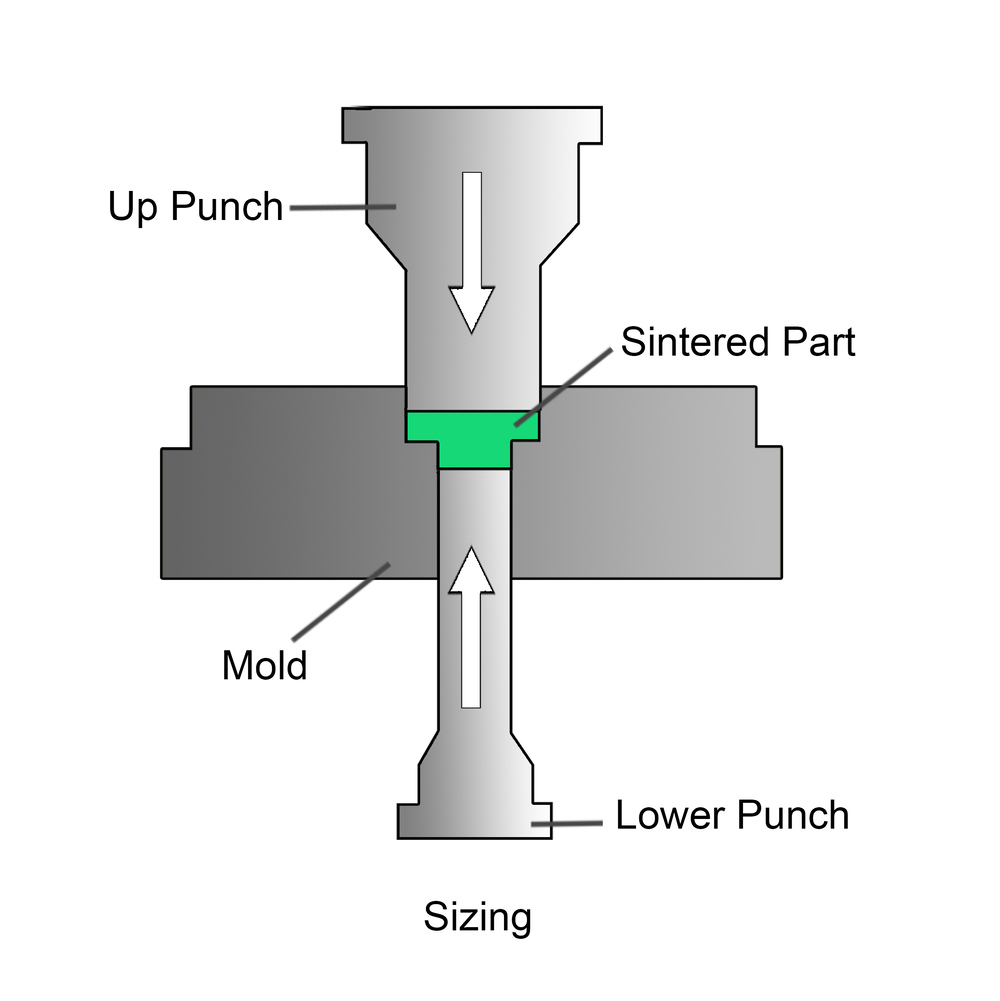

Sizing

Sizing restores the inner diameter, outer diameter, flatness, and other dimensions of sintered part to the correct size. During sizing, the sintered parts are placed in a die, and pressure is applied to correct any dimensional deviations that occur during sintering, such as shrinkage or warping.

For example, in a product with a diameter of 25 mm, sizing enables improve the tolerance from IT8-IT9 to IT6-IT7. Sizing helps maintain strict dimensional tolerances and enhances the surface finish of the product. Besides, sizing can seal the surface pores of oil-impregnated bearings.

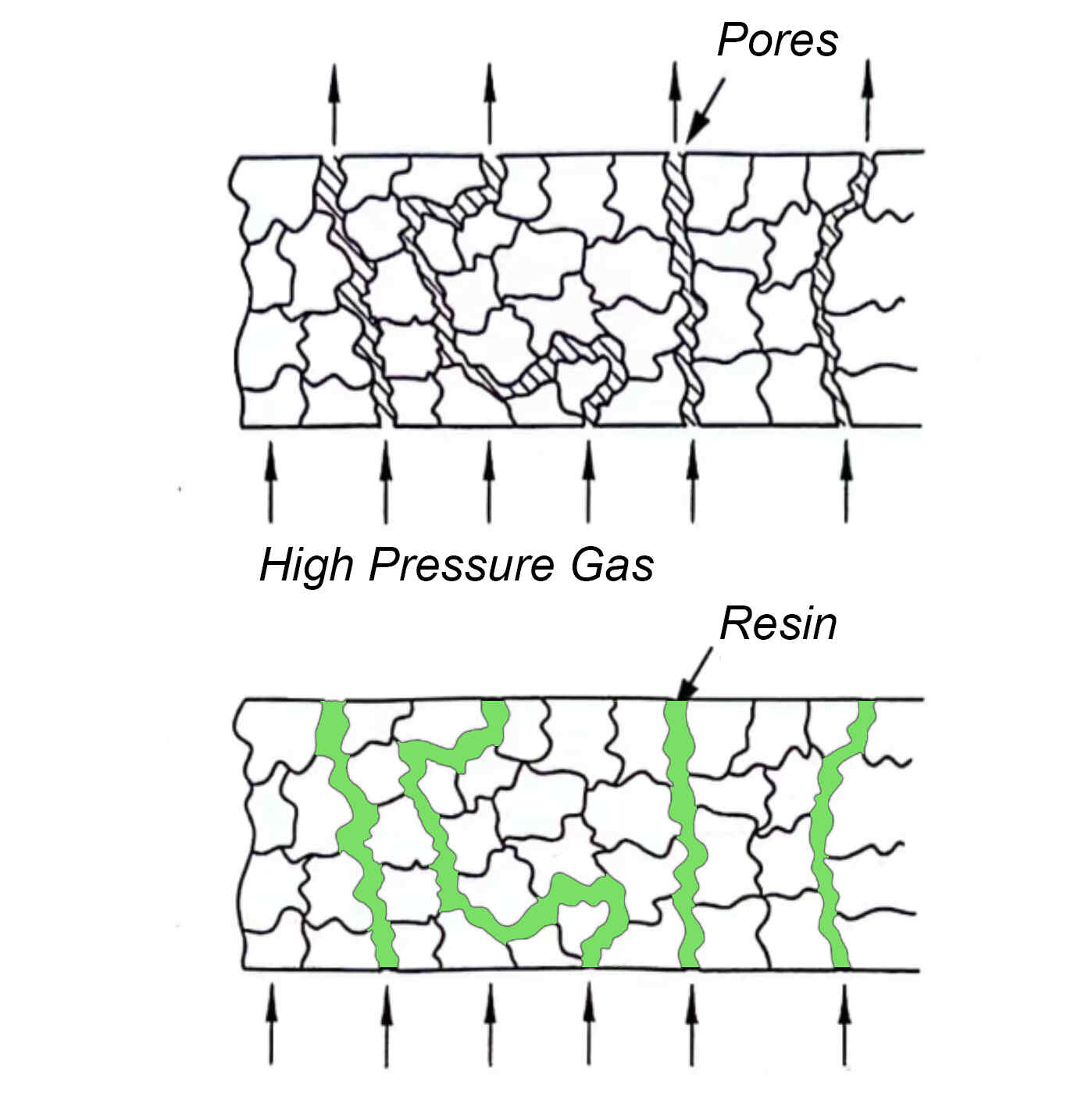

Resin Impregnation

PM products contain many pores, which is not ideal for high-pressure environments. Although copper infiltration could fill these pores, it is more expensive. Resin impregnation is a more cost-effective alternative. Typically, resin is impregnated into the pores of parts using high pressure or vacuum.

Oil Impregnation

When a bearing is in operation, lubricating oil is usually added to reduce friction. Yet, for some bearings that are difficult to access, it is inconvenient to add lubricating oil. This is where oil-impregnated bearings are needed. The oil impregnation process is similar to resin impregnation, so I won’t go into details here.

Copper Infiltration

Copper infiltration is a process used to enhance the mechanical properties of sintered structural parts, typically iron-based. During this process, copper is melted and drawn into the pores of the porous metal parts by capillary action, improving strength and density.

Copper infiltration improves the density, strength, hardness and wear resistance of sintered components.

Tumbling & Sandblasting

During compacting, due to the gaps between the upper punch, lower punch, core rod, and die, burrs are easily formed after powder filling.

You can employ tumbling and sandblasting to remove these burrs. Tumbling knocks the workpiece against the ceramic grinding piece, and the friction by a vibration grinding machine. This reduces burrs and improve surface finish.

Sandblasting is the process of impacting the surface of a product with an abrasive media such as sand, aluminum oxide, or silicon carbide. This process is carried out in a closed environment. Sometimes, sandblasting is performed first, followed by tumbling, to achieve a burr-free surface finish.

Electroplating

Electroplating is a surface finish process that uses an electric current to deposit a thin metal layer from an electrolyte onto a sintered component. This process enhances the surface properties of PM components, boosting corrosion resistance, wear resistance, and electrical conductivity.

Powder Metallurgy Materials

Iron Powder

Iron powderhas good strength and magnetism and is inexpensive. Most structural parts are made from iron-based materials.

Stainless Steels Powder

Stainless steel has excellent corrosion resistance due to its chromium content of more than 10%. It also offers reliable strength, hardness, and magnetic properties. Common stainless steels include the 300 series, 400 series, and 17-4PH.

Copper Powder

Copper, including bronze and brass, has favorable electrical and thermal conductivity, making it ideal for electronic components. Copper is suitable as a substrate for self-lubricating bearings and can also improve the density and strength of iron-based parts through the copper infiltration process.

Aluminum Alloys Powder

Aluminum alloys are suitable for making lightweight structural parts.

Titanium Alloys Powder

Titanium alloys, such as Ti-6Al-4V and Ti-6Al-5Nb, offer elevated strength, excellent corrosion resistance, and good biocompatibility. They have a range of applications including aerospace, medical, and automotive.

Nickel-Based Superalloys

Nickel-based superalloys, like Inconel® 718, are known for their excellent oxidation resistance, high-temperature strength, corrosion resistance, along with strong creep resistance. They are primarily used in the aerospace, automotive, and chemical industries.

Powder Metallurgy Tooling

Powder metallurgy tooling includes the upper and lower punches, die, and core rod.

Upper Punches and Lower Punches

Punches are responsible for pressing metal powder. The number of punches depends on the shape of the product. Punches are mostly made of tool steel, such as M2 and A2 (AISI standard) or SKD11 (JIS standard).

Die

The die is where the metal powder is formed and needs to withstand the axial pressure and the lateral pressure exerted by the powder. Therefore, the die is mostly made of CPM10V, ASP-60, or C11.

Core Rod

The core rod serves to create the internal features of the product.

Because the core rod is long and easily breaks during demolding, it is made of elevated tensile strength tool steel.

Applications of Powder Metallurgy

Powder metallurgy has a wide range of applications, including automobiles, motorcycles, medical devices, aerospace, filters, and household appliances.

Automotive

Automobile manufacturing is an important market for the powder metallurgy industry. There are more than 1,000 powder metal components in automobiles.

- Engine components:

- Timing gears

- Camshaft sprockets

- Valve guides

- Oil Pump rotors

- Oil Pump gears

- Connecting rods

- Transmission Components:

- Synchronizer Hubs

- Planetary Gear Carriers

- Clutch Plates

- Shift Forks

- ABS Sensor Rings

- Exhaust manifold flanges

Medical Applications

Metal injection molding is a special powder metallurgy process. It has the capability to manufacture products that are small, highly accurate, and biocompatible.

Examples are metallic orthodontic brackets orthopedic implants, medical devices, and surgical tools.

Aerospace

Aerospace engineers favor lightweight, high temperature resistant, and mechanically strong parts. Because it not only ensures the safety of aircraft in harsh working environments but also reduces fuel consumption.

Powder metallurgy is able to manufacture these excellent performance products, such as compressor blades, turbine disks, and combustion chamber liners.

Motorcycles

Although there are not as many powder metal parts on motorcycles as on cars, there are still many, including

- Shock absorber parts

- Bearings

- Camshaft governor

- Sintered brake pads

- Timing pulley

- Motorcycle valve guide

Tools

You also see the PM applications in the tools. Some gears in power tools, bushing can be made by PM.

In addition, diamond tools for grinding, cutting or drilling are often made using PM. Diamond particles are embedded in a metal matrix created by PM.

Sintered Filter

Since powdered metal parts have multiple internal pores, it is an ideal process for manufacturing sintered porous filters. Sintered filters have a wide range of applications, including but not limited to filtering water, filtering oil and gas, reducing noise, and diffusing oxygen.

Advantages and Disadvantages of Powder Metallurgy

When choosing the powder metallurgy industry, you’d better weigh its advantages and disadvantages, such as cost, tolerance, and production capacity.

Advantages

- Near Net Shape

Powder metallurgy process is a near net shape process, which means it has high material utilization and less secondary processing.

- Materials

Some high melting point metals and hard metals are difficult to machine, but PM overcomes this challenge. A wide range of materials, including ferrous and non-ferrous metals, are suitable for powder metallurgy

- Complex Shapes

Powder metallurgy is capable of manufacturing components with complex shapes, such as thin walls, varying step heights, along with angled features. These characteristics are difficult to achieve with forging and stamping.

- Tight Tolerance

PM could achieve strict dimensional tolerances. Usually within ±0.05mm is acceptable.

- Mass Production

The powder metallurgy process, including pressing and sintering, can be highly automated, allowing for the rapid production of large quantities with minimal human intervention. Continuous sintering furnaces, like conveyor belt furnaces, are built for non-stop operation, boosting output and efficiency.

- Batch Consistency

The variations between batches of powdered metal parts are minimal. Consistency between batches is important for the stable and reliable operation of the products.

- Green Manufacturing

Powder metallurgy process is recognized as a green manufacturing process for the following:

Powder metallurgy generates very little waste and typically uses less energy than processes like casting or forging due to lower processing temperatures and fewer steps.

Additionally, PM produces less harmful wastewater and gases compared to traditional manufacturing process, like casting and machining.

Disadvantages

- Size& Shape

A powder metallurgy manufacturer typically produces components with relatively limited diameters, commonly in the range of 5–300 mm, due to constraints imposed by powder compaction press capacity.

- Density

Powder metallurgy is not capable of manufacturing full dense products, and the density usually does not exceed 95%.

- Tooling& Equipment

As we all know, powder metallurgy molds are very precise, and materials like tungsten carbide used in these molds are quite expensive, leading to substantial mold costs. Furthermore, the powder metallurgy process demands more equipment, which increases the initial investment.

- Surface Finish

Unlike other workpieces, powder metal parts have many pores inside. So the pores need to be filled before the electroplating process. This will increase production costs.

The scale of the Chinese PM market grew from US$1.9 billion in 2017 to US$2.35 billion in 2021. Chinese powder metallurgy technology is well-developed, and its products are consistently high in quality. These products have been serving the European and American automotive industries for many years. Moreover, the pricing is highly competitive.

BLUE is an ISO 9001:2015 certified manufacturer in China, providing a full range of powder metal parts. We supply standard components with no tooling fees, including structural parts, sintered bushings, MIM parts, and sintered ceramic parts.

You’re welcome to explore our SHOP to compare and select available parts. If your specifications are not listed, we also provide custom powder metallurgy services tailored to your needs.

Contact us today to get started with standard or custom PM parts!

FAQ

Can you Explain the Benefits of Powder Metallurgy over other Metal Forming Methods?

Compared to traditional metal manufacturing processes such as casting and machining, powder metallurgy offers several distinct advantages:

High Material Utilization:

Compared to casting or machining, which often result in significant material waste, powder metallurgy processes offer a high material utilization rate exceeding 95%.

Near-Net Shape:

Powder metallurgy processes produce near-net shapes, with parts produced in a single press. This not only reduces subsequent secondary processing but also shortens production time.

Economical and Efficient Mass Production:

Powder metallurgy production lines are highly automated, with powder presses capable of producing 20-30 parts per minute. Because powder metallurgy produces minimal material waste, PM offers significant price advantages for high-volume production.

Flexible Design:

Powder metallurgy uses metal powder as raw material, allowing engineers to add alloying elements based on product characteristics.

Sustainability:

PM is recognized as a green manufacturing process due to its high material utilization and low energy consumption.