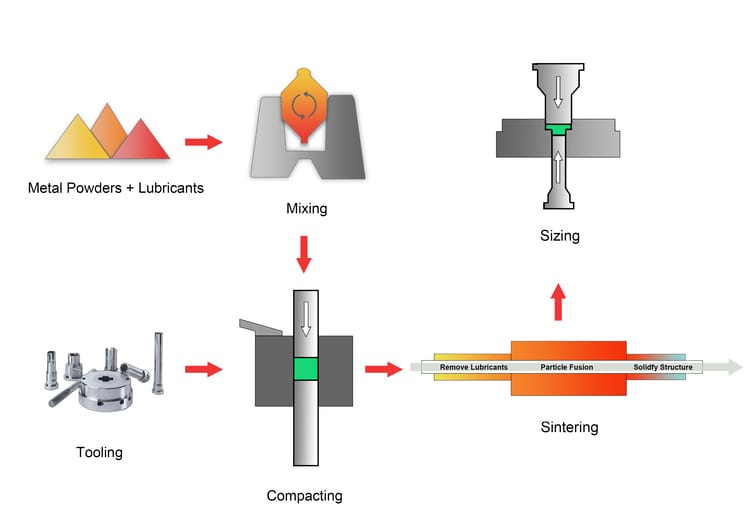

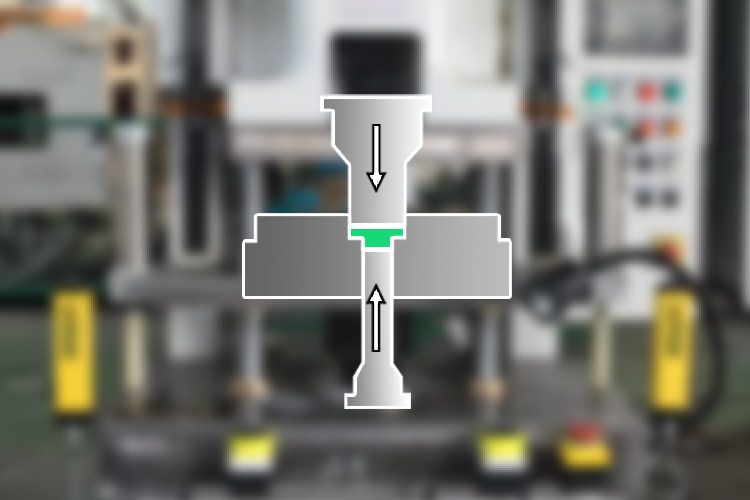

What are the Advantages and Disadvantages of Powder Metallurgy?

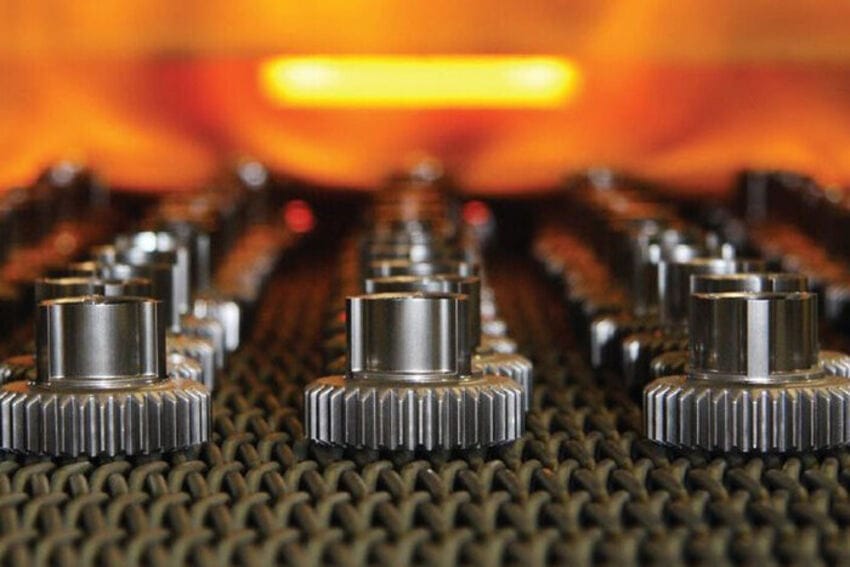

Powder metallurgy is recognized as a green manufacturing process with numerous advantages.

It offers cost-effective mass production, high material utilization, consistent batch-to-batch quality, minimal secondary processing, and low energy consumption.