Metal powder is the starting point of the powder metallurgy process, and its characteristics profoundly affect the mechanical and physical properties of sintered parts.

However, how to make metal powder remains a complex process to these days. Fortunately, manufacturers continually update their powder production technology.

Let’s take a look at the various metal powder production methods.

Contents

Atomization Process

You may know that gas and water atomization are common methods for producing metal powders. They all break up liquid metal into droplets and then atomize them into powder. Water atomization is known for its large production volume and low cost but results in powders with high oxygen content and irregular shapes. In contrast, gas atomization produces powders with lower oxygen content and more spherical shapes. Gas atomization is mainly used to produce easily oxidized metal such as titanium powder and stainless steel powder, while water atomization is commonly used for producing iron powder.

To combine the advantages of both methods, manufacturers have developed hybrid atomization technology. In this process, the molten metal is first atomized by gas and then by water.

Höganäs, a world-leading metal powder manufacturer, has developed vacuum induction melting inert gas atomization (VIGA). VIGA combines vacuum induction melting with inert gas atomization to achieve superior powder properties. It is particularly suitable for applications that require high purity and controlled particle size distribution.

Chemical Decomposition

Chemical decomposition processes are used for making powders from metal carbonyls and metal hydrides.

Iron powder and nickel powder obtained by chemical decomposition method have very small particle sizes, ranging from about 1 to 8 μm.

Nickel carbonyl is created by reacting nickel blocks and nickel-containing materials with carbon monoxide at 160°C. This process requires a pressure of 100-240atm. After nickel carbonyl is desorbed on the nickel block, it is decomposed into pure nickel powder at a temperature of about 230°C

Typically, carbonyl iron powder particles are spherical and have an onion-skin structure. Besides, carbonyl iron powder particles are spherical and very fine (>10 µm), in contrast to nickel powder particles which are very irregular.

Reduction

Apart from the atomization process, your manufacturers often use the reduction method to manufacture iron powder. This process reduces the ore using carbon or hydrogen.

First, iron oxide is reduced with carbon monoxide to obtain iron powder. These metal powders have high oxygen content, poor compressibility, and are not suitable for molding.

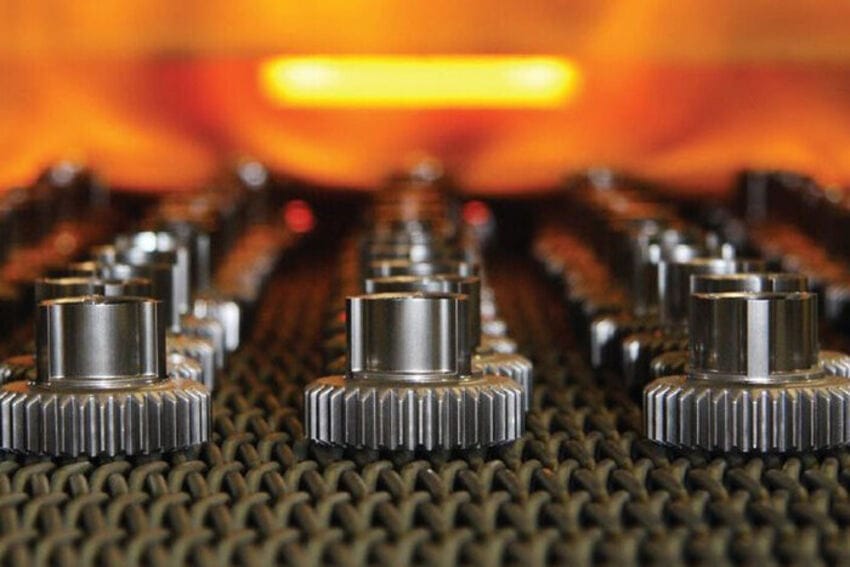

Then, the reduced iron powder is annealed and decarburized at 800 to 900°C in a steel belt furnace. Finally, it is crushed and sieved to obtain sponge iron powder with good compressibility and low oxygen and carbon content.

Compared with water atomized powder, the iron powder produced by the reduction has an irregular appearance and many cavities inside, commonly known as sponge iron powder.

In addition, powder metallurgy materials manufacturers utilize reduction to adjust the bulk density of water atomized copper powder. This process is to oxidize the water atomized copper powder in air and then reduce it to 500℃. The bulk density of copper powder can be reduced to 2.0g/cm3. However, during the oxidation and reduction process, the copper powder is prone to agglomeration and requires subsequent crushing.

Reduction has these advantages:

- High purity of metal powder, purity exceeds 99.5%

- Produces finer powder

- High production efficiency

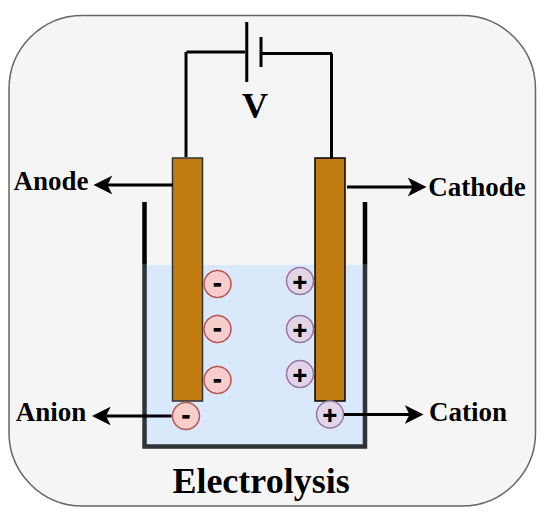

Electrolysis

Electrolysis is ideal for producing copper powder and iron powder.

In the electrolytic cell, the anode is a copper block, the cathode is high-purity copper or stainless steel, and copper sulfate is used as the electrolyte. During electrolysis process, copper ions are released from the anode and deposited on the cathode.

This process is similar to electroplating. The electrolytic copper powder obtained can be washed, filtered, dried, annealed and crushed to obtain high-purity copper powder. Generally, the copper content is 99.5%, and the oxygen content is below 0.05%.

Electrolytic iron powder has high compressibility, high toughness and high magnetic properties. Electrolytic copper powder has the following advantages

- High purity

- Good compressibility

- Good green strength

- Low apparent density (about 0.55 to 3.5g/cm3)

However, electrolysis process is costly and prone to pollution.

Mechanical Processing

For brittle metals, manufacturers obtain the required powders through mechanical processing, including:

- Attritoring

- Compression

- Milling

This process has a low yield and the powder is easily contaminated.

When using mechanical methods to make metal powders, be careful that the metal powder temperature rises and causes combustion problems. This problem is more serious for highly reactive powders, such as titanium powder.

Characteristics of Metal Powder

When you produce sintered parts, you have to take into account the properties of powdered metal.

Particle Size:

Generally, metal powders have a particle size between 1 and 1000 microns. Particle size measurement methods include laser scattering, sieving and microscopy. Common particle shapes include granular, spherical, flake, and dendritic.

Surface Area

For sintered parts, the larger the surface area of the powder, the higher its energy, the less stable it is, and the easier it is to sintering process.

Bulk Density

Bulk density is measured by filling a known mass of powder into a known volume of container. The higher the bulk density of the powder, the less friction between the powders, and the easier it is to fill the mold.

Particle Size Distribution

A narrow distribution makes it easier to uniform packing and processing

Tapped density

Tapped density is a measure of the density of a powdered material after it has been “tapped” or compacted. It is used to measure the packing efficiency of the powder.

Flow Rate: Represents the friction between the powders. It is affected by the powder particle size and shape

Compressibility

It refers to the ability of the powder to decrease in volume under an applied pressure. High compressibility indicates that the powder can achieve a high density during compaction process, which is essential for producing strong and durable components.

Chemical Composition

The chemical composition of metal powders needs to meet the material standards of the industry. Certain elements affect the mechanical properties of parts, such as carbon content, which affects the strength, ductility and toughness of the product.

Comparison of Metal Powder Production Methods

Since most powders are made by gas atomization, water atomization, chemical decomposition, and reduction methods, we provide you a quick comparison.

| Process | Gas Atomization | Water Atomization | Chemical Decomposition | Reduction |

|---|---|---|---|---|

| Metal | Titanium, Stainless steel, high speed steel | Iron, high speed steel, stainless steel | Nickel carbonyl, Iron carbonyl | Iron |

| Particle Size | 10 to 300 μm with SD ≈ 2 | Median: 50 to 100 μm | <10 μm | <150 μm |

| Particle Shape | Spherical | Irregular | Spherical or hedgehog-shaped | Irregular |

| Pros | Low oxygen content High green density | Good green strength High yield | High sintering density | With gaps Low cost High green strength |

| Cons | Weak green compact Low fine powder yield | High oxygen content | High price | Low green density |

| Application | Powder Metallurgy, MIM, 3D printing | Metal Injection Molding | Metal Injection Molding | Conventional PM process |

Precautions for Handling Metal Powder

Safety is the top priority in the production of metal powders.

Metal powders can easily cause allergic problems for workers. In addition, dust is also a serious problem. It is well known that most powders larger than 10μm will be filtered out by the human body’s filtration system. However, powders smaller than 1μm (The diameter of cigarette smoke particles ranges from 0.01 to 1 μm) are easily inhaled into workers’ lungs and enter the blood through the alveoli.

For PM2.5, China, the United States, and Japan have the following regulations.

When the powder particle size is very small, you have to pay attention to the problem of spontaneous combustion, and transportation and storage must be careful.

| Country | China | US | Japan |

|---|---|---|---|

| Annual Average (μg/cm³) | 35 | 12 | 15 |

| Daily Average (μg/cm³) | 75 | 35 | 35 |

FAQ

1. Which Method is Suitable for Producing Iron Powders?

Most iron powders are produced by one of two processes: reduction or water atomization.

Water atomization has good economic efficiency and large output.

The sponge iron powder produced by the reduction method has an irregular powder shape and a good mechanical locking effect.

Moreover, the particle size is mostly above 20 microns, which is suitable for making high-strength and complex-shaped parts. It is also suitable for making oil-containing bearings.

2. What is the Flow Rate of Iron Powder?

Generally speaking, the average flow rate of iron powder is 25 to 35 s/50g.

Taking ATOMET DB46 as an example, the flow rate measured according to the test method ISO4490 is 25.62s/50g.

3. What is Nano Metal Powder?

Nano metal powder refers to powder less than 100nm (0.1μm). Nano powder has extremely small particle size, high activity, and is easy to oxidize.