The High demand for titanium powder and titanium alloy powder in advanced manufacturing has led to a huge growth in this industry. Some industrial experts suggest that this industry is estimated to grow at a CAGR of over 14% by 2034.

Titanium powder has exceptional biocompatibility, strength-to-weight ratio, and corrosion-resistant properties that results in its vast applications in aerospace, medicine, automotive, and in electronics. So whatever you want high-strength auto parts or lightweight, durable aerospace engine components, titanium metal powder is an ideal material.

Contents

Properties of Titanium Powder

Here is a closer look at its properties:

- High Strength-to-Weight Ratio: Titanium shows a high strength-to-weight ratio; it is stronger and about 45% lighter than steel.

- Ductility: Highly ductile and it can easily be molded to form various shapes.

- Fatigue Resistance: This material is proven to show excellent resistance to cyclic stress

- Corrosion Resistance: Ti can form a stable oxide layer (TiO₂) that protects it from oxidation and rusting.

- Reactivity: Ti shows reactivity at high temperatures, especially with oxygen, nitrogen, and hydrogen

- High-Temperature Stability: It can withstand temperatures up to 300°C without losing structural integrity

- Biocompatibility: Ti powder is non-toxic and hypoallergenic, which it can be used in medical implants and prosthetics

| Property | Value |

|---|---|

| Molecular Weight | 47.86 (for bulk titanium metal) |

| Appearance | Silvery |

| Melting Point | 1668 °C |

| Crystal Structure | Hexagonal |

| Vickers Hardness | 830–3420 MPa |

| Boiling Point | 3560 °C |

| Density | 4.54 g/cm³ |

| Heat of Vaporization | 425 kJ/mol |

| Heat of Fusion | 14.15 kJ/mol |

| Tensile Strength | 140 MPa |

Types of Titanium Powder and Their Manufacturing Techniques

There are various manufacturing techniques for producing powder titanium depending upon the required properties and applications .

Gas Atomized Titanium Powder

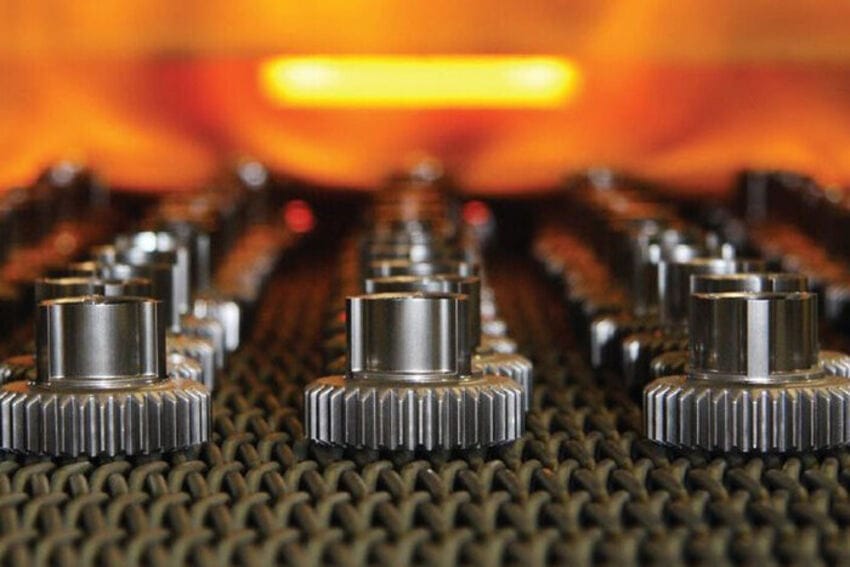

Gas atomized titanium powder is done by using an inert gas such as Argon(Ar). First of all, the metal is melted in a high-temperature furnace. Then, molten titanium is atomized leading to the breakdown of metal into fine droplets. Finely these droplets are converted into powder form when cooled.

Titanium powder obtained in this method shows these excellent properties

- Highly spherical particles with smooth surfaces

- Excellent flow ability

- Controlled particle size distribution

- Minimal impurities due to an inert gas environment

Plasma Atomized Titanium Powder

In this method, the titanium metal rod melts with the help of a plasma torch. Then, the molten titanium is atomized using a high-velocity gas stream. As a result, Spherical pure titanium powder is obtained. The yield of Ti-6Al-4V fine powder obtained by plasma atomization is greater than 40%.

Ti obtained through this method shows these characteristics.

- Ultra-fine spherical titanium powder

- Excellent flow ability

- Very low oxygen content

- Highly pure ti powder

Hydride-Dehydride (HDH) Titanium Powder

Hydride titanium powder is produced by hydrogenating Titanium sponge, scrap, or mill products. After hydrogenation, these products become brittle and then ground to a fine powder. Furthermore, dehydrogenation is done to obtain titanium metal powder.

Such ti powder shows:

- Irregular-shaped particles

- Rough surfaces

- Higher oxygen content compared to atomized powders

Titanium Sponge Powder

Titanium sponge powder is the primary product formed by reducing titanium oxide or titanium tetrachloride in the presence of magnesium or sodium. This metal powder has voids and interconnected gaps leading to the porous appearance. Just like pure titanium metal powder it also shows exceptional features like highly resistant to corrosion and high strength while maintaining low weight.

Uses of Titanium Powder

Titanium and titanium alloy powders are widely used in additive manufacturing, metal injection molding, hot isostatic pressing and cold spray applications, each with a specific particle size distribution.

Additive Manufacturing (3D Printing)

Additive manufacturing is used to produce lightweight, high-strength titanium parts with intricate geometries. This technique includes precise deposition of material layer-by-layer from digital models. Different technologies require specific titanium powder sizes: Selective Laser Melting (SLM) works best with 20-45 μm particles, while Electron Beam Melting (EBM) employs coarser 45-106 μm powders.

Metal Injection Molding (MIM)

MIM is an advanced technique which is used to produce highly accurate and complex components weighing less than 100g. In this technique,45μm titanium metal powder is used as a raw material where it is mixed with binder for the preparation of feedstock. This feedstock is fed to an injection molding machine where the final mim part is obtained after degreasing and molding.

Aerospace & Defense Industry

Since it shows a high strength-to-weight ratio and corrosion resistance in extreme environments. It is used in the manufacturing of aircraft engine components, spacecraft structures, and armour plating for military vehicles.

Biomedical & Healthcare Applications

Titanium alloy powder, such as Ti-6Al-4V powder is highly biocompatible and low elastic modulus . That is why it is used in orthopaedic implants (hip, knee, spinal implants), and dental implants.

Automotive Industry.

Its lightweight and high strength enables it to improve fuel efficiency and durability

Leading to its use in manufacturing of lightweight engine components, brake systems, and exhaust systems.

Advantages of titanium powder

High strength-to-weight Ratio

One of the biggest advantages of titanium is its excellent strength-to-weight ratio. This unique characteristic makes it ideal for industries like aerospace. Engineers utilize titanium powder to manufacture high-strength, lightweight components that offer exceptional durability and performance.

Corrosion resistance of Titanium Powder

Components made from titanium metal powder show excellent corrosion resistance due to the uniformity in their nature. Thus titanium powder is resistant to different media, including saltwater, acids, and industrial chemicals. Moreover titanium metal powder coating is widely used to enhance the corrosion resistance of components.

Titanium Powder Manufacturer

Here are the three leading manufacturers of Titanium Metal powder:

American Elements

American Elements is considered one of the top global suppliers of metal powders. They manufacture 99% to 99.9% pure titanium metal powder. They also offer custom particle sizes ranging from nano scale to microns.

Stanford Advanced Materials

The company was established in 1994 and specializes in producing advanced materials. They offer Grade 1-5 level titanium powder including Ti-6Al-4V-ELI.

Höganäs AB

Höganäs AB is a world leader in metal powder solutions. The company focuses on production of materials for additive manufacturing. They are major producers of gas-atomized spherical Ti-6Al-4V and CP-Ti (Grades 1–4).

Titanium Powder Price

There are several factors that affect the titanium metal powder prices:

- Chemical Composition: Pure titanium of Grade 1-4 is cheaper than Grade 5 titanium powder such as from Ti-6Al-4V. Because grade 5 titanium includes alooying that enhances its cost.

- Quantity: If you purchase metal powder in bulk form it will cost less.

- Particle size: Fine particle 15-45 microns are more expensive than coarser powders

- Production process: It also affects the price of titanium metal powder such as Gas atomized powder customer than the powder produced through HDH process.

Here is the comparison of properties of pure titanium powder and its alloys

Here’s your data turned into a clean, easy-to-read table using your preferred style:

Here is your titanium materials comparison table, formatted in your preferred clean style:

| Property | Pure Titanium Powder | Ti-6Al-4V | Ti-6Al-7Nb |

|---|---|---|---|

| Composition | ~99.5%–99.9% Ti | 6% Al, 4% V, Balance Ti | 6% Al, 7% Nb, Balance Ti |

| Density (g/cm³) | 4.54 | 4.43 | 4.50 |

| Melting Point (°C) | ~1668 | ~1604–1660 | ~1800–1860 |

| Particle Size Range (μm) | 10–150 | 10–150 | 10–150 |

| Tensile Strength (MPa) | ~240–550 | ~900–1100 | ~900–1050 |

| Yield Strength (MPa) | ~170–485 | ~830–900 | ~800 |

| Elongation (%) | 10–30% | 10–15% | 10–16% |

| Hardness (HRC) | N/A | ~30–40 | ~28–38 |

| Thermal Conductivity (W/m·K) | ~17–22 | ~6.7 | ~6.7 |

| Corrosion Resistance | Excellent | Excellent | Superior to Ti-6Al-4V |

| Applications | Biomedical, Aerospace, Chemical, Additive Manufacturing | Aerospace, Orthopedic Implants, 3D printing | Medical Implants (hip joints, dental implants) |

| Price (per kg) | $50–$500 | $150–$450 | $400–$750 |

Prices are for reference only.

Safety Precautions

When dealing with titanium metal powder strict safety precautions should be adopted due to its highly reactive and flammable nature. It should be stored in air tight containers made with non-reactive material because it is highly explosive when in contact with spark, flam or static current. Personal protective equipment (PPE) should be used while handling metal powder. In case of spill titanium powder should not be cleaned using traditional methods instead class D fire extinguishers and non-sparking tools should be used.

Compared to forged and machined parts, metal powder products offer significantly higher material utilization and lower energy consumption. As a leading powder metallurgy company in China, BLUE is dedicated to advancing the use of powder metal parts and supporting sustainable development.

We provide a full range of standard powder metallurgy parts, along with customized services. Our capabilities cover both powder metallurgy and injection molding.

FAQ

1. What is Titanium Dioxide Powder?

Titanium dioxide (TiO₂) is a white pigment powder. It is used in paints, cosmetics, and sunscreens for its brightness and UV resistance.

2. What is Titanium Dioxide Mainly Used for?

It is mainly used in paints, coatings, plastics, cosmetics, and food as a whitening agent and UV blocker.

3. Is Titanium Powder Explosive?

Finely powdered titanium can be flammable and explosive in the air when it is exposed to high temperatures or sparks. Due to Titanium Powder fire catching property it is used in fireworks.