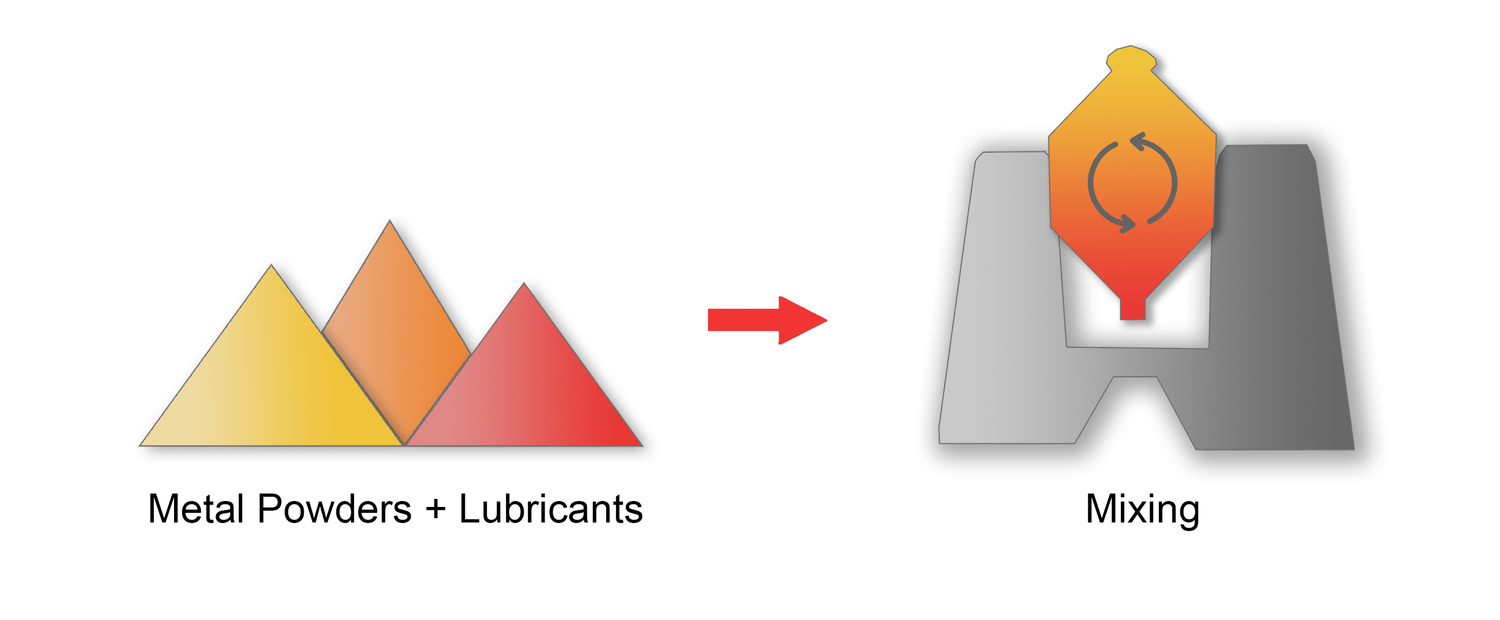

Combine powders, alloying elements, and lubricants to determine the characteristics of finished product. This process is referred to as blending or mixing.

The purposes of powder blending include:

- Achieving a uniform powder particle size.

- Adding lubricants to improve the fluidity of metal powders and reduce friction during die compaction.

- Incorporating alloying elements to enhance the specific properties of powder metallurgy parts.

Contents

Steps of Blending in Powder Metallurgy

Blending process usually has the following steps.

Choose Metal Powders

Choose the raw material for blending process, including basic metal powders and alloying elements.

Metal powders are the cornerstone of the powder metallurgy process, influencing the performance of the finished component. And alloying elements directly improves the corrosion resistance and mechanical strength of parts.

Commonly used powder metals include:

- Iron

- Copper

- Aluminum

- Tungsten

- Stainless steel

Main alloying elements are as follows.

- Nickel (Ni)

- Chromium (Cr)

- Molybdenum (Mo)

- Manganese (Mn)

Usually, these alloying elements are added to the molten metal during powder production and then atomized into metal powders. This is known as prealloyed powders.

Weight and Proportioning

After selecting the powders, calculate the weight percentages for each material based on the final product’s requirements.

Blending

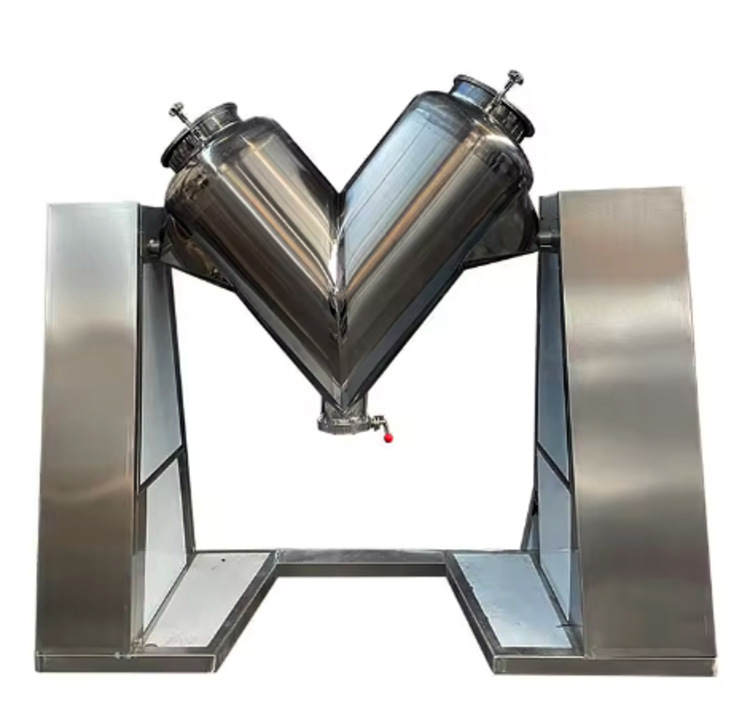

During blending process, metal powders are mixed by blending equipment, such as V mixer. The purpose of blending process in powder metallurgy is to make even metal powders.

According to the needs, you can adjust the speed and swing amplitude appropriately to achieve a better mixing effect.

Powder metallurgy mixers have a feed inlet and an outlet for easy operation. And it can mix raw materials ranging from several hundred kilograms to a ton at a time. Usually, mixing 1,000 kg of metal powder takes about 1 hour.

The time and speed of blending process are carefully controlled to prevent demixing. This is when powders separate because of differences in density or particle size. In addition, mixed metal powders are typically kept for no more than a week.

Adding Binder and Lubricant

Binders offer essential adhesion between the particles. This helps mixed powders remain intact during the following compaction process.

Main binders are as follows:

- Polyvinyl alcohol (PVA) is a water-soluble synthetic polymer with excellent bonding properties. It has good bonding properties and is easy to remove after heating with minimal residue.

- Wax-based binders, like paraffin wax, can form a strong green body.For example, alcohol dissolves paraffin wax and mixes it into tungsten carbide powder. After the alcohol evaporates, the paraffin wax helps to bind the tungsten carbide powder. It is also easy to melt and evaporate.

Lubricants reduce the friction between metal particles, which makes it easier for the powders to flow when mixed. It makes the mixing process smoother and more efficient.

- Zinc stearate has good lubrication effect and is suitable for iron-based structural parts

- Acrawax has a lower lubrication effect than zinc stearate, but it can be completely removed by pre-sintering without leaving any residue.

Testing Mixed Metal Powders

Metal Powder attributes such as flow rate and density are examined to ensure compliance with standards. Evaluate

Testing mainly include:

Flow rate

Flow rate shows how fast the powder flows through a funnel or orifice. A higher flow rate indicates easier handling. Factors such as particle shape, size, and texture affect it.

Bulk Density

Bulk density measures the mass per unit volume of the powder when poured into a container. It shows how densely the powder will pack together when compacted. A higher bulk density suggests the powder will form denser, more stable parts.

Particle Size

The size of powder particle influences how they mix, flow, and pack together. When particle sizes are similar throughout, it assists the mixture stay even and ensures the final product is consistent. Particle size analysis uses techniques like sieving or laser diffraction to ensure consistency.

Chemical Composition

Contaminants such as sulfur, phosphorus or oxygen can lead to poor mechanical properties and other defects. Analyze chemical composition to avoid defects.

The following are the parameters of several metal powders.

Material | Flow Rate | Bulk Density | Particle Size | Chemical Composition |

Copper powder | / | 3.76 g / cm3 | 45 µm / 325 mesh/ 0.045 mm | Cu 99,96% (Al) Aluminium : 0.004% Max (Cd) Cadmium: 0.001% Max (Pb) Lead : 0.001% Max |

Iron powder | 26.3 s/50g | 2.94 g / cm3 | 140 µm / 105 mesh / 0.140 mm | Carbon (C) : 0.004% Sulfur (S) : 0.0101% Oxygen content (O): 0.08% Manganese (Mn): 0.179% |

Stainless steel powder 316L | / | 2.82 g / cm3 | 45 µm / 325 mesh / 0.045mm | Ot: 0.39 Carbon (C) : 0.038% Molybdenum (Mo): 2.90% Silicon (Si) : 0.48% Chromium (Cr): 16.00% Nickel (Ni): 13.40% |

Factors Affecting Blending in Powder Metallurgy

Several key factors influence the powder metallurgy mixing process:

Powder Size and Distribution

Uniform particle distribution promotes better powder cohesion, reduces voids, and results in a more balanced mixture. Smaller particles mix more smoothly, improving powder flow and compaction. This helps powder metal parts reach consistent mechanical properties.

Powder Shape

Spherical particles easily slide over each other and blend well. Their smooth shape lowers friction, helping them to move and mix better.

Meanwhile, irregular or angular particles are different. They tend to lock together, forming a strong bond that makes the final product stronger. However, these irregular shapes can also disrupt smooth mixing, causing uneven blending.

Main Powder Mixing Equipment

Tumbler Mixer

A tumbler mixer features a cylindrical container that rotates on a platform. Its smooth interior stops powders from sticking and makes sure they mix evenly. It’s gentle and perfect for mixing fine metal powders without damaging them.

Double Cone Mixer

This mixer has two conical sections joined at the bases, forming a diamond shape. It rotates horizontally along its axis. This design is good for mixing powders of different sizes and densities. So it’s effective at creating uniform mixtures and preventing separation.

V Mixer

V mixer has a V-shaped chamber that spins around a horizontal axis. The V shape makes powders to slide and mix back and forth. This motion helps distribute the powders evenly and Precludes clumping.

Ribbon Blender

It has a U-shaped trough with two ribbon-like blades rotating in opposite directions, ensuring balanced distribution of powders. The blades push the powders back and forth, mixing them along the trough. This design is effective for large batches, minimizing segregation.

Planetary Mixer

Planetary mixers have a central mixing blade that spins on its axis while orbiting the container. This dual movement ensures thorough mixing and avoids segregation, creating a consistent blend. The mixer also ensures that the powders reach all areas of the container, reducing Inconsistent mixing.

FAQ

What is the Difference between Blending and Mixing in Powder Metallurgy?

Blending gently tumbles similar metal powders from different lots or size cuts to equalize chemistry, flow, and particle distribution without adding lubricants or alloying powders.

Mixing combines dissimilar powders and introduces lubricants or binders so each particle carries the complete formulation needed for compaction or molding.

Is Powder Metallurgy Mixing Process Eco-friendly?

Powder metallurgy mixing process is beneficial to the environment in some ways. It uses recyclable and Biodegradable materials, which helps minimize environmental damage.

Also, using mixing techniques that waste less and energy-efficient mixers facilitates in lower the carbon footprint

Does the Powder Metallurgy Blending Process Require a Separate Space?

Yes, the powder metallurgy mixing

needs a separate space. Dust can spread and harm air quality, so a dedicated area is important.

This space should include air purification and dust removal equipment to reduce the impact on the environment. Moreover, this process is a key concern for the China Environmental Protection Bureau.

Will the Powder Metallurgy Mixing Process Cause Physical Harm to the Workers?

Yes, handling metal powders can be harmful. Breathing in the fine dust can cause lungs problems. Besides, the powders can irritate skin or result allergies. That’s why it’s important to wear masks and gloves. It’s equally important to keep the workplace well-ventilated to protect workers’ health.