China Sintered Shock Absorber Part

BLUE delivers precision-engineered shock absorber parts, including valves, pistons, and guides, with tight tolerances of ±0.01 mm achieved through sizing process. Featuring excellent corrosion resistance and extended service life, our components are enhanced with surface treatments to meet your performance needs.

Why Choose BLUE?

We have established ourselves as a dependable supplier of high-quality shock absorber parts, offering free mold design service, fast shipping, and competitive prices.

BLUE High Quality Standards

BLUE guarantee your shock absorber components quality with ISO 9001:2015 certified quality management system. We provide a one-year warranty on your products.

Standard Shock Absorber Part Shop

BLUE has a full range of standard shock absorber parts in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

Free Mold Design Service

With over 20 years of expertise in mold design, BLUE offers free, high-precision mold design services to meet your customized needs. Let our experience work for you!

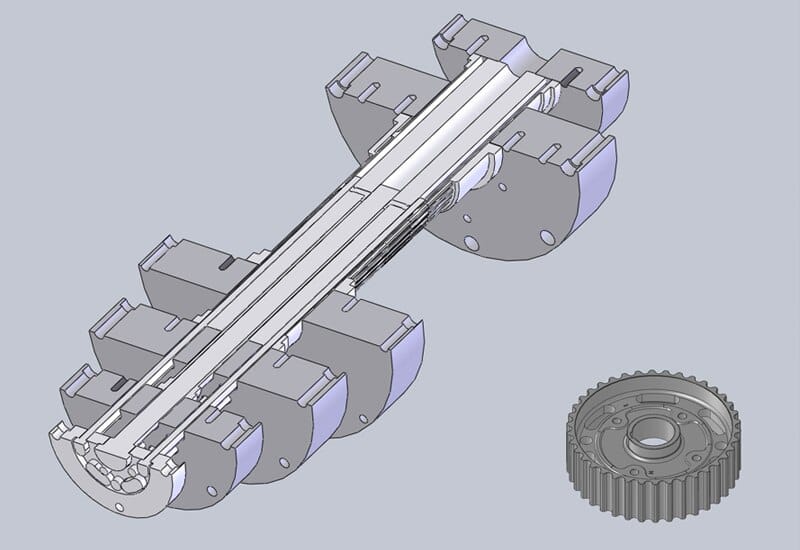

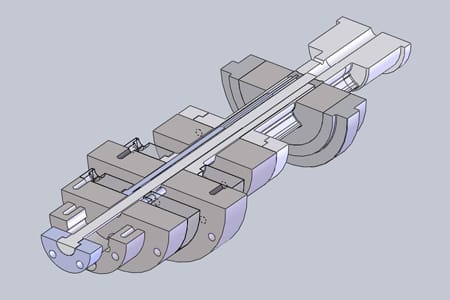

BLUE Shock Absorber Parts

BLUE offers a full line of standard shock absorber parts, as well as free samples and custom services to meet your needs.

Shock Absorber Components

BLUE shock absorber components are made of FC-0208 as raw material and sintered at high temperature to obtain mechanical properties.

Shock Absorber Auto Parts

Our shock absorber auto parts have strict dimensional tolerances, good resistance to shock, and long service life.

Shock Absorber Motorcycle Parts

BLUE shock absorber motorcycle parts has a density of 6.9g/cm3 and high precision, which can achieve good shock absorption effect.

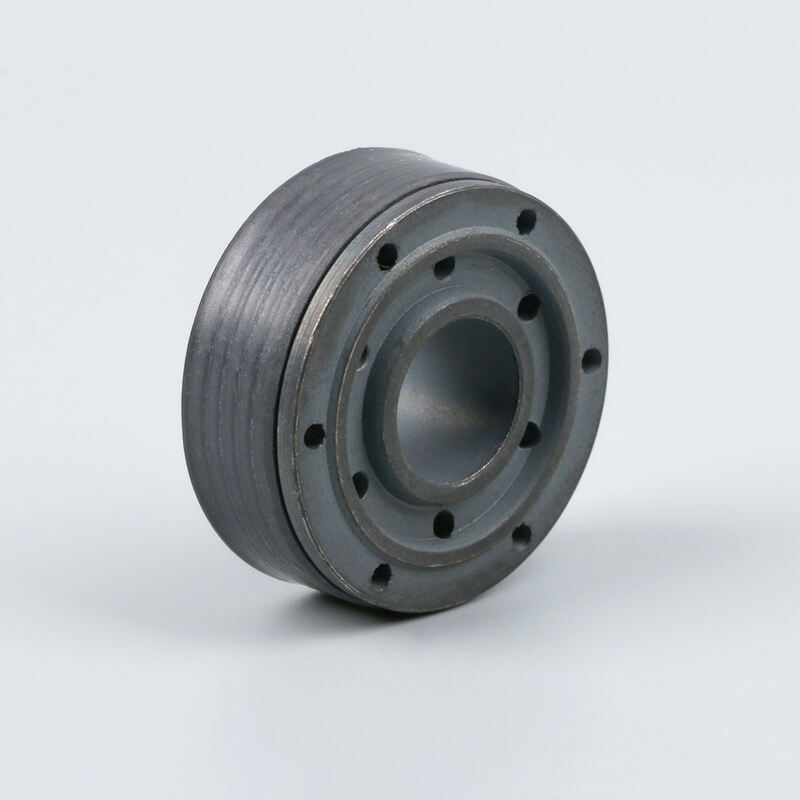

Shock Absorber Guide

Shock absorber guides prevent lateral movement, reduce friction, contribute to effective damping and extend the life of the shock absorber.

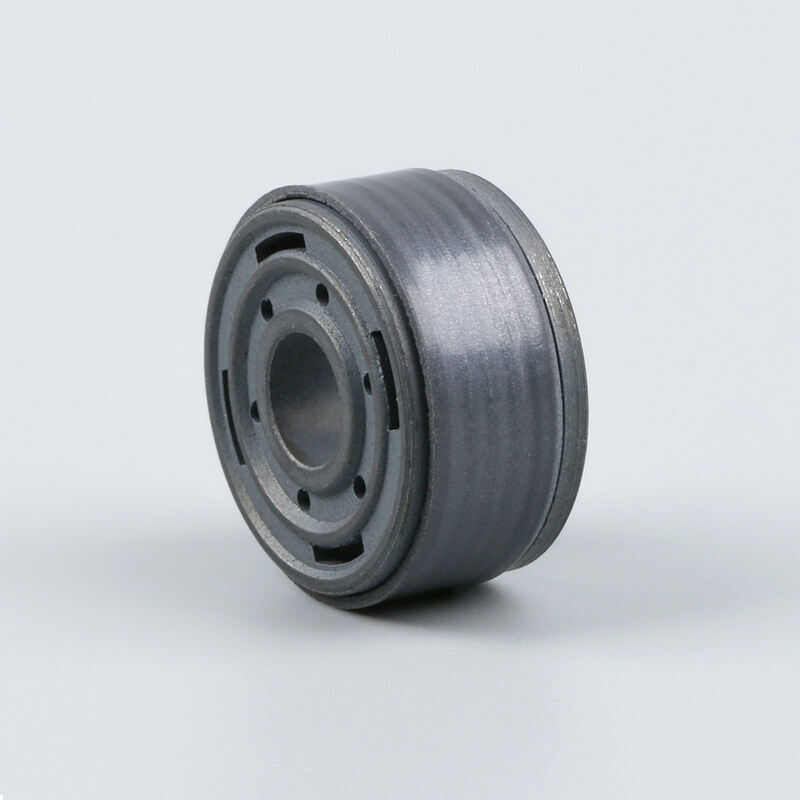

Shock Absorber Piston

Shock absorber piston moves up and down in the cylinder, and hydraulic fluid slowly passes through its small orifice to provide damping, slowing the spring movement.

Shock Absorber Valves

Our shock absorber valves precisely control fluid flow during compression and rebound to adjust suspension resistance.

BLUE Shock Absorber Part Advantages

BLUE’s shock absorber parts are manufactured under the strict standards of ISO 9001:2015 and IATF 16949:2016.

Our shock absorber parts comply with ISO 2768, with minimum tolerances controlled within ±0.01 mm after sizing process.

BLUE offers a variety of surface treatment processes, including steam treatment, machining, oil impregnation, electroplating, and Dacromet.

Standard Shock Absorber Auto Part

As an advanced powder metallurgy supplier, we offer a wide range of standard PM parts with no mold fees and fast delivery.

Our standard shock absorber parts include shock absorber valves, shock absorber pistons, and shock absorber guides.

Download our shock absorber product list for free to find the perfect match for your needs.

If you don’t find the standard parts you need, we also accept custom orders.

Functions of Shock Absorber Part

Shock absorber piston moves up and down inside the shock absorber cylinder, forcing hydraulic fluid slowly through precisely designed small valves to provide resistance to slow down the spring movement.

Shock absorber guide supports the piston rod, ensuring its precise alignment within the shock absorber.

Shock absorber valves control fluid flow during compression and rebound to adjust suspension resistance.

PM Shock Absorber Parts Benefits

Shock absorber parts are pressed with iron-based metal powder as raw materials, with high material utilization.

Powder metallurgy allows shock absorber components to achieve strict dimensional tolerances, precise part matching, and reliable shock absorption performance.

PM shock absorber parts can be impregnated with oil to provide a self-lubricating effect, extending their service life.

With precise control of the powder metallurgy process, shock absorber parts offer excellent quality consistency.

Standard Shock Absorber Parts Specifications

The following are BLUE’s standard shock absorber parts specifications, including density size, tolerance, surface roughness, etc.

| Attribute | Value |

|---|---|

| Material | MPIF 35 FC0205, FC0208, DIN 30910-4 |

| Density | 6.3-6.9g/cm3 |

| Hardness | 55-90 HRB |

| Surface finish | Ra 0.8μm to Ra 1.6μm |

| Diameter | 22-60mm |

| Length | 3.5- 17mm |

| Tolerance | ±0.01 mm |

Powder Metallurgy Parts Manufacturing Process

Powder metallurgy is a precision manufacturing process with a continuing and stable accuracy of up to 0.01mm, which requires strict control at each stage to ensure the quality of the final part. Any deviation or error during the process may result in the rejection of the entire batch.

Designing

Mold design is a critical process that must consider the desired part geometry, material properties, production volume, and cost-effectiveness.

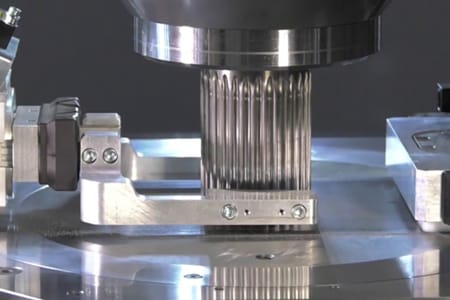

Tooling

Powder metallurgy tooling includes upper and lower punches, die, and core rod. The mold needs to have excellent strength, hardness and wear resistance.

Mixing

Mixing is the process of blending metal powder with binders to improve its uniformity and fluidity, promoting better material consistency.

Compacting

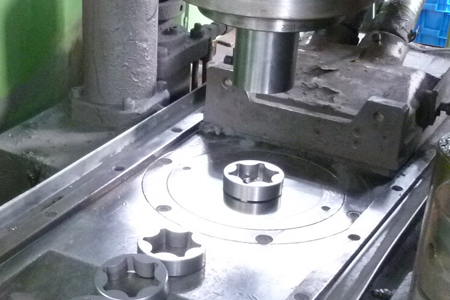

Conpacting is a process that presses metal powder into mold cavity through powder compaction machine to get a green compact part.

Sintering

Sintering heats the green compact to a temperature below its melting point in a controlled atmosphere to obtain the desired mechanical properties.

Sizing

Sizing corrects dimensional deviations after sintering and enhances product accuracy. It requires an additional, simpler set of molds compared to the forming mold.

Tumbling

Tumbling removes burrs and flash from a part's surface by vibrating it with abrasive media, such as stone or ceramic, resulting in a smoother finish.

Machining

Machining can achieve complex shapes that cannot be pressed by powder metallurgy, such as transverse holes and screw threads.

Blackening

Blackening process, or steam treatment, forms an oxide layer to prevent rust and increase hardness, offering a cost-effective solution.

Hardening

Hardening enhances the material's strength and hardness through carburizing or nitriding, resulting in improved wear resistance and fatigue life.

Inspecting

The inspecting process is always a critical step that ensures quality and performance through BLUE inspection standards before shipping.

Packaging

BLUE's packaging process uses anti-rust paper, vacuum, blister and other methods to ensure that the product is intact during transportation.

BLUE's Powder Metallurgy Product Manufacturing Equipment

BLUE has a complete range of advanced powder metallurgy production equipment, including 25T to 1000T compaction press, conveyor belt sintering furnace, vacuum sintering furnace, sizing press, CNC machining equipment, hardening furnace, etc.

Download Shock Absorber Part Product List

The following is a list of our standard shock absorber parts, including shock absorber guide, shock absorber piston, shock absorber valve body and seat.

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

A car shock absorber is a component of the vehicle’s suspension system that absorbs and dampens shock impulses from the road surface, enhancing driving comfort and vehicle handling.

The pistons, guides, and valves within the shock absorber are often made using powder metallurgy, which provides high dimensional accuracy and cost-effectiveness in production.

Shock absorbers are usually composed of the following key parts:

- Piston

- Piston Rod

- Cylinder

- Valves

- Guides

- Oil Seals

- Bushings

- Spring

These components work together to absorb and dampen shock impulses, enhancing driving comfort and vehicle handling.