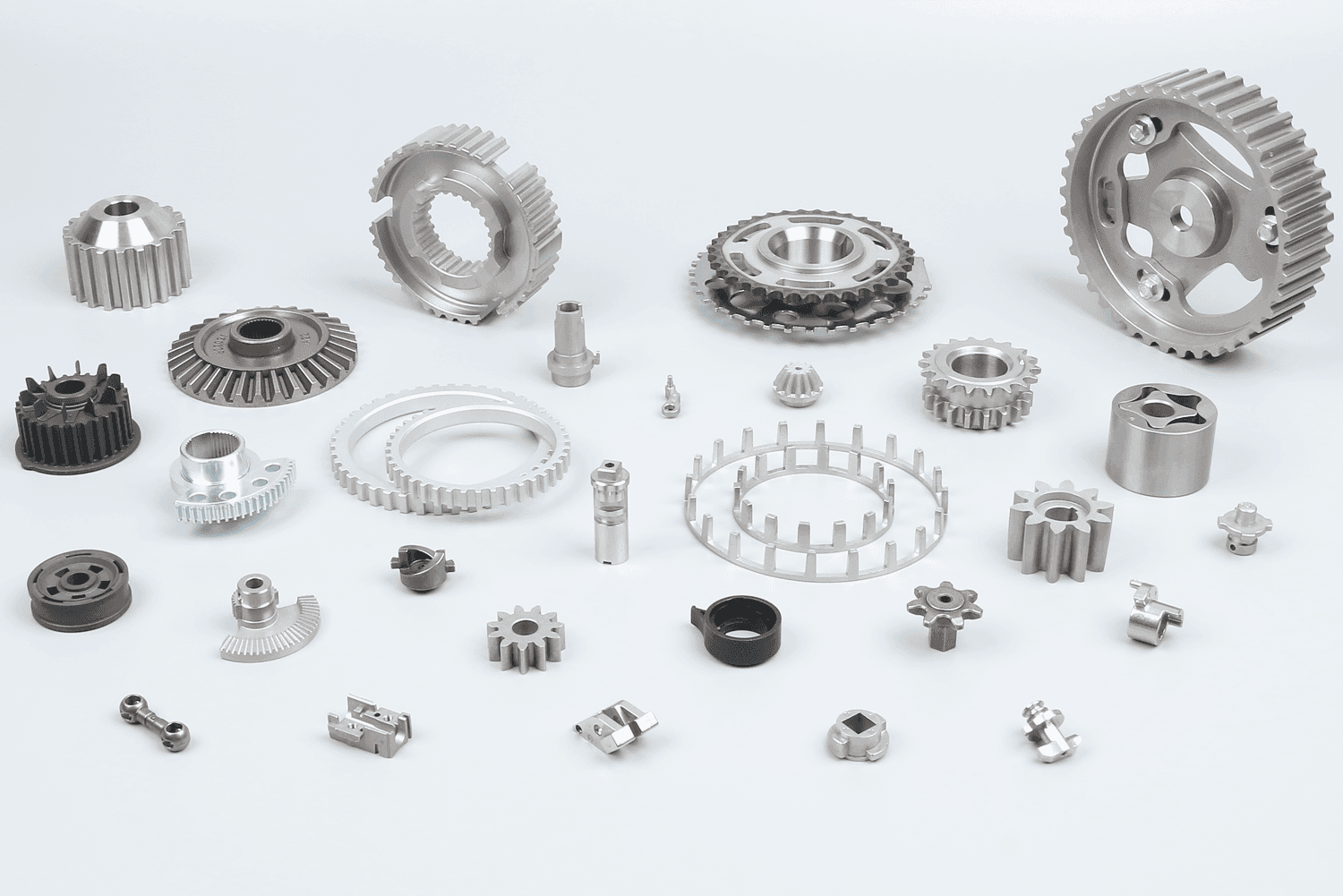

It is well known that powder metallurgy (PM) is an advanced manufacturing technique. PM forms parts from metal powder, offering high material utilization and fast production speeds.

Today, different types of powder metallurgy processes are applied in automotive, motorcycle, medical, and aerospace industries.

Let’s take a look at these different powder metallurgy processes overview:

- Conventional powder metallurgy process is a cost-effective manufacturing method for mass production of small and medium-sized structural parts.

- Metal injection molding can manufacture very small, high-density products with fine features.

- Powder forging combines PM with forging process to make high-performance products.

- Metal additive manufacturing is ideal for manufacturing small quantities of complex-shaped parts, even with hollow features.

- Cold isostatic pressing can produce large, three-dimensional shapes.

- Hot isostatic pressing can make finished products with 100% density.

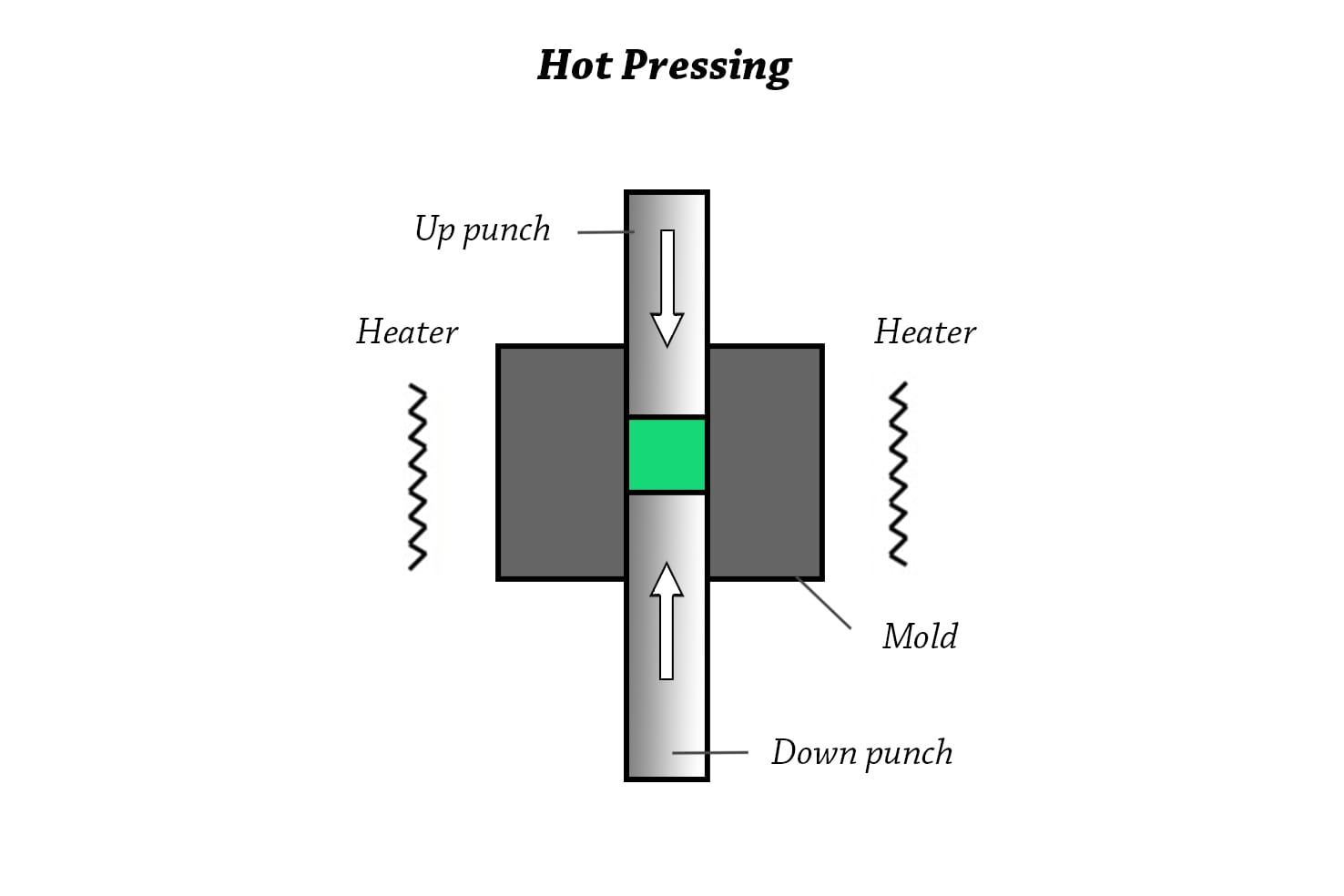

- Hot pressing is a densification process that applies pressure and heat to the mold and material at the same time.

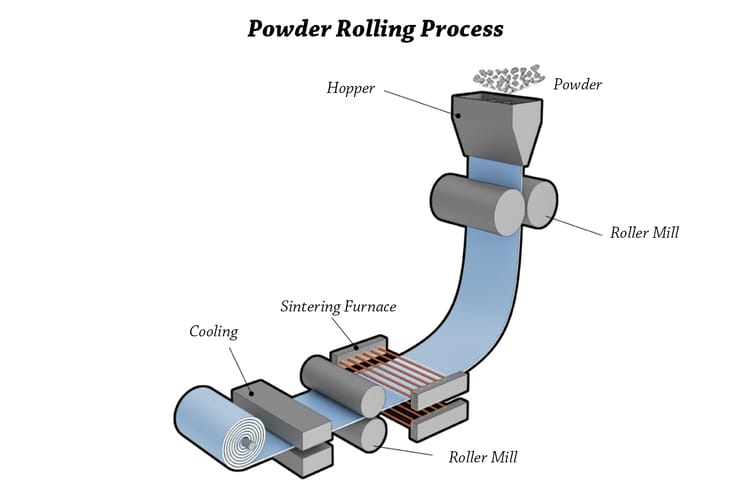

- Powder rolling is suitable for low-cost multi-layer material flat plates.

- Spray forming directly sprays molten metal into near-net-shape parts.

- Loose powder sintering is utilized for making sintered filters.

Contents

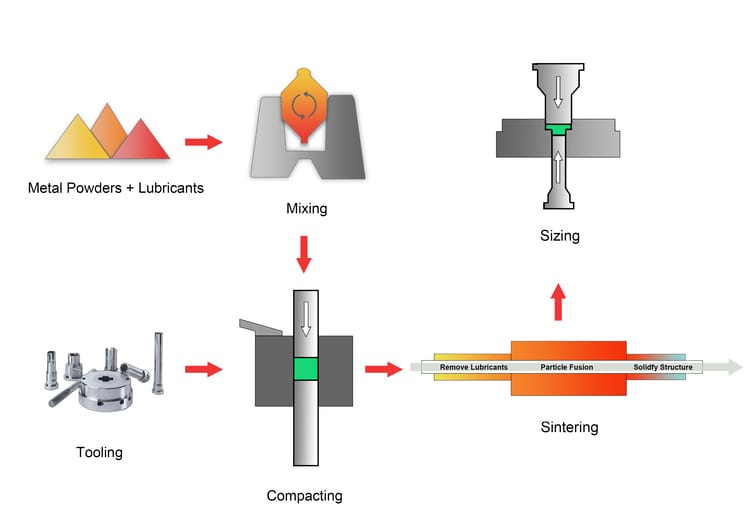

Conventional Powder Metallurgy Process

The conventional powder metallurgy process is to press the powder into green parts through a powder compaction press. Then you sinter the green parts to improve their density, strength, and other mechanical properties. However, due to the inherent porosity of press-and-sinter technology, components produced by a typical powder metallurgy manufacturer generally achieve densities below 95%, unless secondary operations such as copper infiltration or hot isostatic pressing are applied.

Components manufactured by conventional powder metallurgy processes exhibit consistent quality across production batches, provide clear cost advantages in high-volume manufacturing, and achieve high material utilization.

| Attributes | Typical |

|---|---|

| Component Mass (g) | 0.1–10,000 |

| Surface Roughness (μm) | 2 |

| Wall Thickness (mm) | 2 + |

| Production Volume | 2000 + |

| Density (%) | 85–90 |

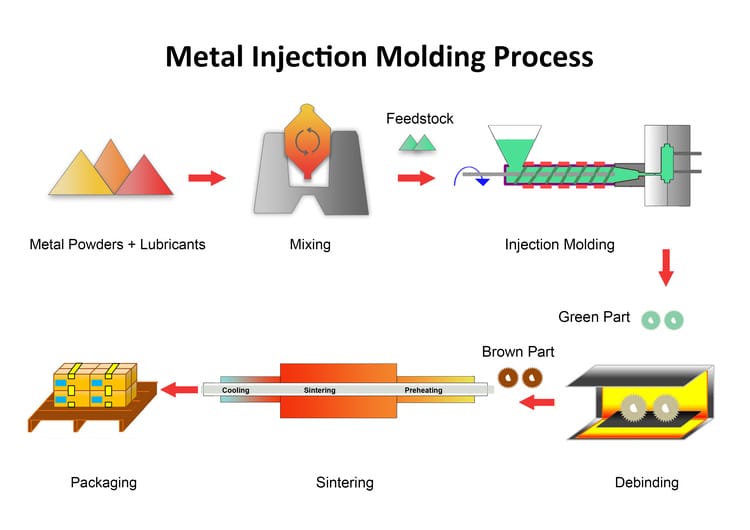

Metal Injection Molding Process

Metal injection molding is suitable for manufacturing small products with high density and fine features. It was developed from ceramic injection molding.

MIM process mainly includes the following four stages:

- Binder and metal powder are evenly mixed in a ratio of 40:60 to obtain feedstock.

- Metal powder is melted and injected into the mold by the injection molding machine.

- Your manufacturers pass the unfinished product through a heating furnace to remove binders.

- The degreased product is sent to a sintering furnace to increase strength.

The following table shows some typical features of metal injection molded products.

| Attributes | Typical |

|---|---|

| Component Mass (g) | 0.1–10,000 |

| Surface Roughness (μm) | 2 |

| Wall Thickness (mm) | 2 + |

| Production Volume | 2000 + |

| Density (%) | 85–90 |

Powder Forging Process

Metal powder is pressed into the desired shape, then pre-sintered or sintered, and forged—either cold or hot, depending on the requirements. This process is referred to as powder forging (PF) or powder metallurgy forging. PF can increase the density of sintered parts to 99%. It’s the preferred method for producing high-strength components like connecting rods.

Metal Additive Manufacturing Process

Metal additive manufacturing (MAM) is the latest powder forming technology, renowned for rapid prototyping. MAM can produce products with complex features that cannot be produced by other processes. AM also does not require molds, which is very beneficial for small batches of products.

Most metal additive manufacturing processes follow these steps:

- First, you spread a layer of metal powder on a flat surface.

- Then, a metal 3D printer melts and sinters the powder at specific coordinates using a laser or electron beam.

- After one layer is complete, you add another layer of powder on top.

- The laser or electron beam continues to sinter the powder according to the programmed design.

- In this way, the product is built up layer by layer from the powder.

The ASTM F2792 standard classifies 7 different types of additive manufacturing technologies:

- Powder Bed Fusion

- Binder Jetting

- Directed Energy Deposition

- Sheet Lamination

- Material Extrusion

- Material Jetting

- Vat Photopolymerization

Cold Isostatic Pressing Process

Cold isostatic pressing (CIP), as the name suggests, is a material processing method conducted at room temperature. It is suitable for components with a large length-to-width ratio, complex shapes, or requirements for uniform density.

Typically, you start by filling a metal powder into a flexible mold. Thus, you immerse the mold in oil or water to press it.

The mold is subjected to pressure from all sides, so the green density is relatively uniform.

In ordinary pressing, the mold is prone to wear. Therefore, it is mostly made of tool steel or cemented carbide and is expensive.

In contrast, cold isostatic pressing molds are made of rubber or polyurethane rubber and are cheaper.

The disadvantage of CIP is that it is hard to produce parts with precise dimensions. If you want products that meet dimensional accuracy, the sintered parts need secondary processing.

Cold isostatic pressing is divided into two forming types: wet bag and dry bag.

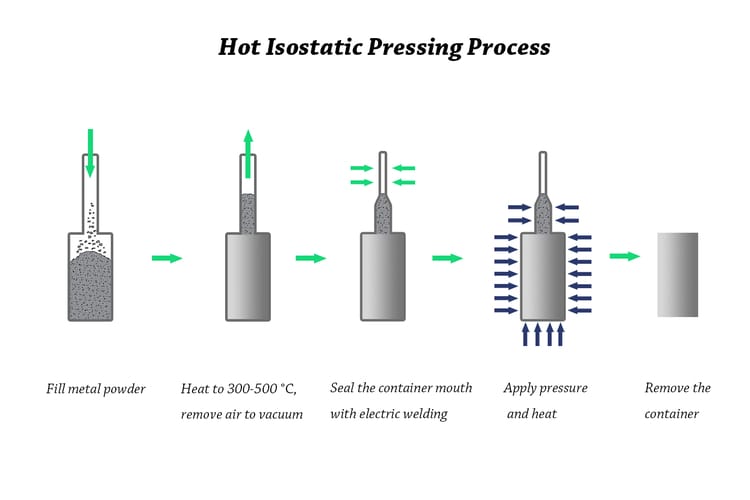

Hot Isostatic Pressing Process

Hot isostatic pressing (HIP) is a process that subjects parts to both high temperature (500-2000°C) and isostatic pressure (100-200 MPa) in a protective gas (e.g. argon or nitrogen).

You might be aware that hot isostatic pressing produces powder metallurgy product with full density and no pores.

Therefore, HIP is often applied to densify metal injection-molded parts and castings.

- Pour the powder into a jar with a wall thickness of 2-3 mm. Then, you heat it to 300-500 °C and evacuate the inside.

- Seal the opening of the jar with electric welding, which is called encapsulation.

- You place the sealed jar in a heating chamber to heat it and pass argon or nitrogen to pressurize it.

- Finally, after removing the container through CNC machining, you obtain a product with 100% density.

Hot Pressing Process

Hot pressing combines the steps of pressing and sintering into one. In this method, a powder is placed in a die and subjected to both heat and pressure at the same time. Unlike isostatic pressing, hot pressing is uniaxial pressing

Hot pressing is mainly applied in manufacturing diamond tools, friction materials, and sputtering targets.

In most cases, the diamond tool manufacturing process is as follows:

- Metal powder and diamond particles are mixed and filled into a graphite mold.

- Then an electric current is passed through the mold and the powder is heated by the owner.

- When the given temperature is reached, the press compacts the powder into green parts.

Besides, the green parts are closely related to pressure and temperature.

Powder Rolling Process

Rolling is a traditional metallurgical manufacturing process commonly used in steel plate production. It flattens steel billets by passing them through rollers to achieve the desired thickness.

Rolling can be utilized in the powder metallurgy industry.

Powder rolling is a powder forming technique that turns powder into thin sheets by passing it through rolls, followed by sintering.

Sometimes, in order to achieve higher density, the sintered product is hot rolled again and then cooled.

Spray Forming Process

Spray forming is similar to the gas atomization process and is a near-net-shape process.

The metal liquid breaks into fine droplets under high-pressure gas. Then these droplets are deposited on a substrate, gradually building up and finally solidifying.

Spray forming offers several advantages:

- The finished product has a fine structure, resulting in good mechanical properties.

- High droplet temperatures ensure immediate adhesion to the substrate, preventing surface segregation.

- The final product density can exceed 98%.

- Spray forming can produce near-net-shape products in one step, lowering production costs.

- It can use composite materials to create products.

However, it is limited to the shapes of products that can be manufactured. Common ones include cylindrical billets, plates, and hollow tubes.

Loose Powder Sintering

Loose powder sintering fills the powder into a graphite or ceramic mold and vibrates it to improve packing density and integrity. The powder and mold are then sent into the sintering furnace together. This is the main manufacturing method of sintered porous filters.