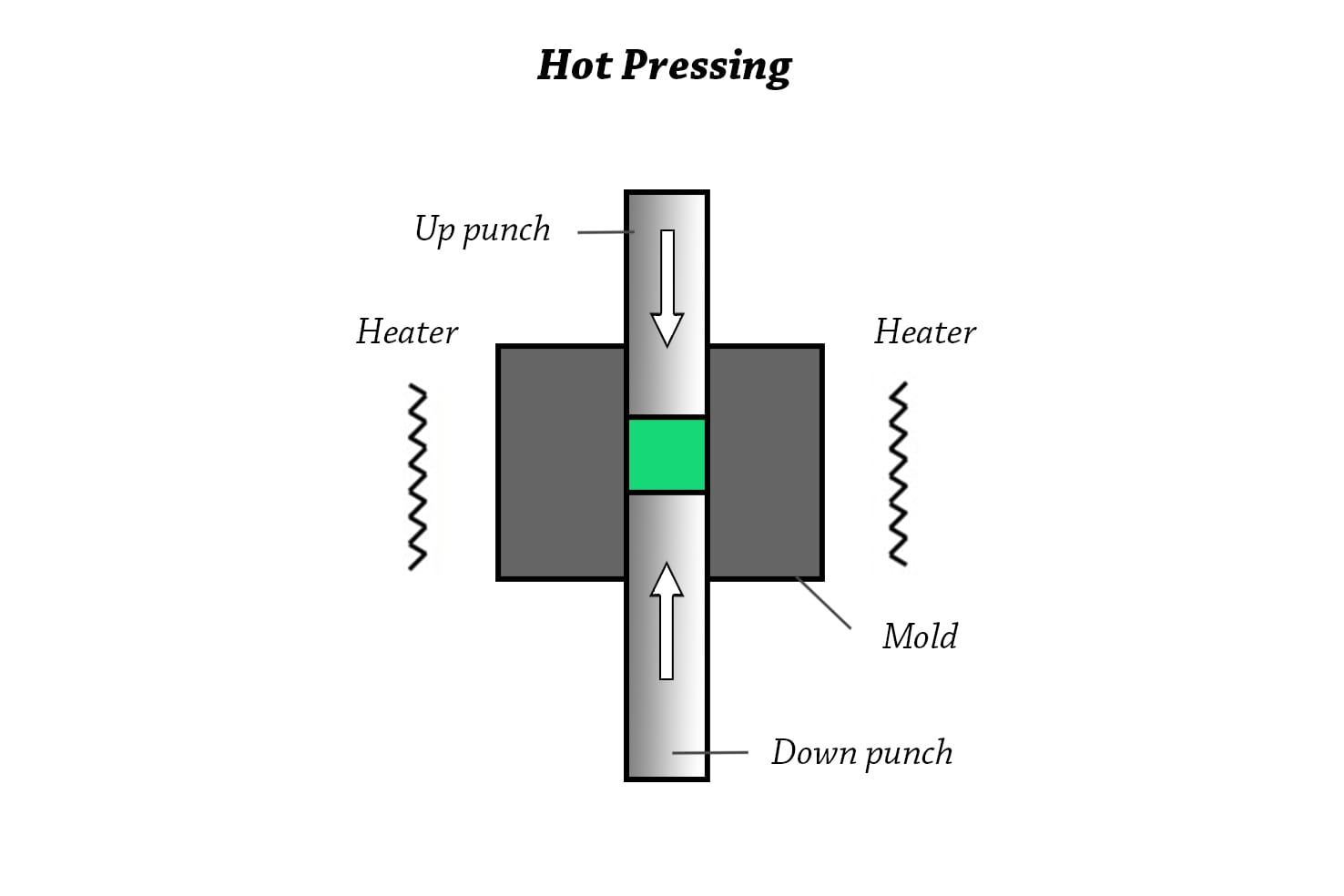

Hot pressing is a powder metallurgy process that simultaneously applies high temperature (up to 2400°C for ceramic materials) and uniaxial pressure to compact and densify powdered materials. Unlike traditional cold pressing, hot pressing combines pressing and sintering in a single step.

Contents

What is Hot Pressing?

Hot pressing is a technique in materials engineering that applies heat and pressure simultaneously for the densification and shaping of powders or composite materials. Contrary to conventional sintering techniques, which rely wholly on thermal energy, hot pressing doesn’t. Rather, it quickens the diffusion and bonding of particles under controlled pressure, which results in materials with minimal porosity and improved mechanical properties.

Hot Pressing Process

The hot pressing process basically entails applying pressure with a hot punch on the prepared powdered metal placed in a heated die under a protective atmosphere. The atmosphere is conditioned to prevent decarburization, and the oxidation of sinter goods is avoided by reducing the residual oxides.

This simultaneous application of heat and pressure results in the densification of the powdered metal or pre-compacted material. Which happens via the rearrangement of the particles and the plastic flow at their contacts.

Powder Preparation: The powdered material is prepared and placed in a mold or die.

Heating: The die is heated at a specific temperature in a conditioned atmosphere. The heating temperature is determined according to the material being processed. Typically, the hot pressing process for making ceramics operates at temperatures between 1400°C and 2000°C.

Pressing: Uniaxial pressure is applied to the compact, generally 30-50MPa.

Densification: The simultaneous application of temperature and pressure will cause the material particles to deform and sinter, thereby bonding together. This results in a dense material with less porosity.

Cooling: The resulting hot-pressed sinter is cooled to room temperature at a specific cooling rate.

Common equipment used includes, but are not limited to:

- Hydraulic Hot Presses: This equipment works with the application of high pressure and heat to materials. It is widely used in the production of plywood, particle boards, drying and leveling of veneer, shaping of decorative wood pieces, etc.

- Vacuum Hot Presses (VHP): This applies heat and pressure in a vacuum environment to sinter and bond particles. It is mostly used as a replacement for melting techniques in manufacturing high quality dense sensitive materials.

Parameters Affecting Hot Pressing

Several parameters significantly affect the quality and performance of hot-pressed materials:

Temperature

The higher the temperature, the greater the densification. The range is typically between 1000°C and 2400°C, depending on the material. However, control and precision is important in order to prevent grain growth and microstructural defects.

Pressure and Holding Time

Pressure of up to 50 MPa is needed to help deform the particles to form bonds. While the holding time ensures complete densification under peak thermal and mechanical influence.

Atmosphere

As mentioned earlier, processing in vacuum, argon, or nitrogen atmospheres helps prevent oxidation and other undesirable chemical reactions.

Die Materials

It is very important to use die materials that can withstand high temperatures, and also avoid reacting with the sample. Common die material: graphite.

Types of Hot Pressing Techniques

- Conventional Hot Pressing: This technique is used for high performance materials. Especially materials that cannot be prepared via liquid phase processing, or densified using traditional sintering and pressing methods. Suche materials include nitrides, borides, oxides, etc.

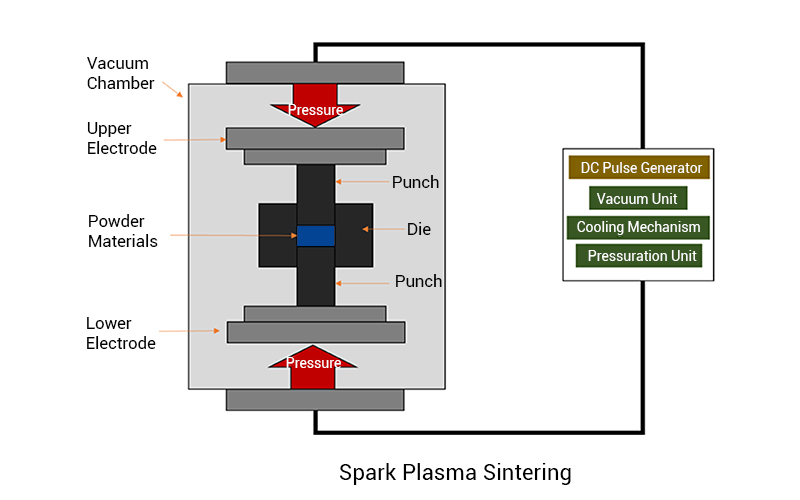

- Field Assisted Sintering Technique (FAST): This is also known as spark plasma sintering (SPS). FAST applies pulsed direct current and uniaxial pressure within a short time frame to achieve a faster densification with finer grain structures.

- Reactive Hot Pressing: In this technique, a new compound is formed when there is a chemical reaction between the starting materials. The hot press process is controlled and the chemical reaction happens slowly by solid-state diffusion. The reactants are completely converted into products because of the slow and controlled chemical process.

Hot Pressing Materials

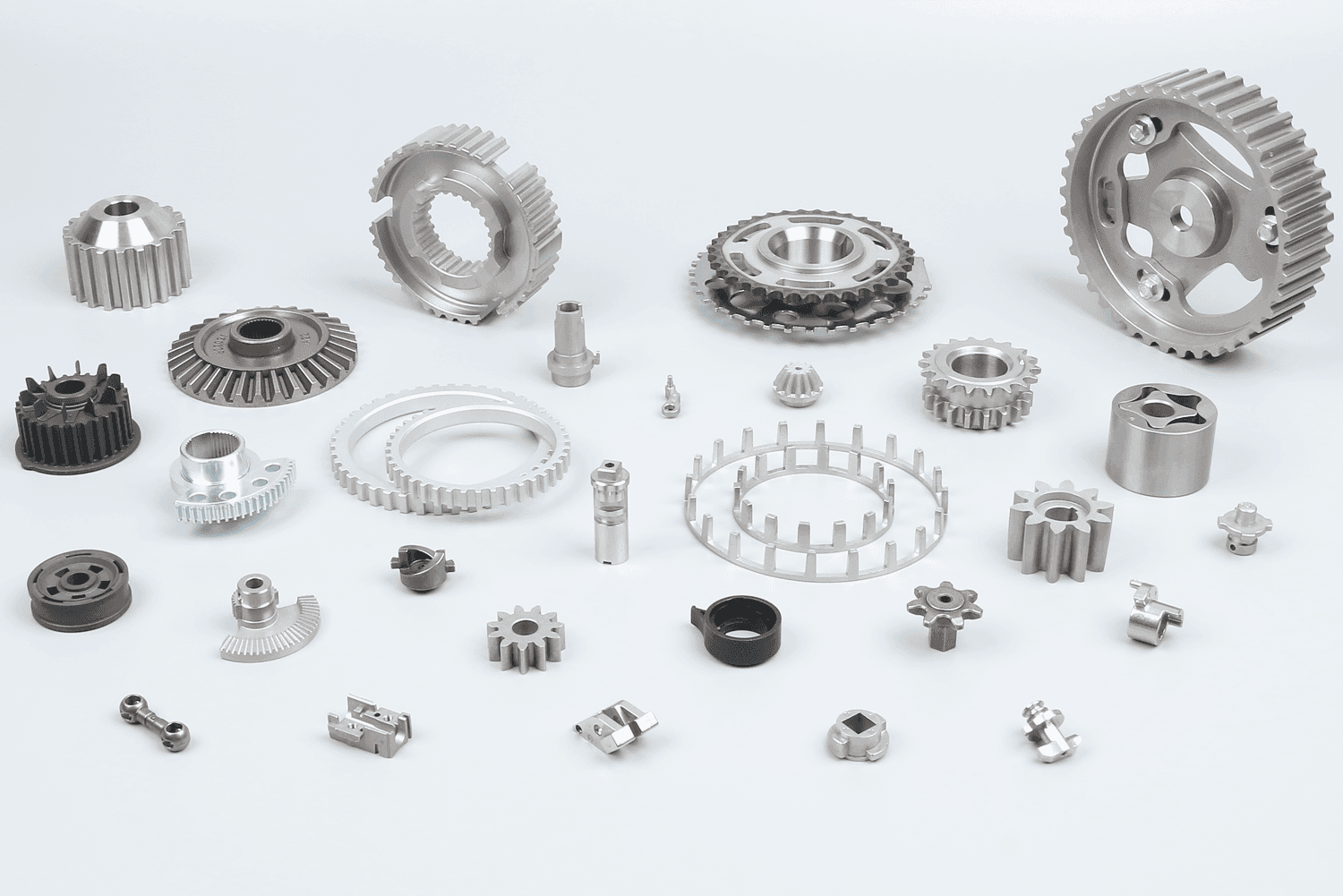

Hot pressing can process a wide range of materials that require high density and strength.

Ceramics: Alumina (Al₂O₃), silicon carbide (SiC), silicon nitride (Si₃N₄), zirconia (ZrO₂).

Metal matrix composites: Aluminum, copper, or titanium reinforced with ceramics.

Hardmetals: Tungsten carbide (WC), titanium carbide (TiC).

Applications of Hot Pressing

The uses of Hot pressing cuts across various industries:

Ceramic

The hot pressing ceramics are produced in bulk, quite dense, high in strength and hardness, with corrosion and wear resistance.

Cutting Tools

Very useful at densifying diamond-metal composites and other related materials into cutting tools.

Automotive

It is used to produce dense composites that are thermally stable and have enhanced mechanical wear resistance used for brakes, clutches, etc.

Biomaterials

This method is used to fabricate structural ceramics to ensure stability and toughness for biomedical applications e.g implants, prosthetics, etc.

Advantages and Limitations

Hot pressing can densify hard-to-sinter materials and produce parts with fine grain structure, but it is limited by the high cost of equipment.

Advantages

- Results in a high dense material with minimal porosity.

- Fine grain structure with enhanced mechanical strength.

- Can consolidate difficult-to-sinter materials (like carbides, ceramics).

Limitations

- Hot pressing typically produces parts with high density and reduced porosity, but the products cannot achieve 100% theoretical density.

- Energy consumption is high because of the high temperatures.

- High cost of equipment which is also prone to wear.

- Scalability challenges for large complex parts.

- Overall productivity is low.

Because hot pressing applies pressure in only one direction (uniaxial), uniform densification is limited, but product uniformity is improved over conventional powder metallurgy pressing.

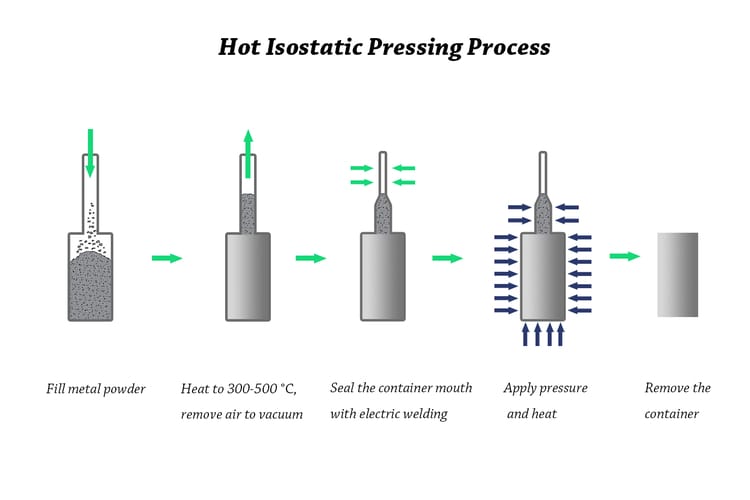

For applications that require fully dense (close to 100%) material, hot isostatic pressing (HIP) is more appropriate. HIP applies uniform pressure in all directions, enabling fully dense products.

FAQ

1. What is the Difference between Hot Pressing and Cold Pressing?

Both cold pressing and hot pressing apply uniaxial pressure to powder materials. Hot pressing uses heat and pressure for sintering and densification, while Cold Pressing uses pressure alone at room temperature, no heat.

2. What does Holding Time mean in Hot Pressing?

In hot pressing, this is defined as the duration the material is held under a specific pressure and temperature, to attain a specific goal or outcome in terms of density and strength. The duration usually ranges from a few minutes to hours.

3. Does the Cooling Rate Influence Hot Pressing?

Yes, the cooling rate can influence the resulting hot press material. It has a significant effect on the flexural, tensile, and impact strength of the material. The faster the cooling the stronger the material, but with reduced ductility.