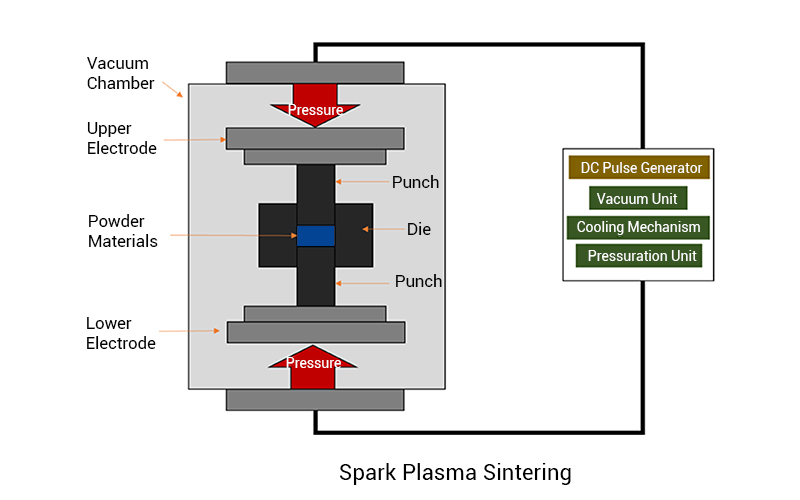

Spark Plasma Sintering (SPS), also known as Field Assisted Sintering Technology (FAST), is a modern sintering technique. This method has fundamentally changed the way powdered materials are compacted into dense solids. SPS is outstanding for not just the rapid production of dense materials, but also products with fine microstructures.

Market reports by Lucintel last year estimated the market size of SPS to hit USD1.83 billion by 2030, with a growth forecast of about 6.2% annually for 6 years, from 2024 to 2030. The Spark Plasma Sintering market plays a critical role in industries that prioritize conductivity, strength, and thermal stability. You will get to see such industries in a later section.

Contents

What is Spark Plasma Sintering?

Spark plasma sintering applies thousands to tens of thousands of amperes of pulsed direct current (DC) along with uniaxial pressure to densify powdered materials. SPS does not depend on externally introduced heat, but it generates heat internally. This process is done by passing an electric current through the material and/or the surroundings. This results in faster heating rates, quicker densification, and lower sintering temperatures.

SPS is unique due to its ability to sinter materials at higher speeds while preserving the powder’s intrinsic properties and finer grain structures. Thanks to the efficiency of this technique, coupled with the advancement in material science, there has been an increasing demand across industries.

Spark Plasma Sintering Process

The Spark Plasma Sintering process is usually done in a vacuum or an environment where the atmosphere is controlled. This is done to ensure purity and prevent oxidation. The SPS process typically entails four main stages.

Gas Removal or Vacuum Creation

First, you place the powdered material in a graphite set of a die and two punches (it serves as the heating element when current is passed through it). Gas is removed from the vacuum chamber where the die and punches are, using a rotary vacuum and diffusion pump. The air is pumped out to get a pressure of about 5-10 x 10-3 Pa.

Pressure Application.

The graphite set is subjected to uniaxial pressure, using the upper and lower electrodes. The pressure applied is up to 150 MPa and at a temperature of about 2500oC. This ensures rapid densification of the materials within a shorter time frame, minimized porosity, reduced grain growth, and the formation of a uniform structure.

Joule Heating

The direct current (DC) applied to the die is pulsed, of a low voltage, and high intensity. The Joule effect rapidly generates heat at a rate of 1000K per minute when the current passes through the die and powder. This localized heating helps facilitate rapid diffusion and particle-bonding.

Early studies believed that spark plasma sintering can quickly densify powders because of the generation of sparks or plasma between the powders. However, research has now almost confirmed that SPS heating is based on the Joule heat generated by the large resistance at the contact points between the powders. There is no spark or ion in the spark plasma sintering process, but the name has been used.

Cooling

The sinter is allowed to cool in the chamber of the SPS machine. This process controls the solidification process better and prevents the occurrence of cracks.

Materials for SPS

Spark Plasma Sintering can process a variety of materials, most especially advanced materials. Thanks to its ability to rapidly densify at relatively low temperatures and shorter time frames. Here’s a breakdown of the main types:

Ceramic

With ceramics, this technique provides fine-grain structures, Mechanical strength preservation, and enhances properties like hardness and wear resistance.

- Zirconia (ZrO₂) for dental implants and cutting tools.

- Silicon carbide (SiC) for high-temperature engine components.

- Alumina (Al₂O₃) for electronic substrates and insulating components.

Metal

Especially those difficult to process using conventional methods because of their high melting points or reactivity.

- Titanium (Ti) and its alloys for aerospace and bio-implants.

- Tungsten (W) for high-temperature applications.

- Molybdenum (Mo) for electrical and heat-resistant parts.

Composites

SPS fabricates composites with unique combinations of properties like toughness and thermal conductivity, via controlled sintering of multiple phases.

- Metal-matrix composites (e.g., aluminum reinforced with ceramic particles).

- Ceramic-matrix composites (e.g., SiC fiber-reinforced SiC matrix composites).

Advantages and Disadvantages of Spark Plasma Sintering.

SPS offers remarkable benefits, like a short time frame, energy-saving, etc. However, it has certain limitations such as scalability issues, temperature inhomogeneity, etc. Understanding these will help you evaluate their suitability for particular applications.

The benefits include:

Lower sintering temperature: SPS operates at temperatures 400–500°C lower than traditional solid-phase sintering and 100–200°C lower than hot pressing.

Fast heating rate: The heating rate can reach tens to hundreds of degrees Celsius per minute, significantly reducing thermal cycles.

Short sintering time: Sintering is completed in just 5–10 minutes, compared to several hours in conventional methods.

High sintering pressure: SPS applies pressure ranging from tens of MPa to up to 1 GPa, allowing even hard-to-sinter materials like WC and SiC to densify easily.

Microstructure control: The process allows precise control of the microstructure during sintering.

No pre-molding required: Powder can be directly compacted and sintered in one step, eliminating the need for pre-compaction.

The limitations include:

- High cost of Spark Plasma Sintering Machine and equipment maintenance.

- Managing or maintaining sintering conditions for larger scales can be very challenging.

- SPS poses a high risk of uneven microstructures because it is difficult to maintain an evenly distributed temperature within the short rise time.

Applications of SPS

SPS is widely used in various industries, like automotive, electronics, etc.

- Aerospace and Automotive Industries: These are used to make lightweight components high in strength for aircraft and vehicles.

- Electronics: Fabrication of electronic components, especially those used in high-temperature applications.

- Energy storage: Used to produce components like electrodes for solid-state battery technologies.

- Biomedical implants: Production of compatible biomaterials and surgical implants used for orthopedic and dental applications.

- Cutting tools and high-performance materials: SPS is used to produce hard tools that are resistant to wear and tear, efficient for drilling, cutting, and machining.

SPS vs Conventional Sintering

| Features | Conventional Sintering | Spark Plasma Sintering (SPS) |

|---|---|---|

| Heating Method | Uses external heating methods like furnaces. | Uses pulsed DC to generate heat internally. |

| Heating Rate | 5 to 10°C per minute (slow). | 100°C per minute (rapid). |

| Temperature Requirement | Needs a high external temperature. | Low sintering temperature needed, with about 20–30% reduction. |

| Processing Time | Takes several hours. | Takes minutes. |

| Material Properties | Significant grain growth and changes in microstructure, which could cause degraded properties. | Fine grain with minimal growth, preserves intrinsic properties and uniform structure. |

| Applications | Traditional materials like ceramics and metals, suitable for high-temperature tolerance. | Advanced materials, composites, high-precision and nanomaterials. |

Some ceramic matrix composites are difficult to densify using conventional powder metallurgy sintering due to very strong covalent bonds in their crystal structure and low self-diffusion coefficients. Spark plasma sintering (SPS) provides a new approach.

FAQ

1. What’s the Difference between SPS and Hot Pressing?

SPS is a type of hot pressing process. The biggest difference between SPS and traditional hot pressing is the heating method. SPS uses direct current to intermittently pass through the powder compaction, and hot pressing uses traditional electric heating.

2. Is Spark Plasma Sintering Suitable for Mass Production?

Yes, it is suitable for medium to mass-production scale, especially for parts that are small or medium-sized.

3. How does SPS Affect Grain Growth?

Although SPS is known for reduced grain growth due to its use of lower sintering temperatures and high pressure, it can also cause grain growth. This usually happens at the final stage of the sintering process due to stress, like high temperatures or changes in pressure cycles.