Self-Lubricating Sintered Bushings Supplier - BLUE

Discover BLUE’s extensive range of sintered bushings in a variety of sizes and shapes, including sleeve, flange, and spherical designs. Our oil-impregnated bushings are available in bronze, iron-based, and iron-copper materials, with oil content ranging from 9% to 27%.

Why Choose BLUE?

BLUE is your trusted sintered bushing manufacturer, providing high-quality oil-impregnated bushings with tight tolerances and long service life, along with free samples, fast delivery, and competitive pricing from China.

BLUE Quality Standards

BLUE assures your product quality with ISO 9001:2015 certified quality management system. We provide a one-year warranty on your sintered bearings.

Standard Parts Shop

BLUE has a wide range of standard sintered bushings in stock for quick delivery. All of these oil impregnated bushings come with no mold fees.

Download PM Product List

Discover BLUE’s full range of powder metallurgy standard powder metallurgy bearing. Download our free product list to find the exact match for your requirements.

BLUE Various Oil Impregnated Bushings in China

At BLUE, you’ll find a wide variety of standard sintered metal bushings, all available in stock. If you don’t see the exact one you need, feel free to contact us for a custom solution.

Sintered Bearing

Sintered bearing has the advantages of self-lubrication, low noise during operation and long service life.

Sintered Bronze Bearing

Sintered bronze bearing is made of CuSn10, with an oil content of 12%-25%, and is widely used in household appliances.

Sintered Iron Bushing

Sintered iron bearings are cost-effective, made of FC-0205, and have an oil content of 15%-20%.

Oil Impregnated Bushing

Oil impregnated bushings are made by pressing and sintering FC-0205, and then impregnated with oil to obtain finished product.

Impregnated Bronze Bushing

Our impregnated bronze bushing are made of FX-2005, with precise dimensional accuracy and positional accuracy.

Oil Impregnated Bronze Bushing

BLUE's Oil impregnated bronze bearings have an oil content of up to 25% and are available in a variety of sizes.

Sintered Bronze Flanged Bushings

Sintered Bronze flange bushings are self-lubricating, durable components with flange shape for easy installation.

Sintered Bronze Sleeve Bearing

Sintered bronze sleeve bearing has an oil content of 12%-22%, is made of FX-2005 and has good corrosion resistance.

Sae 841 Oil Impregnated Bronze

SAE 841 oil-impregnated bronze is a high-quality material with an oil content of 12% to 25%, made from CuSn10.

BLUE's Sintered Bushing Advantages

- High-quality management system

BLUE is ISO 9001:2015 certified and the sintered metal bearings produced are subject to strict quality control.

- Various shapes available

Whether sleeve, flanged, or spherical, BLUE has the ability to manufacture sintered bearings in a variety of sizes and shapes.

- High oil content

The oil-containing bearings produced by BLUE have good self-lubricating effect, and the oil-containing rate can reach 9%-27%, ensuring that your products can perform at their best performance.

Sintered Bushing Materials

Bronze

Sintered bronze oil-impregnated bearings have long service life, low operating noise, corrosion resistance, and are the most widely used.

Iron

Sintered iron oil impregnated bearings have the advantages of low price, excellent self-lubricating performance, fatigue resistance, and high strength. However, they have poor corrosion resistance and the lubrication effect is not as good as bronze.

Iron & Copper

Sintered bushings have good corrosion resistance and are cheaper than bronze sintered bronze bushings.

Standard Sintered Bearing

BLUE offer a multitude of oil-impregnated bushings, including sintered iron bushings, sintered bronze bushings, and sintered iron & copper bushings.

All of these standard oil-impregnated bushings are in stock and available for direct purchase.

Our sintered bronze sleeve bushings come in a range of sizes, with inner diameters from 3mm to 60mm, outer diameters from 5mm to 70mm, and lengths from 3mm to 65mm.

Free download our full list of sintered bushings by clicking below!

Working Principle of Sintered Bushings

During the operation of the sintered bushing, the lubricating oil expands from its pores under the suction of the rotating shaft and the influence of the temperature rise, forming an oil film to reduce friction.

When the oil impregnated bushing stops working, the capillary force sucks the lubricating oil back into the pores of the sintered bushing.

However, when the machine starts up, the speed is low and the lack of hydraulic pressure causes direct contact between the bearing and the shaft. This leads to increased friction, wear and temperature rise, which may cause loss of lubricating oil.

Applications of Oil Inpregnated Bushings

Oil impregnated bushings have low cost, good self-lubrication effect, low maintenance cost, and are widely used.

Automobile

Electric windows, electric seats, wiper motors, starter motors, cooling systems, brake systems, etc. in automobiles

Industry

Assembly machinery, copiers, sewing machines, automation equipment, electrical switchgear, agricultural machinery, etc.

Household appliances

Fans, coffee machines, juicers, depilators, barbecue machines, vacuum cleaners, lawn mowers, air conditioners, hand tools, etc.

Sintered Bushing Specifications

The following are the specifications of density and oil content of bronze sintered bushings, iron-based sintered bushings, iron & copper sintered bushings.

| Material | Density | Oil Content |

|---|---|---|

| Bronze Sintered Bushings | 5.8-7.6 g/cm3 | 9-27% |

| Iron-based Sintered Bushings | 5.6-6.4 g/cm3 | 17-21% |

| Iron & Copper Sintered Bushings | 5.6-6.4 g/cm3 | 17-22% |

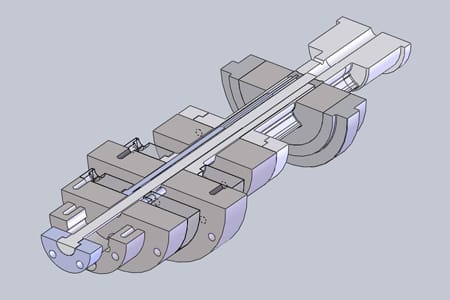

BLUE's Powder Metallurgy Products Manufacturing Equipment

As a leading sintered bushings manufacturer, BLUE is equipped with precision powder metal tooling, powder compaction presses, sintering furnaces, CNC machining equipment and advanced testing equipment.

- Compacting

- Sintering

- Inspecting

- Machining

- Packaging

Sintered Bushing Manufacturing Process

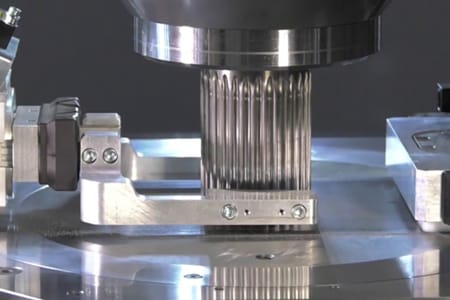

Powder metallurgy is a precision manufacturing process with a continuing and stable accuracy of up to 0.01mm, which requires strict control at each stage to ensure the quality of the final part. Any deviation or error during the process may result in the rejection of the entire batch.

Designing

Mold design is a critical process that must consider the desired part geometry, material properties, production volume, and cost-effectiveness.

Tooling

Powder metallurgy tooling includes upper and lower punches, die, and core rod. The mold needs to have excellent strength, hardness and wear resistance.

Mixing

Mixing is the process of blending metal powder with binders to improve its uniformity and fluidity, promoting better material consistency.

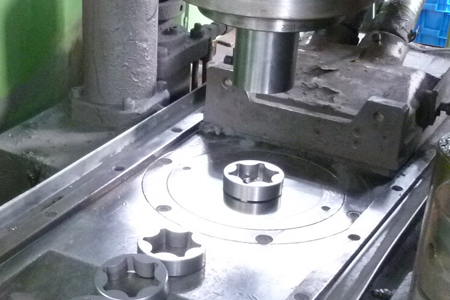

Compacting

Conpacting is a process that presses metal powder into mold cavity through powder compaction machine to get a green compact part.

Sintering

Sintering heats the green compact to a temperature below its melting point in a controlled atmosphere to obtain the desired mechanical properties.

Sizing

Sizing corrects dimensional deviations after sintering and enhances product accuracy. It requires an additional, simpler set of molds compared to the forming mold.

Tumbling

Tumbling removes burrs and flash from a part's surface by vibrating it with abrasive media, such as stone or ceramic, resulting in a smoother finish.

Machining

Machining can achieve complex shapes that cannot be pressed by powder metallurgy, such as transverse holes and screw threads.

Blackening

Blackening process, or steam treatment, forms an oxide layer to prevent rust and increase hardness, offering a cost-effective solution.

Hardening

Hardening enhances the material's strength and hardness through carburizing or nitriding, resulting in improved wear resistance and fatigue life.

Inspecting

The inspecting process is always a critical step that ensures quality and performance through BLUE inspection standards before shipping.

Packaging

BLUE's packaging process uses anti-rust paper, vacuum, blister and other methods to ensure that the product is intact during transportation.

Applications of Powder Metallurgy

BLUE’s expertise in designing and manufacturing a wide variety of powder metallurgy molds enables our customers to produce high-quality and precision powder metal parts with complex shapes and features.

Powder Metallurgy in Automotive Applications

With the advancement of technology, powder metallurgy in automotive applications is becoming more widespread. Do you know how many powder metal parts are in an

Powder Metallurgy Applications in Power Tools

Power tools make everyday work tasks a lot easier. Today, power tools are moving towards being compact, lightweight, and safe. This naturally goes hand in

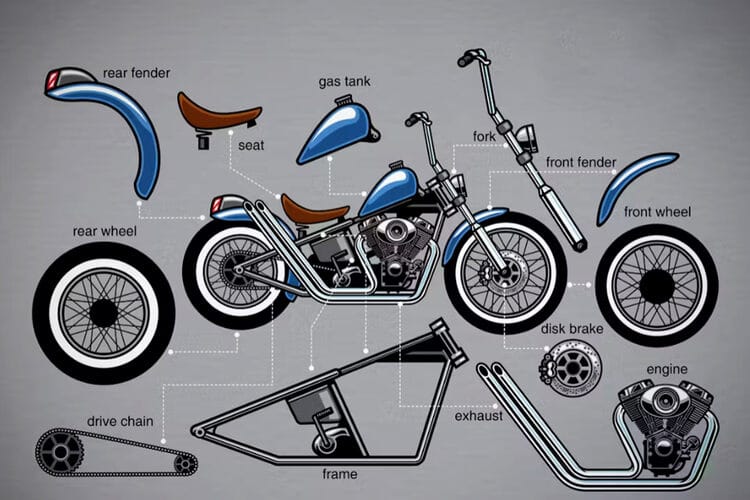

Powder Metallurgy Applications in Motorcycles

Motorcycling is closer to nature and easier to maneuver than driving. Many young people like this cool and exciting mode of transportation. Motorcycles are also

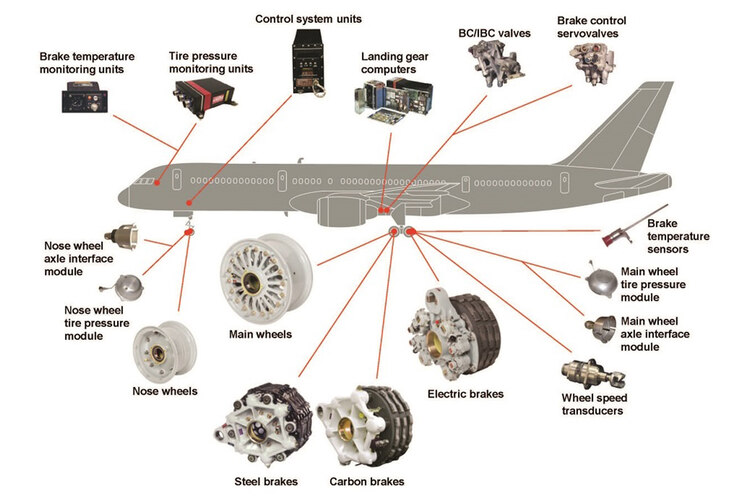

Powder Metallurgy Applications in Aerospace

You may have heard that powder metallurgy (PM) is widely applied in the mechanical industry. But do you know about powder metallurgy applications in aerospace?

Metal Injection Molding (MIM) Medical Applications

As the population ages, the health of the elderly deserves more attention. This is inseparable from advanced medical technology and equipment. It goes without saying

BLUE's Manufacturing Capabilities

BLUE not only manufactures precision sintered bushings, but also provides customized powder metallurgy parts, MIM parts, sintered filters and sintered ceramics, all of which are subject to strict quality control.

PM Tooling

BLUE has over 20 years of experience in powder metallurgy tooling design and production, with a service life of up to 500,000 cycles.

MIM Parts

BLUE's MIM parts feature flexible designs and top strength, produced with consistent quality for complex requirements.

Sintered Filters

BLUE's sintered filters are designed to resist corrosion, so it can perform reliably and durable even in harsh chemical environments.

Sintered Ceramics

BLUE's sintered ceramics offer excellent resistance to high temperatures and corrosion, along with good strength, hardness, and surface finish.

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

As we know, sintered bushings contain numerous internal pores, which makes them suitable for oil impregnation.

Typically, the bushings are placed in a mesh basket and submerged in an oil tank. A vacuum is then applied to remove air from the pores, allowing the oil to fill them.

Afterward, air is reintroduced to create atmospheric pressure, further pushing the oil into the bushing’s pores.