Powder pressing is one of the fundamental steps in powder metallurgy process. In this process, fine metal powder is compacted with the help of a mechanical or hydraulic press to get the desired green compact. The metal powder pressing process is widely adopted in many industries, such as automotive and aerospace, as it helps in the manufacturing of high-precision, near-net-shaped components. This process is considered highly efficient, as it generates minimal material waste and requires low energy consumption during mass production.

Contents

Powder Pressing Process

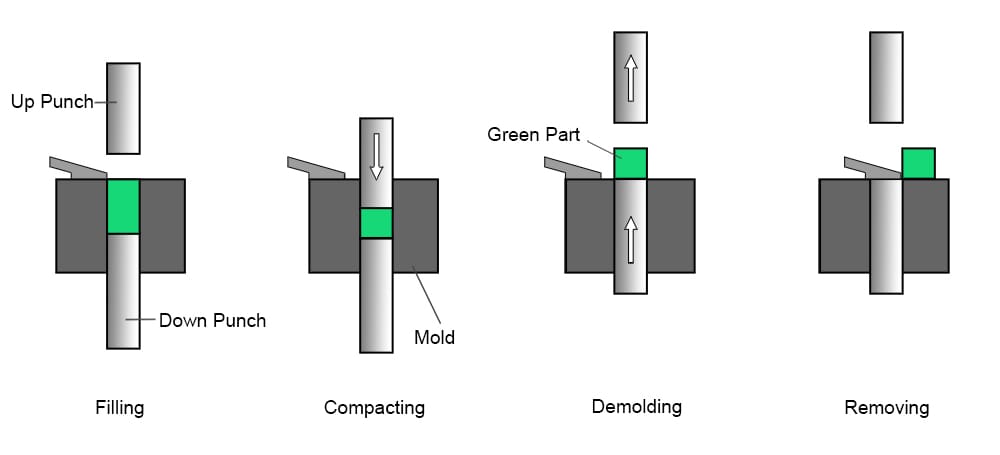

Here are the key steps for metal powder pressing process:

Filling the Die

The process of powder pressing begins by filling the metal powder into the die cavity. The filling process is carried out using an automated feed shoe, which delivers powder uniformly into the die cavity.

The rate of die filling depends on the flowability of the powder; powders with high flowability are dispersed more rapidly and uniformly.

Compaction

After the die is filled, it is now pressed with the help of punches from the top, bottom, or both sides. This powder pressing process occurs at room temperature under controlled pressure, usually ranging from 400 MPa to 800 MPa (10,000 – 120,000 psi), which is why it is also known as cold pressing. The powder metallurgy press can be either mechanical or hydraulic, as a result of which a solid green compact is formed.

The pressing forces depend upon:

- Material type, such as aluminum, requires lower force than iron.

- Particle size and morphology

- Lubrication presence

- Target green density

Ejection

As the green compact is formed now, it is carefully ejected from the die with the help of ejector pins. This step is performed carefully in order to avoid any cracks, delamination, or distortion in the green body. Now this green body is ready for sintering and further finishing process in powder metallurgy.

Types of Powder Pressing

Uniaxial Pressing

In uniaxial pressing, pressure is applied to the powder in a single direction, typically vertically, using a punch die system. This powder compaction method is used for manufacturing components with low cost, high efficiency, and simple geometries in large batches.

In the uniaxial pressing method, the powder tends to have higher density near the punch surfaces and lower density in the center of the compact. This density variation can lead to uneven shrinkage during sintering, which may affect dimensional accuracy or cause distortion.

Isostatic Pressing

You can eliminate the limitation of uneven density in the die compaction by using isostatic compaction. Here, a uniform pressure is applied to the metal powder from all directions. Isostatic pressing can be either hot or cold.

Cold Isostatic Pressing

This technique of powder pressing uses hydraulic presses at room temperature to compress metal powder uniformly. Cold isostatic pressing uses a pressure of about 34.5 MPa to 690 MPa (5,000 to 100,000 psi) to make the green body of desired density and shape. This technique is suitable for pressing powders such as metals, ceramics, plastics, and composites for large, complex components.

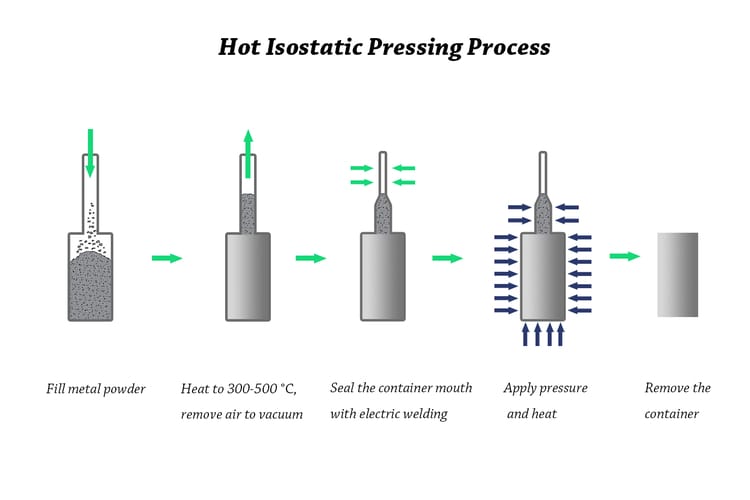

Hot Isostatic Pressing

Hot isotatic pressing is the process where the powder metals are compressed to desired shape by applying isostatic pressure of about 100–200 MPa using gas at an elevated temperature from 800 to 1350°C. The process is conducted in a sealed, high-pressure vessel lined with heat-resistant materials. You can use this pressing technique to eliminate microshrinkage, seal internal voids, and improve fatigue performance of the green body.

Warm Compaction

Warm compaction is considered one of the advanced forms of powder pressing where the powder and die are preheated before compaction. With the help of warm compaction, you can enhance the density and strength of the green compact compared to those achieved through room temperature pressing.

As the temperature rises, compaction occurs, and the powder particles deform more easily under pressure. As a result, the unfinished part obtained here has better particle bonding and reduced porosity.

Mechanism of Powder Pressing

Particle Rearrangement

In the early stage of compaction, powder particles move closer by sliding and rotating. This rearrangement fills large voids and increases packing density, without changing the shape of the particles.

Plastic Deformation

As pressure rises, particles begin to deform permanently at their contact points. This plastic deformation increases bonding areas, reduces porosity, and shapes the compact into a stronger and denser form. It is the main source of mechanical strength in the green part.

Elastic Deformation

In the final stage, most particles resist further permanent change and instead compress elastically. When the pressure is removed, the compact slightly rebounds, which can affect its size and internal stress.

Powder Pressing Tools and Equipment

Here are the main instruments used in powder pressing:

Powder Compacting Presses

Three types of presses are used here

- Mechanical presses: It is used for standard parts (up to 100 tons)

- Hydraulic presses: These presses use pressurized fluid to apply pressure. This press is used for high-force applications.

- Servo Electric Press: It uses servo motors for pressing the powder which offers precise control over speed, position, and force.

Powder Metallurgy Tooling

Powder metallurgy tooling includes the die, upper and lower punches, core pin.

Die

The die is the fixed cavity that defines the external shape of the part. It holds the powder during pressing and provides lateral support to resist expansion.

Upper Punch

Upper punch moves downward to apply pressure from the top. Its surface matches the internal top features of the part.

Lower Punch

The lower punch supports the powder from below and may move upward in single- or double-action presses. It shapes the bottom of the part and assists in ejection.

Core Pin

Core pins are used when parts require internal holes or complex internal shapes.

Benefits of Powder Pressing

Material Efficiency and Reduced Waste

Powder pressing is highly efficient as it uses over 97% of the raw material, resulting in minimal waste compared to traditional manufacturing methods like machining or casting.

Near Net-Shape Manufacturing

Components made through powder pressing typically require little to no machining after compaction. The process produces parts very close to final dimensions, reducing the need for secondary operations.

Ability to Create Complex Geometries

Another remarkable benefit of powder pressing is that it allows the formation of parts with intricate internal features, thin walls, and other complex shapes that are difficult or expensive to produce by other means.

Production of Unique Material Combinations

With the help of powder pressing, you can manufacture components with tailored properties by blending different powders.

Cost-Effectiveness for High-Volume Production

Powder pressing is well-suited for mass production due to its fast cycle times, low material waste, and minimal post-processing. This makes it ideal for industries like automotive and electronics.

BLUE is a professional powder metallurgy company in China, supplying a wide range of standard parts with no tooling fees. You can browse and compare parts directly on our SHOP page, where online selection and ordering are available. A downloadable product list is also provided for easy reference. If the part you need isn’t listed, we also support custom powder metallurgy parts based on your specifications.