Main Bearing Cap OEM & ODM Supplier

BLUE main bearing caps, also known as crankshaft bearing caps, offer excellent fatigue resistance, tensile strength, and a lightweight design. Contact us for standard engine main bearing caps with no tooling fees or customization requirements.

Why Choose BLUE?

BLUE offers high quality engine main bearing caps with good mechanical strength and tight tolerances– your trusted OEM and ODM supplier.

BLUE High Quality Standards

BLUE assure the quality of your main bearing caps with an IATF 16949: 2016 certified quality management system. Free samples are available for testing.

Standard PM Parts Shop

BLUE has a full range of standard sintered parts in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

OEM & ODM Services

With over 20 years of expertise in designing and manufacturing powder metallurgy parts, BLUE provides OEM and ODM services for you.

BLUE Main Bearing Cap in China

BLUE offers a wide range of valve seats for petrol and diesel engines, featuring low friction and resistance to high impact loads.

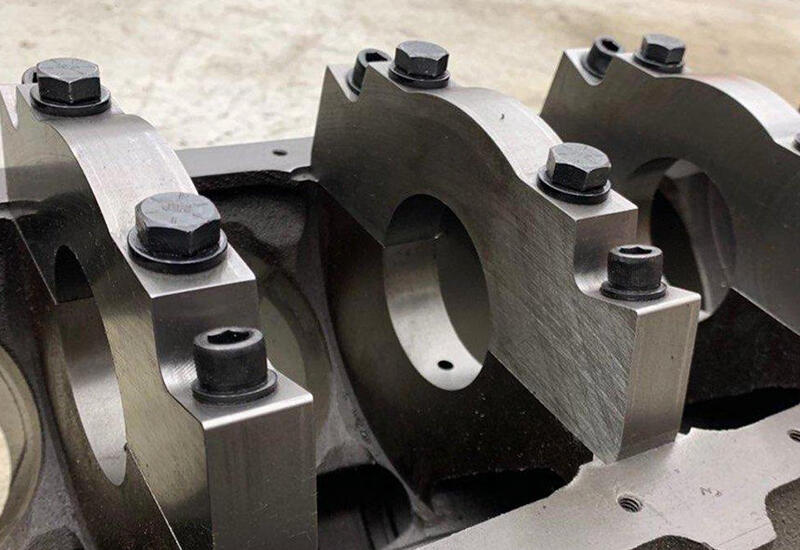

Crankshaft Bearing Cap

A crankshaft bearing cap is a part of an engine that holds the main bearing in place, supporting the crankshaft.

Engine Main Bearing Cap

BLUE intake valve seat has advantages of good lubricity, mechanical strength and corrosion resistance.

Crankshaft Main Bearing Cap

Crankshaft main bearing caps help evenly distribute engine forces and reduce wear on the main bearing.

BLUE Main Bearing Cap Features

BLUE is IATF 16949:2016 certified and has 20 years of experience in powder metallurgy design and manufacturing.

Our sintered main bearing caps feature lightweight design and excellent fatigue resistance.

BLUE’s powder metallurgy crankshaft bearing caps have an ultimate tensile strength of up to 480MP.

Our main bearing caps are precisely dimensioned to fit perfectly into the cylinder block grooves.

Standard Main Bearing Cap Supplier

BLUE is a leading powder metallurgy standard parts supplier in China, offering a wide range of standard PM parts.

Our standard sintered main bearing caps are used in many types of engines, including Toyota, Cummins, Weichai, and others.

BLUE crankshaft main bearing caps feature strict tolerances, excellent yield strength, and tensile strength.

Contact us for a free product list!

Benefits of Sintered Main Bearing Cap

Near-net shape

Sintered main bearing caps can be directly formed into their final shape through the powder metallurgy process.

Cost-effectiveness

Powder metallurgy offers a high material utilization rate and requires less secondary processing, making large-scale production very cost-effective.

Light design

Powder metallurgy main bearing caps allow for lightweight designs, reducing part weight.

What is a Crankshaft Bearing Cap?

Crankshaft bearing cap, also called main bearing cap, is an important part of the engine.

Main bearing cap supports the main bearings that support the crankshaft, ensuring smooth rotation of the crankshaft.

It distributes the load generated by engine combustion to the entire engine block, preventing damage to the crankshaft and bearings

Main bearing cap allows the crankshaft to be properly aligned and positioned in the engine block.

BLUE Custom Powder Metallurgy Parts Capabilities

The following are BLUE’s custom powder metallurgy parts capabilities, including part size, weight, wall thickness, surface roughness, etc.

| Attribute | Value |

|---|---|

| Size | Diameter 5 to 250 mm |

| Length | 5 to 200 mm. |

| Wall thickness | Minimum wall thickness is 1.5mm |

| Surface finish | Ra 0.8μm to Ra 1.6μm |

| Weight | 3 to 2000 grams |

| Tolerance | ±0.01 mm |

| Sintered Hardness | 50-70 HRB |

| Hardened Hardness | 30 HRC min |

| Material | All materials comply with MPIF 35 or DIN 30910 or JIN Z 2550 standards |

Sintered Crankshaft Bearing Cap Manufacturing Process

Powder metallurgy is a precision manufacturing process with a continuing and stable accuracy of up to 0.01mm, which requires strict control at each stage to ensure the quality of the final part. Any deviation or error during the process may result in the rejection of the entire batch.

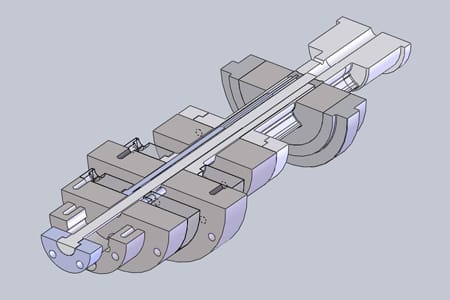

Designing

Mold design is a critical process that must consider the desired part geometry, material properties, production volume, and cost-effectiveness.

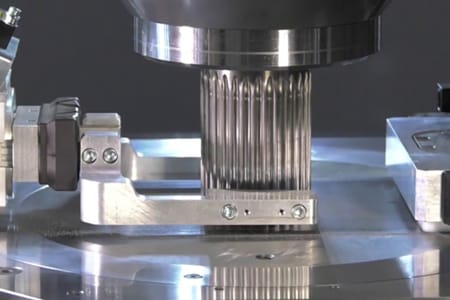

Tooling

Powder metallurgy tooling includes upper and lower punches, die, and core rod. The mold needs to have excellent strength, hardness and wear resistance.

Mixing

Mixing is the process of blending metal powder with binders to improve its uniformity and fluidity, promoting better material consistency.

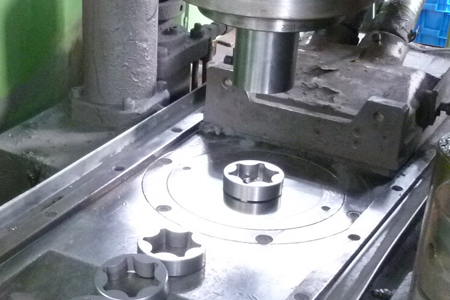

Compacting

Conpacting is a process that presses metal powder into mold cavity through powder compaction machine to get a green compact part.

Sintering

Sintering heats the green compact to a temperature below its melting point in a controlled atmosphere to obtain the desired mechanical properties.

Sizing

Sizing corrects dimensional deviations after sintering and enhances product accuracy. It requires an additional, simpler set of molds compared to the forming mold.

Tumbling

Tumbling removes burrs and flash from a part's surface by vibrating it with abrasive media, such as stone or ceramic, resulting in a smoother finish.

Machining

Machining can achieve complex shapes that cannot be pressed by powder metallurgy, such as transverse holes and screw threads.

Blackening

Blackening process, or steam treatment, forms an oxide layer to prevent rust and increase hardness, offering a cost-effective solution.

Hardening

Hardening enhances the material's strength and hardness through carburizing or nitriding, resulting in improved wear resistance and fatigue life.

Inspecting

The inspecting process is always a critical step that ensures quality and performance through BLUE inspection standards before shipping.

Packaging

BLUE's packaging process uses anti-rust paper, vacuum, blister and other methods to ensure that the product is intact during transportation.

BLUE's Powder Metallurgy Manufacturing Equipment

BLUE has a complete range of advanced powder metallurgy production equipment, including 25T to 1000T compaction press, conveyor belt sintering furnace, vacuum sintering furnace, sizing press, CNC machining equipment, hardening furnace, etc.

Related Sintered Auto Parts

As a leading supplier of powder metallurgy in China, BLUE offers a wide range of standard PM parts, including water pump pulleys, timing chain sprockets, timing belt pulleys, and oil pump rotors, all without mold fees.

Water Pump Pulley

Our water pump pulleys feature tight tolerances, high apparent density, and superior mechanical strength.

Timing Chain Sprocket

BLUE timing chain sprockets with precision teeth profile and holes, which fit perfectly with your chain and timing sprocket.

Timing Belt Pulley

Our timing pulleys are dimensionalally accurate and pair well with timing belts to smoothly transmit synchronous rotational motion.

Oil Pump Rotor

Our oil pump rotors have good surface finish, tight dimensional accuracy and excellent position tolerances to deliver optimal engine performance.