Crankshaft Sprocket OEM & ODM Supplier - BLUE

BLUE offers 500+ precision-engineered crankshaft sprockets without tooling fees. Designed for a perfect fit in timing systems, our crankshaft sprocket gears are compatible with a wide range of automobiles, including Toyota, Mazda, Honda, Land Rover, Chevrolet, Volkswagen, BMW, Audi, Peugeot, and more.

Why Choose BLUE?

BLUE provides high-quality crankshaft sprockets with tight tolerances, competitive prices, and fast delivery – your reliable OEM & ODM supplier.

BLUE High Quality Standards

BLUE assure the quality of your timing crankshaft sprockets with an IATF 16949: 2016 certified quality management system. Free samples are available for testing.

Standard Crank Sprocket Shop

BLUE has a full range of standard crank sprockets in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

OEM & ODM Services

With over 20 years of expertise in designing and manufacturing powder metallurgy parts, BLUE provides OEM and ODM services for you.

BLUE Crankshaft Sprocket in China

BLUE offers a wide range of standard sintered crankshaft sprockets with high precision, accurate tooth profiles, and good rust protection.

Timing Crankshaft Sprocket

This timing crankshaft sprocket is compatible with the Audi/Skoda/Seat vehicles equipped with 1.4 TSI and 1.6 FSI engines.

Engine Timing Crankshaft Sprocket

BLUE engine timing crankshaft sprocket has good mechanical strength and durability, specially used in toyota tacoma.

Crankshaft Sprocket Gear

BLUE crankshaft sprocket gear has a tight tolerance within ±0.015mm, applied in BMW engines.

BLUE Timing Crankshaft Sprocket Advantages

BLUE automotive powder metallurgy parts are produced under IATF 16949:2016 quality control standards.

Our crankshaft sprockets feature precision tooth profiles and holes for a perfect fit and quiet operation with the timing chain.

The surface hardness of BLUE crankshaft sprocket teeth can reach 40 HRC after hardening treatment.

We offer both standard and customized crankshaft sprockets and provide free mold design services.

Standard Crankshaft Sprocket Supplier

BLUE is a leading supplier of powder metallurgy standard parts in China, offering a wide range of timing sprockets.

Our standard crankshaft sprockets cover a variety of car and motorcycle engine models.

BLUE not only provides standard timing crankshaft sprockets, but also timing camshaft sprockets.

Download our product list for free by clicking below!

Sintered Crankft Sprocket Benefits

Cost-Effective

Compared to machining and forging, powder metallurgy offers higher material utilization, making sintered crankshaft sprockets more cost-effective.

Tight Tolerance

After sintering and the sizing process, crankshaft sprockets achieve very tight tolerances between IT 6 and IT 7.

Part-to-Part Uniformity

The production process of crankshaft sprockets is carefully controlled, assuring excellent consistency and uniformity between parts.

Material Flexibility

Powder metallurgy provides a wide range of material options to meet different application requirements.

What is a Crankshaft Sprocket?

The crankshaft sprocket is a gear part mounted on the engine crankshaft.

It connects the rotational motion of the crankshaft to the camshaft sprocket via the timing chain.

This ensures that the camshaft rotates in precise sync with the crankshaft, allowing the intake and exhaust valves to open and close at the correct intervals.

This controlled timing is important for efficient, reliable operation of the vehicle engine.

Custom Crankshaft Sprocket Specifications

The following table shows BLUE’s manufacturing capabilities for customized crankshaft sprockets, including material, density, hardness, tolerance, and surface treatment.

| Attribute | Value |

|---|---|

| Material | MPIF 35, FC-0205. FC-0208, FN-0205, FD-0208 |

| Density | 6.6-7.0g/cm3 |

| Hardness | 65-90 HRB |

| Surface Treatment | Blackening |

| Tolerance | ±0.01 mm |

Powder Metallurgy Manufacturing Process

Powder metallurgy is a precision manufacturing process with a continuing and stable accuracy of up to 0.01mm, which requires strict control at each stage to ensure the quality of the final part. Any deviation or error during the process may result in the rejection of the entire batch.

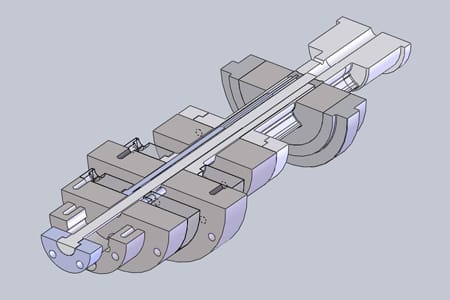

Designing

Mold design is a critical process that must consider the desired part geometry, material properties, production volume, and cost-effectiveness.

Tooling

Powder metallurgy tooling includes upper and lower punches, die, and core rod. The mold needs to have excellent strength, hardness and wear resistance.

Mixing

Mixing is the process of blending metal powder with binders to improve its uniformity and fluidity, promoting better material consistency.

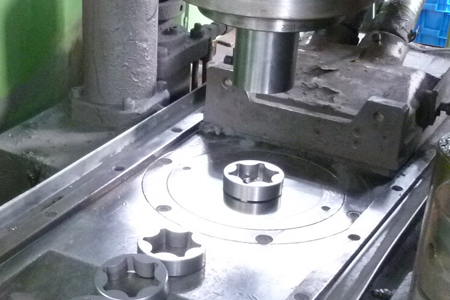

Compacting

Conpacting is a process that presses metal powder into mold cavity through powder compaction machine to get a green compact part.

Sintering

Sintering heats the green compact to a temperature below its melting point in a controlled atmosphere to obtain the desired mechanical properties.

Sizing

Sizing corrects dimensional deviations after sintering and enhances product accuracy. It requires an additional, simpler set of molds compared to the forming mold.

Tumbling

Tumbling removes burrs and flash from a part's surface by vibrating it with abrasive media, such as stone or ceramic, resulting in a smoother finish.

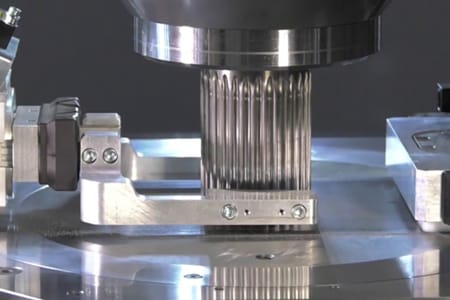

Machining

Machining can achieve complex shapes that cannot be pressed by powder metallurgy, such as transverse holes and screw threads.

Blackening

Blackening process, or steam treatment, forms an oxide layer to prevent rust and increase hardness, offering a cost-effective solution.

Hardening

Hardening enhances the material's strength and hardness through carburizing or nitriding, resulting in improved wear resistance and fatigue life.

Inspecting

The inspecting process is always a critical step that ensures quality and performance through BLUE inspection standards before shipping.

Packaging

BLUE's packaging process uses anti-rust paper, vacuum, blister and other methods to ensure that the product is intact during transportation.

BLUE's Powder Metallurgy Manufacturing Equipment

BLUE has a complete range of advanced powder metallurgy production equipment, including 25T to 1000T compaction press, conveyor belt sintering furnace, vacuum sintering furnace, sizing press, CNC machining equipment, hardening furnace, etc.

Related Powder Metallurgy Auto Parts

As a leading supplier of powder metallurgy in China, BLUE offers a wide range of standard PM parts without mold fees.

Water Pump Pulley

Our water pump pulleys feature tight tolerances, high apparent density, and superior mechanical strength.

Timing Chain Sprocket

BLUE timing chain sprockets with precision teeth profile and holes, which fit perfectly with your chain and timing sprocket.

Timing Belt Pulley

Our timing pulleys are dimensionalally accurate and pair well with timing belts to smoothly transmit synchronous rotational motion.

Oil Pump Rotor

Our oil pump rotors have good surface finish, tight dimensional accuracy and excellent position tolerances to deliver optimal engine performance.

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

A bad crankshaft sprocket can lead to several engine issues. Common symptoms include:

Engine Misfires: If the sprocket isn’t syncing the timing chain properly, the valves and pistons may misalign, causing misfires.

Unusual Noises: Worn or damaged sprockets can create knocking, rattling, or other strange sounds, especially at higher speeds.

Vibration: A damaged sprocket can cause excessive engine vibration, which may be felt throughout the vehicle.