Compressor Valve Plate Manufacturer - BLUE

BLUE supplies high-quality compressor valve plates with excellent corrosion resistance and tight tolerances, suitable for various household refrigerators and refrigeration equipment. Our standard air compressor plates come with no mold fees.

Why Choose BLUE?

BLUE delivers top-quality compressor valve plate backed by a robust quality control system. We also offer free mold design services and free samples.

BLUE High Quality Standards

BLUE guarantee the quality of your PM compressor valve plates with ISO 9001: 2015 certified quality management system. Free samples are available for testing.

Standard Parts Shop

BLUE has a full range of standard parts in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications

Free Mold Design Service

With over 20 years of expertise, BLUE provides free, high-precision mold design services tailored to your needs. Trust our experience to deliver for you!

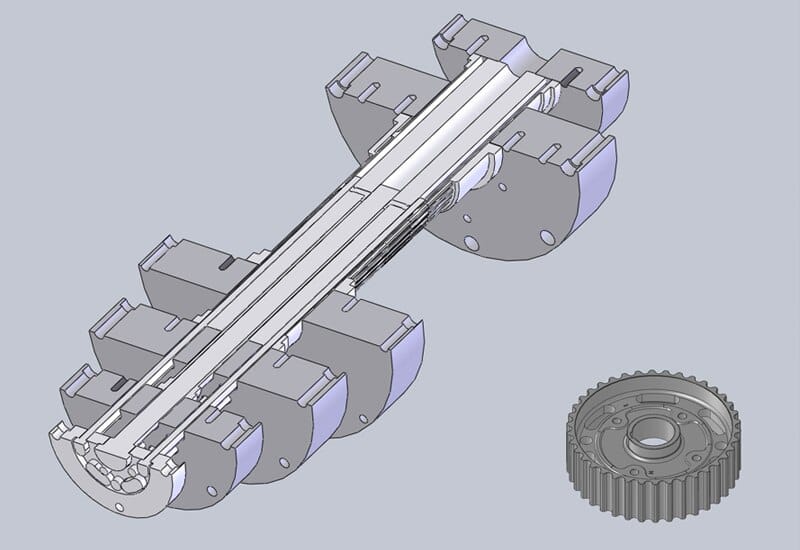

What is Compressor Valve Plate?

A compressor valve plate is a key element in a reciprocating air compressor, positioned between the cylinder and the head to direct airflow through the compression cycle.

It contains the intake and discharge valves, which open and close in response to pressure changes, allowing air to enter the cylinder during the intake stroke and exit during compression. By regulating this one-way flow, the valve plate ensures stable compression, proper sealing, and overall system efficiency.

Valve plates are commonly made from high-strength steel or P/M materials because they must withstand high pressures, repeated cycling, and temperature fluctuations. Precision and wear resistance are critical, as defects or wear in the valve plate can cause loss of compression, overheating, or reduced performance.

Powder Metallurgy Process for Compressor Valve Plates

A compressor valve plate made by powder metallurgy is formed by compacting metal powders in a precision die. This creates the plate shape, valve openings, and sealing surfaces in a near-net-shape form. The green compact is then sintered at high temperature to give it the needed strength, stability, and wear resistance.

After sintering, several finishing steps are used to improve accuracy. Common steps include sizing, CNC machining of valve seats or holes, and surface grinding or lapping to achieve good flatness. Steam treatment can also be added to increase air-tightness, hardness, and overall strength.

Sintered compressor valve plates are widely used because they offer high strength, consistent quality, and cost-effective production. They can also maintain reliable sealing and withstand repeated pressure and temperature cycles.

Applications of Compressor Valve Plates

Compressor valve plates are used in reciprocating compressors for industrial air systems, refrigeration units, and general manufacturing equipment. They regulate one-way gas flow and help keep compression stable.

They are also used in petrochemical plants, natural-gas pipelines, and oil-and-gas compressors. These applications often involve high pressure, high cycling, and gases that may be dirty or corrosive.

To handle these conditions, compressor valve plates are made from high-strength steel, powder-metallurgy alloys, or polymers like PEEK. These materials improve sealing, reduce wear, and extend compressor life.

Advantages of Sintered Compressor Valve Plates?

Powder metal compressor valve plates are wildy used due to:Powder metal compressor valve plates have the following advantages:

Cost-effectiveness

Compared with machining, the powder metallurgy process requires fewer steps and consumes less energy, making it more cost-effective for large-scale production.

Part to part consistency

Powder metallurgy compressor valve plates have high quality consistency from batch to batch

Precision manufacturing

PM can produce valve plates in near-net shape, thus reducing subsequent machining.

Steam Treatment for Compressor Valve Plate

Steam treatment, also known blackening, exposes sintered iron parts to high-temperature steam, forming a Fe₃O₄ oxide layer on the surface.

This process seals the holes of compressor valve plates, improving air tightness and allowing them to withstand gas pressures of 1.5-3.0 MPa without leakage.

In addition, blackening enhances the valve plate’s hardness and corrosion resistance.

BLUE Compressor Valve Plate Advantages

BLUE is an ISO 9001: 2015 certified company with the ability to manufacture high quality compression valve plates.

Our sintered compressor valve plates have high mechanical strength and good durability.

Our sintered compressor valve plates have a sintering density of more than 6.7g/cm³ and excellent wear resistance.

The compressor valve plates produced by BLUE are blackened and have good rust resistance.

Air Compressor Valve Plate in China

Our air compressor valve plate has tight tolerances, fine surface finish, good durability and corrosion resistance.

Air Compressor Valve Plate

BLUE's powder metallurgy compressor valve plate has been blackened, with good corrosion resistance and wear resistance.

Sintered Compressor Valve Plate

Our sintered compressor valve plate uses high-quality iron-based metal powder as raw material, which has high quality consistency and good strength after sintering.

Air Compressor Plate

Our air compressor valve plates provide a reliable seal to ensure efficient refrigeration operation.