Types of Powder Metallurgy Process

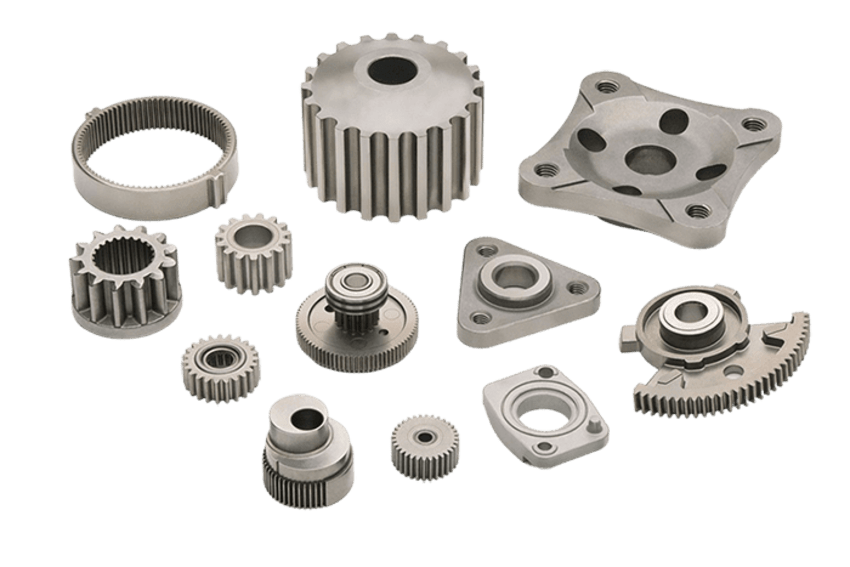

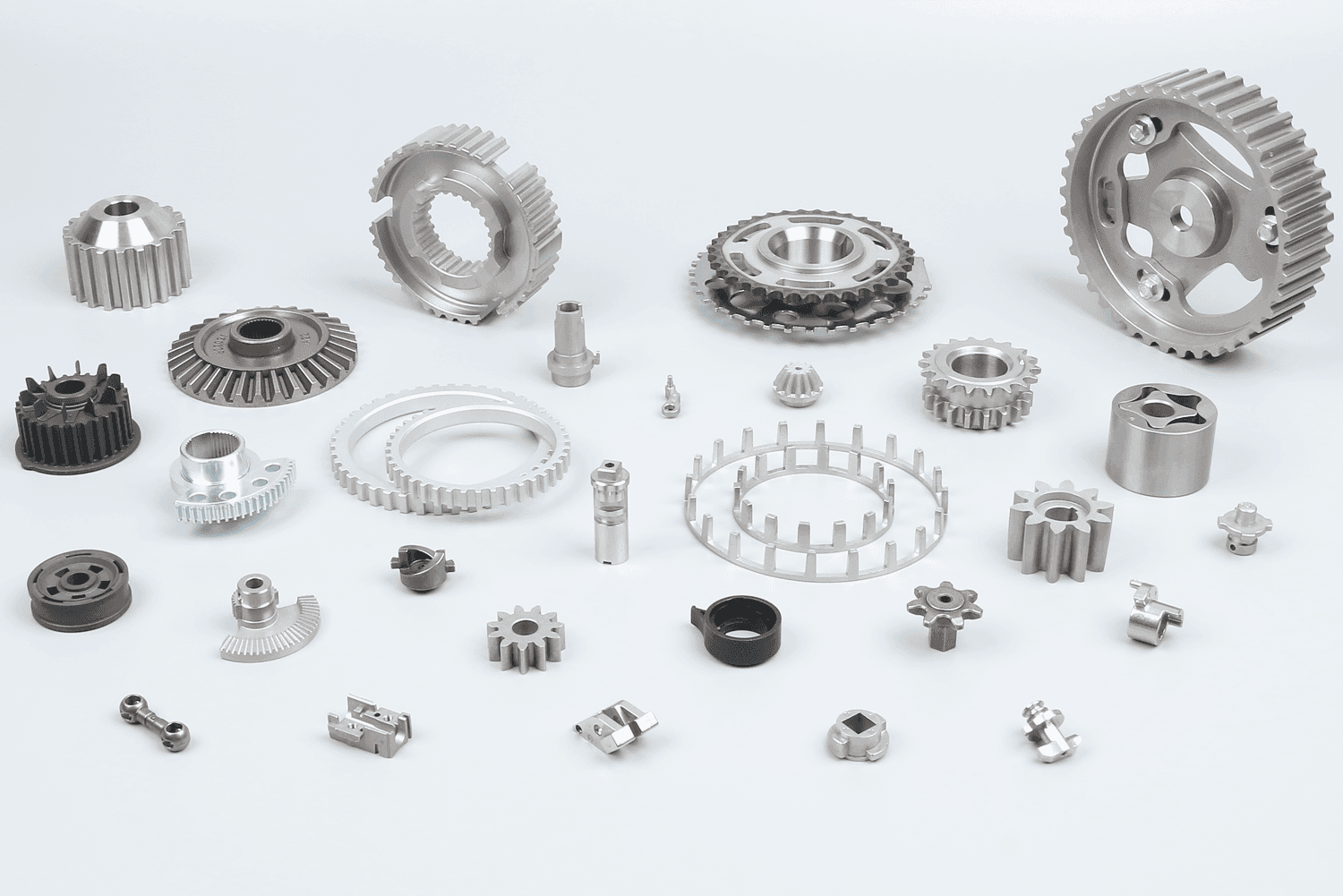

It is well known that powder metallurgy (PM) is an advanced manufacturing technique. PM forms parts from metal powder, offering high material utilization and fast production speeds. Today, different types of powder metallurgy processes are applied in automotive, motorcycle, medical, and aerospace industries. Let’s take