What is Sinter Hardening?

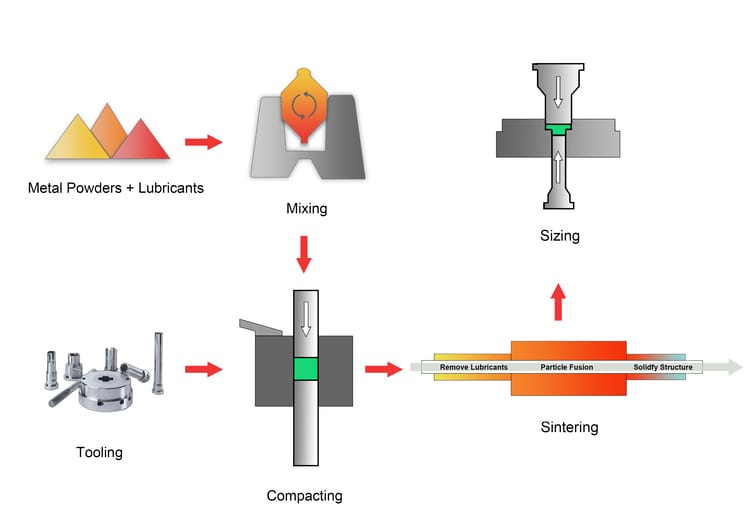

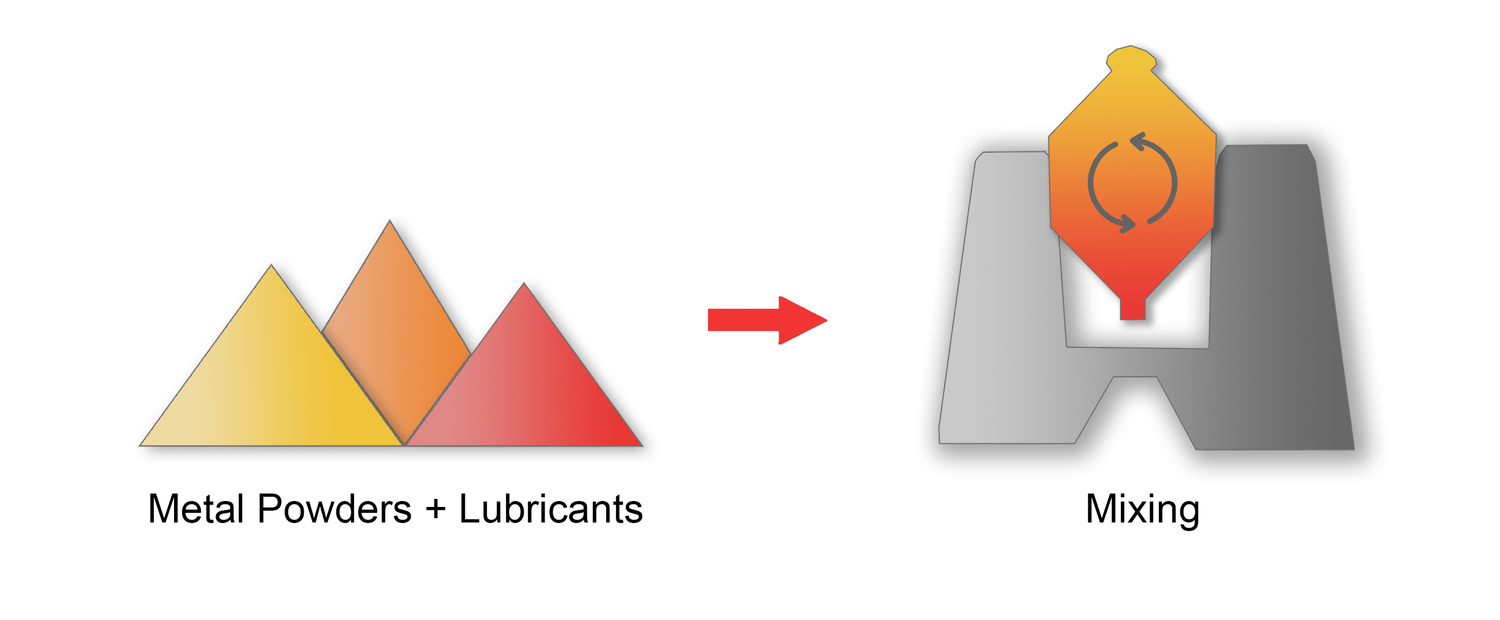

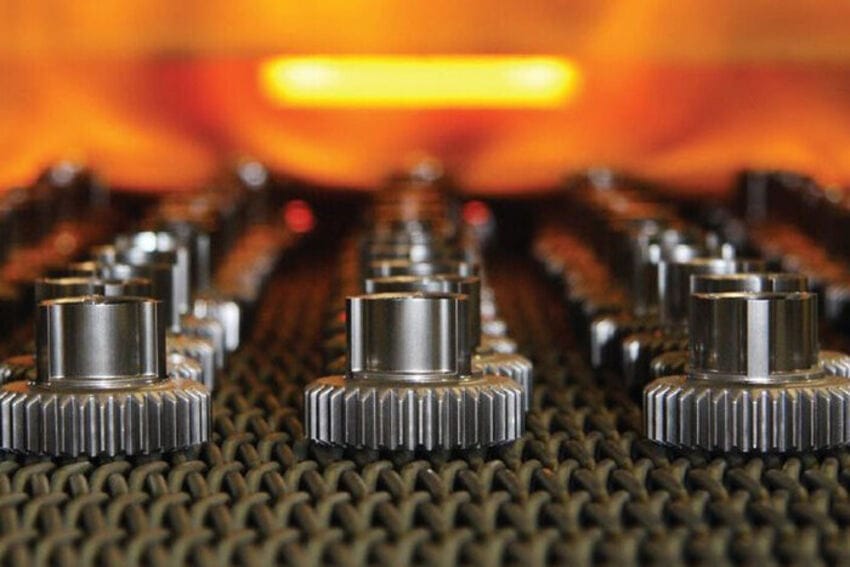

Sinter hardening is an advanced powder metallurgy (PM) process that integrates conventional sintering with in-furnace hardening in a single continuous cycle. During this process, compacted alloy powders are sintered at high temperature under a controlled atmosphere. Instead of slow cooling, the parts undergo accelerated gas