Sinter hardening is an advanced powder metallurgy (PM) process that integrates conventional sintering with in-furnace hardening in a single continuous cycle. During this process, compacted alloy powders are sintered at high temperature under a controlled atmosphere. Instead of slow cooling, the parts undergo accelerated gas cooling inside the furnace, promoting the formation of a martensitic microstructure.

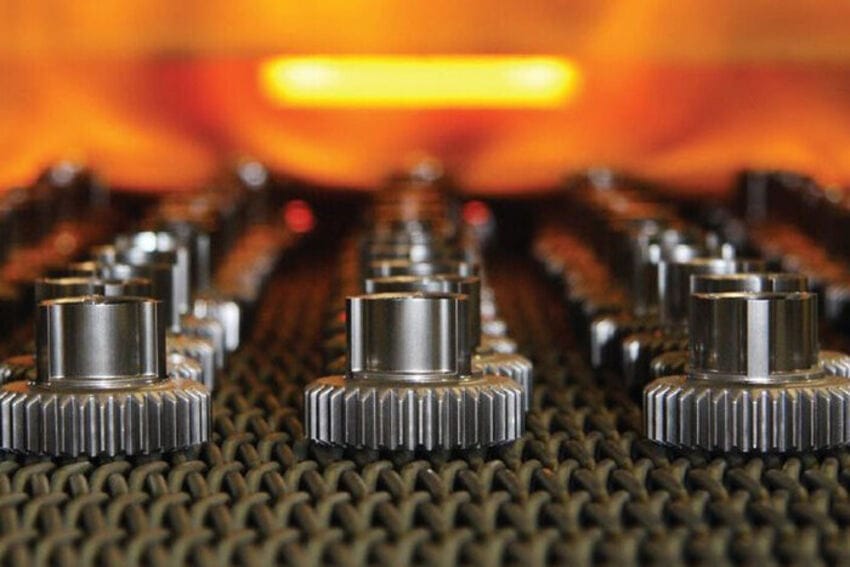

This approach often eliminates the need for a separate quench-and-temper step, reducing distortion and shortening the production cycle. The result is powder metal components with improved hardness, strength, and dimensional stability, making sinter hardening particularly suitable for automotive gears, sprockets, and other high-performance applications.

Contents

Sinter Hardening Process

Powder Compaction

Metal powder is compacted in a rigid die under high pressure through uniaxial pressing. This compacting process increases the relative density of the compact and produces a green compact with sufficient handling strength. Although near-net-shape geometry is achieved, the green compact still exhibits low mechanical strength and requires sintering for metallurgical bonding.

Sintering at High Temperature

Then, the green compacts are sintered in continuous mesh-belt or pusher furnaces under a controlled protective atmosphere. At approximately 70–90% of the metal’s melting temperature, solid-state diffusion promotes metallurgical bonding between particles. During this stage, lubricants are volatilized, and a reducing atmosphere assists in minimizing surface oxides.

Accelerated Cooling

Instead of conventional slow cooling, sinter hardening employs accelerated gas cooling within the furnace. High-velocity nitrogen–hydrogen mixtures or dissociated ammonia circulate through the hot zone, producing rapid quenching rates that transform the microstructure to martensite. This step imparts high hardness and strength, and in many cases eliminates the need for a separate oil quench. Tempering may still be applied when improved toughness is required.

Sintering Atmosphere

The inert atmosphere inside the furnace plays a key role in protecting the compacted parts from oxidation. If the components face oxygen contamination during high-temperature exposure, it can severely degrade bonding, surface finish, and final strength. That is why an oxygen-free environment is maintained by gases such as nitrogen or argon to ensure clean metallic surfaces throughout the thermal cycle. In addition to preventing oxidation, the furnace gas composition can actively reduce oxides already present on the powder.

Advantages of Sinter Hardening

Cost Savings

Sintered hardening is comparatively cost-effective than the traditional PM process as it eliminates a separate quench-and-temper cycle and reduces furnace usage, labor, and energy consumption. Fewer process steps result directly in lower production costs, especially for high-volume components.

Cleaner Surface

Components obtained through sinter hardening technology pose a cleaner surface because parts are gas-quenched rather than oil-quenched. Due to this, the surface remains free of retained quench media, facilitating post-processing operations such as plating, coating, or machining.

Improved Mechanical Properties

Accelerated cooling promotes the formation of a martensitic microstructure, though uniformity depends on alloy hardenability and part geometry.

Shorter Lead Time

Combining sintering and hardening into a single step accelerates the production cycle. Powder metal parts obtained here are ready for use or secondary operations more quickly, improving throughput for high-volume manufacturing.

Energy Efficiency

Sinter hardening includes fewer furnace cycles and the absence of oil quenching, which results in a cut of overall energy use. Another factor that makes it energy efficient is the use of gas-impingement for rapid cooling, which is more efficient than traditional reheating and liquid quenching.

Limitations of Sinter Hardening

Sinter hardening shows some limitations that must be considered before utilizing this process, such as the process requires specialized sintering furnaces capable of accelerated gas quenching, which can increase initial capital investment. All material grades do not respond equally to accelerated cooling, like low hardenability powders may not achieve the desired martensitic structure. Lastly, the method offers limited flexibility for parts requiring extreme dimensional variations or post-sinter modifications.

Applications of Sinter Hardening

Automotive Compound Gears

Sinter hardening is applied to compound gears in autonotive transmissions. The process forms martensite during sintering, avoids oil quenching, reduces distortion, and maintains AGMA-level dimensional control.

Transfer Case Sprockets

In off-highway vehicles, sinter hardening is used for transfer case sprockets. It shortens the process from four to two steps and delivers strength comparable to quenched parts.

Power Tool Gears

High-speed and high-torque gears in electric power tools are manufactured with sinter hardening. Using sinter hardened powders, the process produces a martensitic structure with hardness up to about 37 HRC and stable dimensions.

Sinter Hardening vs. Conventional Hardening

Here is table illustrating the difference between sinter hardening and traditional PM hardening:

| Feature | Conventional PM Hardening | Sinter Hardening |

|---|---|---|

| Process Steps | Compaction → Sintering → Reheating → Oil Quench → Tempering | Compaction → Sintering with in-furnace accelerated cooling (tempering may still be applied) |

| Hardness and Strength | Martensite achieved by quenching after reheating | Martensite develops during furnace cooling of hardenable alloys |

| Dimensional Control | Risk of distortion from reheating and oil quench | Improved stability due to elimination of separate quench, though final accuracy still depends on sizing |

| Energy Consumption | Multiple furnace cycles, higher overall use | Fewer cycles, lower overall consumption despite cooling system load |

| Surface Condition | Oil residues require cleaning | Gas quenching leaves a cleaner surface |

| Process Time & Labor | Longer cycle, more handling steps | Shorter cycle with fewer steps |

| Application | General PM parts where post-sinter hardening acceptable | High-volume gears, sprockets, cams, housings with hardenable alloys and suitable geometry |

| Cost Efficiency | Higher total cost in large volumes | More cost-effective in high-volume production, though furnaces are higher capital cost |

BLUE is your reliable powder metallurgy manufacturer, offering both sinter-hardening and conventional sintering with heat treatment. Explore thousands of standard parts with no tooling cost in our online shop, or request customized services for your projects.