Sintered Water Pump Pulley Supplier

BLUE offers 500+ standard sintered water pump pulleys without mold charges, compatible with various engine models and belt types. Our pulleys have the advantages of high density, good mechanical strength and tight tolerance.

Why Choose BLUE?

BLUE is your dependable supplier of water pump pulleys, offering free mold design service, free samples, fast shipping, and competitive prices.

BLUE High Quality Standards

BLUE assurethe quality of your water pump pulleys with an ISO 9001:2015 certified quality management system. Free samples are available for testing.

Standard Water Pump Pulley Shop

BLUE has a full range of standard pulleys in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

Free Mold Design Service

With over 20 years of expertise in mold design, BLUE offers free, high-precision mold design services to meet your customized needs. Let our experience work for you!

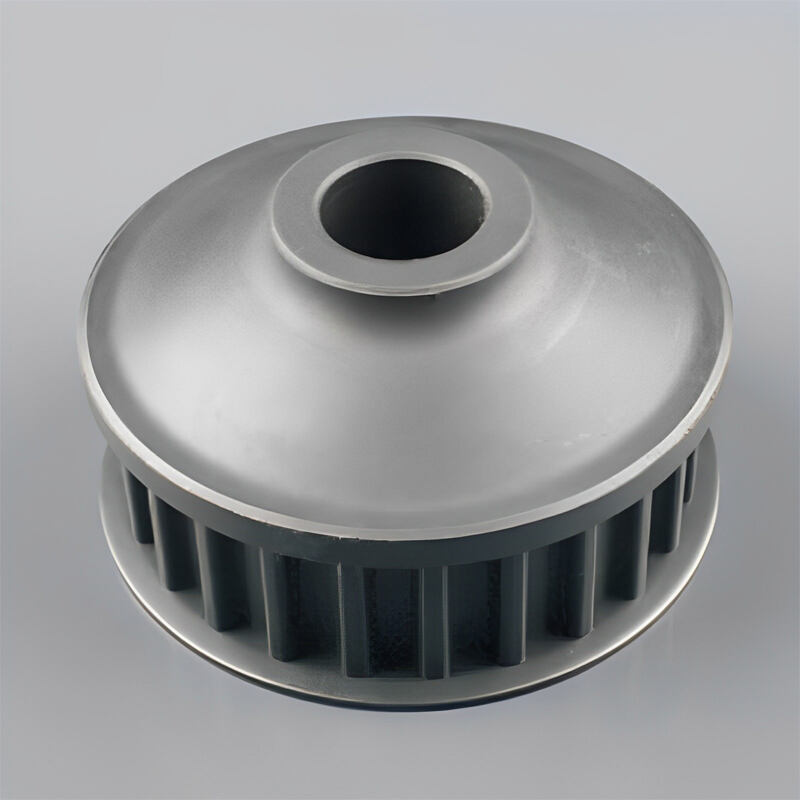

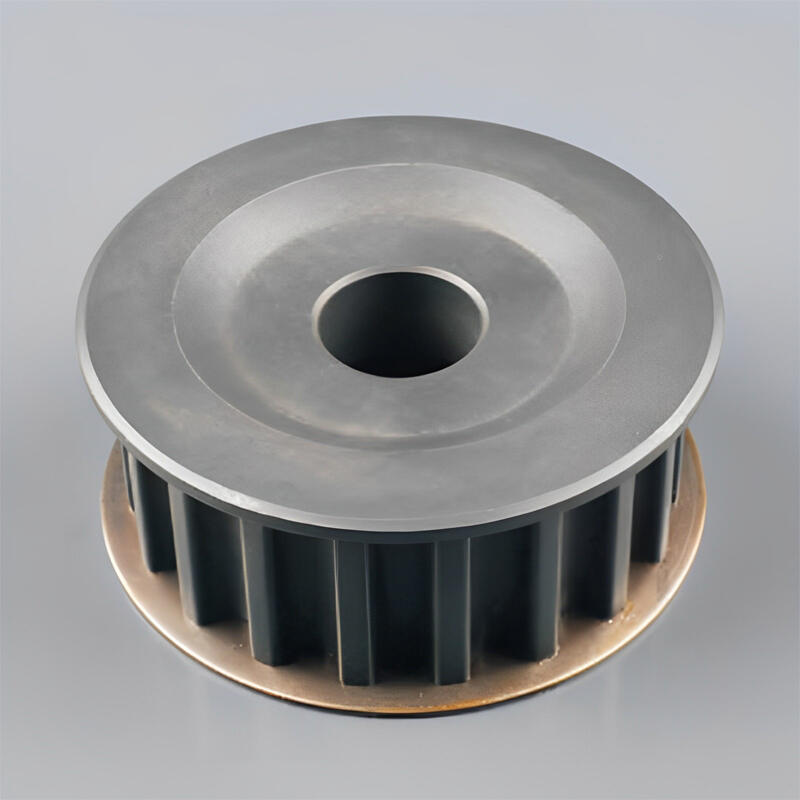

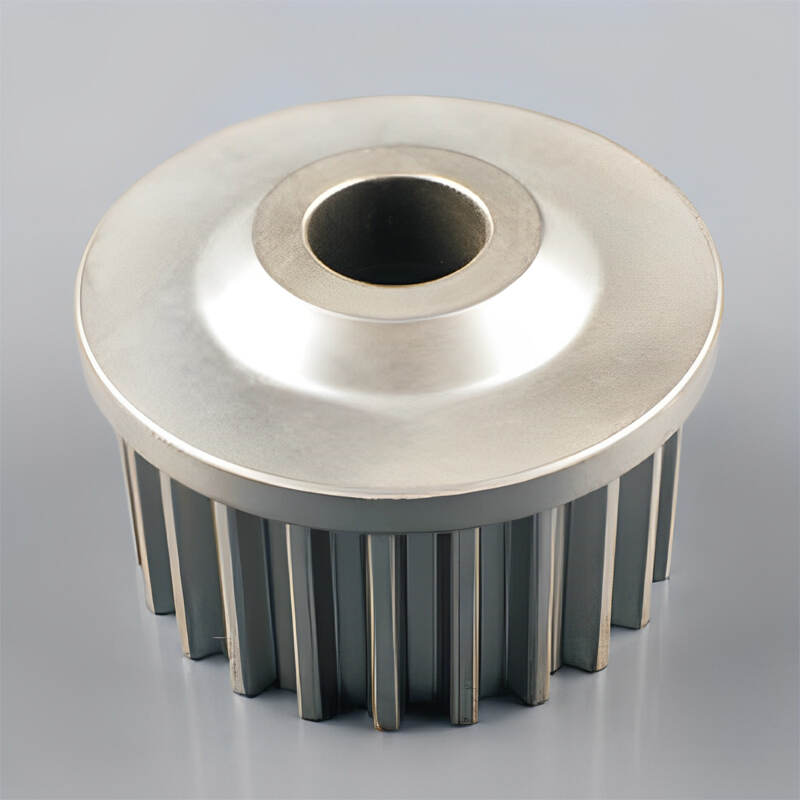

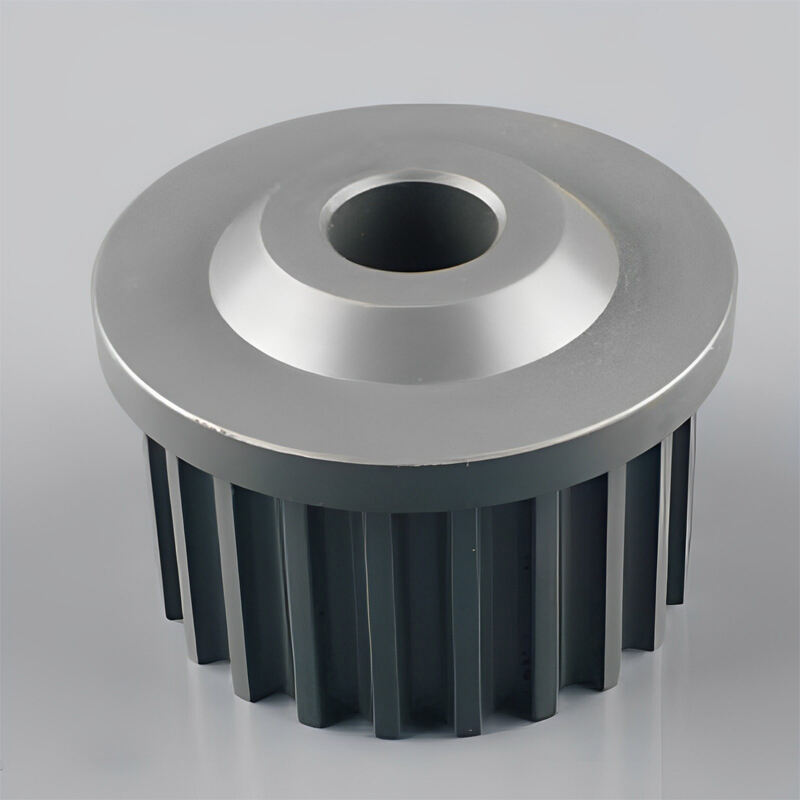

BLUE Powder Metallurgy Water Pump Pulley

BLUE offers you a broad selection of sintered water pump pulleys with good mechanical strength and corrosion resistance

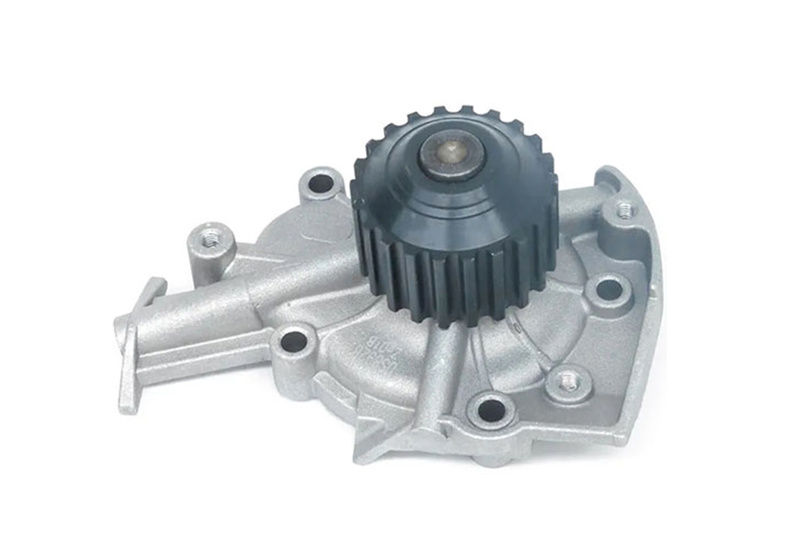

Car Water Pump Pulley

BLUE car water pump pulley drives the water pump, which circulates coolant through the engine and radiator, preventing the engine from overheating.

Short Water Pump Pulley

BLUE short water pump pulley is suitable for small cylinder engine and compact water pump.

Mini Water Pump Pulley

BLUE mini water pump pulleys offer an ideal choice for engines requiring a more compact water pump.

351w Water Pump Pulley

Our 351W water pump pulley features a reliable structure and is specifically designed for the Ford 351 Windsor engine.

SBC Water Pump Pulley

Our SBC water pump pulleys have tight dimensional tolerances, good mechanical properties and long service life.

318 Pulley Water Pump

BLUE 318 water pump pulleys feature high tooth profile precision and a good fit with the belt, allowing smooth transmission of engine power to the water pump.

2JZ Water Pump Pulley

BLUE 2JZ water pump pulley has close tolerances and operates smoothly, ensuring the pump circulates coolant.

440 Water Pump Pulley

440 water pump pulley is connected to the engine crankshaft through a belt to provide power for the water pump

1JZ Water Pump Pulley

Our 1JZ water pump pulley is used in 1JZ engine, with durability and excellent performance.

What is a Water Pump Pulley?

A water pump pulley is a precision-machined drive component mounted on the water pump shaft that transmits rotational torque from the engine’s serpentine belt to the water pump impeller. By converting belt motion into pump rotation, it maintains continuous coolant circulation through the engine block and radiator, which stabilizes operating temperature and prevents thermal failure.

In automotive and industrial powertrain systems, the pulley must maintain accurate concentricity, proper belt alignment, and stable rotational speed to ensure efficient coolant flow. A worn or damaged pulley can cause belt slip, pump under-speed, or vibration, leading to insufficient coolant delivery and potential engine overheating.

Advantages of Powder Metal Water Pump Pulleys

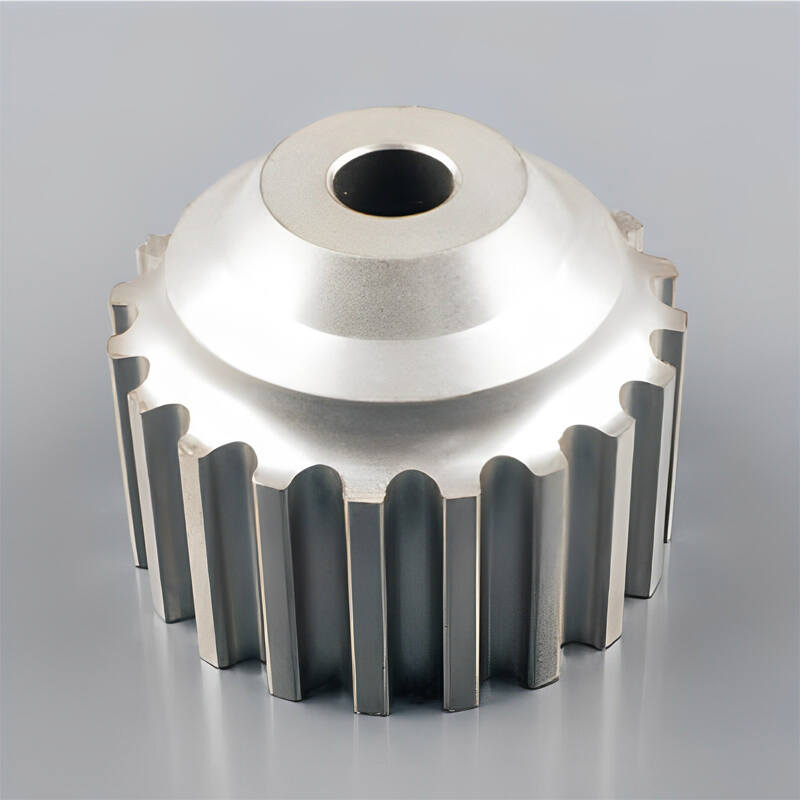

Water pump pulleys can be manufactured using the powder metallurgy (PM) process, where iron-based powders are compacted into a precise die cavity and sintered to form a strong, dimensionally stable component. This near-net-shape forming allows the pulley’s hub, flange geometry, and belt contact surface to be produced with high accuracy, minimizing subsequent machining.

Through controlled sintering and optional secondary operations—such as sizing, steam treatment, resin/oil impregnation, or surface hardening—PM pulleys achieve the concentricity, balance, and mechanical strength required for high-speed rotation in automotive cooling systems. The uniform microstructure and optimized alloy design enable reliable torque transmission from the serpentine belt to the water pump impeller.

Compared with stamped or fully machined pulleys, PM pulleys provide excellent dimensional repeatability, lower material waste, and competitive cost in medium-to-high volume production. This makes powder metallurgy a practical and widely adopted solution for manufacturing compact, lightweight, and durable water pump pulleys.

BLUE Water Pump Pulley Advantages

BLUE powder metallurgy parts are manufactured in compliance with IATF 16949:2016 standards.

Our water pump pulleys are available in a variety of auto models, including A4 1.8T, A6 1.8T, and CC 2.0 TSI, offering a broad selection to meet your needs.

Our pulleys have precise tooth profiles, which can smoothly transmit engine power and ensure the normal operation of the water pump.

BLUE sintered pulleys are surface-treated with options like Dacromet and galvanization, offering good corrosion resistance.

Standard Water Pump Pulleys

With over 20 years of expertise in powder metallurgy manufacturing, we are a professional supplier offering a range of standard parts for quick mass production.

Our wide selection of standard water pump pulleys is designed to fit various automotive engine models, including TFSI, TFI, HDI, TDI, DCI, etc.

Download our free product list to find the perfect match for your needs.

PM Water Pump Pulley Benefits

Less Material Waste

sintered pulleys are compacted from metal powder, ensuring high material utilization with minimal waste.

Tight Tolerance

The precision of powder metallurgy molds and the sizing process allow sintered water pump pulleys to achieve dimensional tolerances within ±0.02 mm.

High Design Flexibility

Powder metallurgy enables the production of pulleys with complex shapes and intricate features.

Consistent Quality

Powder metallurgy pulleys maintain exceptional quality consistency across batches due to the precise control of powder metallurgy process.

How Water Pump Pulley Works?

Water pump pulley operates by being connected to the engine crankshaft via a belt, which moves it as the engine runs, transferring rotational energy.

This rotation powers the internal impeller of the water pump, which circulates coolant through the engine and radiator to regulate temperature.

By controlling the speed of the water pump, the pulley ensures the cooling system operates efficiently, preventing overheating during operation.

Custom Water Pump Pulley Specifications

The following table shows BLUE’s production capabilities for water pump pulleys, including density, hardness, tolerance and diameter range, surface treatment, etc.

| Attribute | Value |

|---|---|

| Material | MPIF 35 FC-0205. FC-0208, FN-0205, FD-0208 |

| Density | 6.6-7.0g/cm3 |

| Hardness | 65-90 HRB |

| Surface Treatment | Blackening, Dacromet, Electroplating |

| Diameter | No more than 250mm |

| Length | No more than 200mm |

| Tolerance | ±0.015 mm |

Powder Metallurgy Manufacturing Process

Powder metallurgy is a precision manufacturing process with a continuing and stable accuracy of up to 0.01mm, which requires strict control at each stage to ensure the quality of the final part. Any deviation or error during the process may result in the rejection of the entire batch.

Designing

Mold design is a critical process that must consider the desired part geometry, material properties, production volume, and cost-effectiveness.

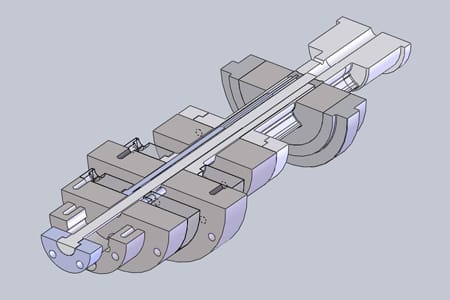

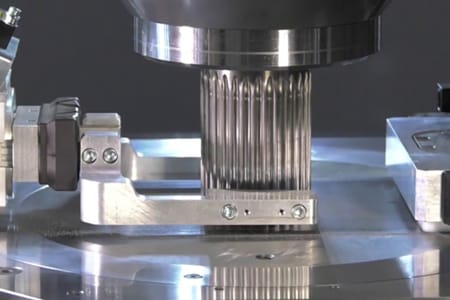

Tooling

Powder metallurgy tooling includes upper and lower punches, die, and core rod. The mold needs to have excellent strength, hardness and wear resistance.

Mixing

Mixing is the process of blending metal powder with binders to improve its uniformity and fluidity, promoting better material consistency.

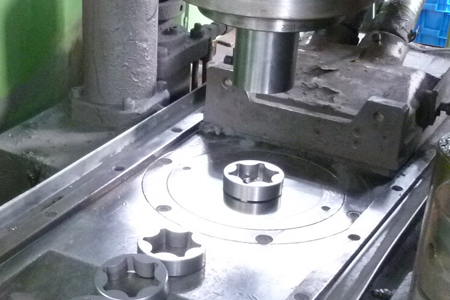

Compacting

Conpacting is a process that presses metal powder into mold cavity through powder compaction machine to get a green compact part.

Sintering

Sintering heats the green compact to a temperature below its melting point in a controlled atmosphere to obtain the desired mechanical properties.

Sizing

Sizing corrects dimensional deviations after sintering and enhances product accuracy. It requires an additional, simpler set of molds compared to the forming mold.

Tumbling

Tumbling removes burrs and flash from a part's surface by vibrating it with abrasive media, such as stone or ceramic, resulting in a smoother finish.

Machining

Machining can achieve complex shapes that cannot be pressed by powder metallurgy, such as transverse holes and screw threads.

Blackening

Blackening process, or steam treatment, forms an oxide layer to prevent rust and increase hardness, offering a cost-effective solution.

Hardening

Hardening enhances the material's strength and hardness through carburizing or nitriding, resulting in improved wear resistance and fatigue life.

Inspecting

The inspecting process is always a critical step that ensures quality and performance through BLUE inspection standards before shipping.

Packaging

BLUE's packaging process uses anti-rust paper, vacuum, blister and other methods to ensure that the product is intact during transportation.

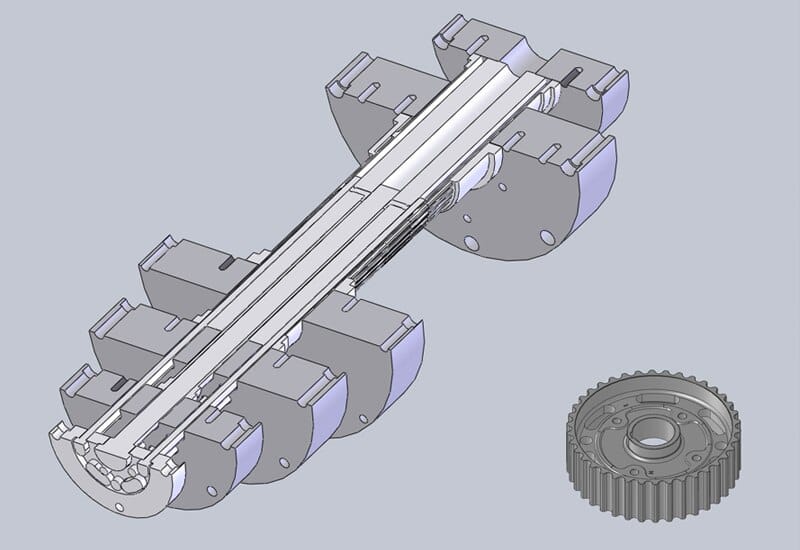

Equipment for Water Pump Pulley

BLUE has a complete range of advanced powder metallurgy production equipment, including 25T to 1000T compaction press, conveyor belt sintering furnace, vacuum sintering furnace, sizing press, CNC machining equipment, Machine Center, hardening furnace, etc.

Related Product

As the largest supplier of powder metallurgy standard parts in China, BLUE offers a wide range of standard auto parts with no mold fees.

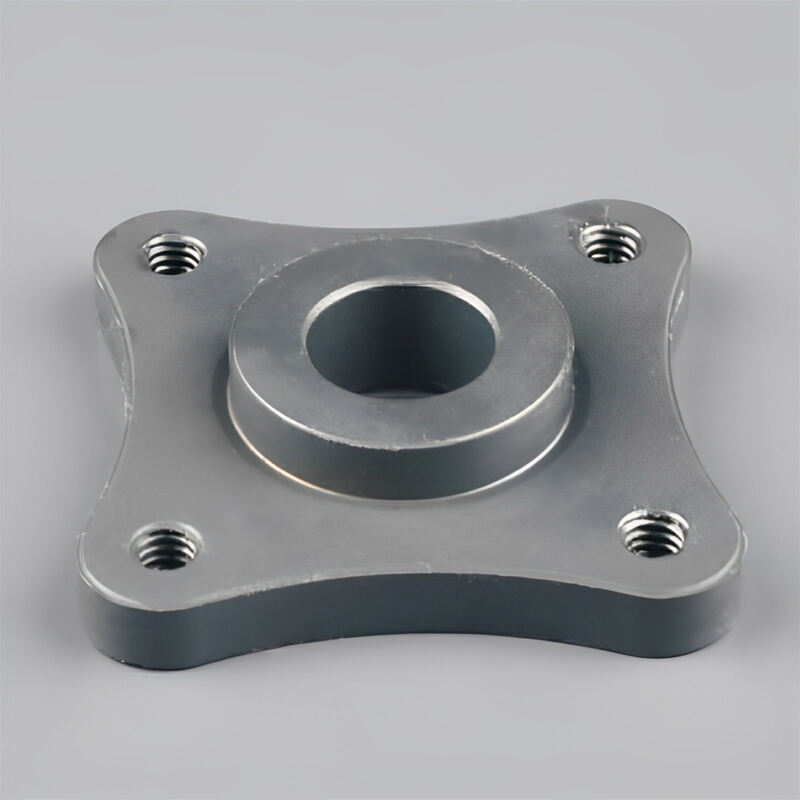

Water Pump Flange

Our pump flanges have the advantages of multiple models, tight tolerances and high mechanical strength.

Timing Belt Pulley

Our timing pulleys are dimensionalally accurate and pair well with timing belts to smoothly transmit synchronous rotational motion.

Oil Pump Rotor

Our oil pump rotors have good surface finish, tight dimensional accuracy and excellent position tolerances to deliver optimal engine performance.