Gears are round mechanical parts with teeth around their edges. When two or more gears mesh together, they transfer motion and torque between rotating shafts. By changing the direction, speed, or force of movement, gears play a important role in many machines and devices. Sintered gears and machined gears are two common types used by engineers in various industries.

In this article, you’ll learn how these two types of gears are made, their strengths and weaknesses, and how they compare in cost, precision, durability, and performance.

Contents

What Are Sintered Gears?

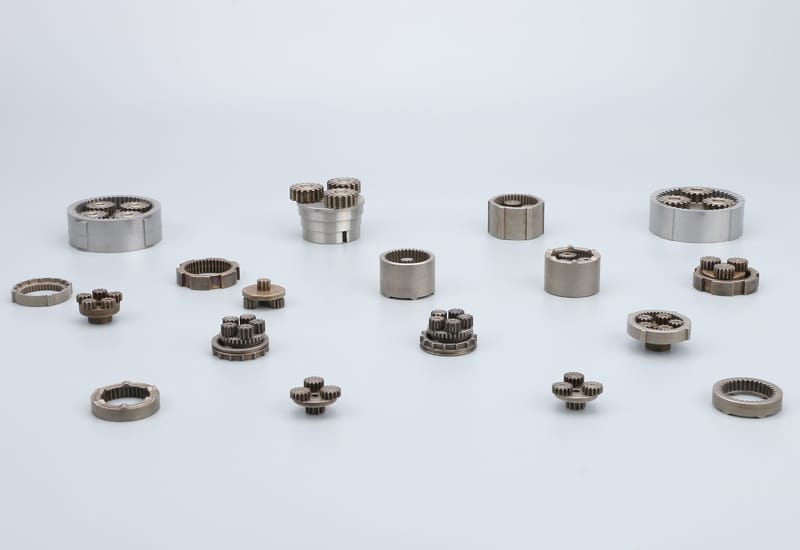

Sintered gears are precision components produced through the powder metallurgy process. Unlike conventional gears that are machined from solid metal blanks, sintered gears are formed directly from metal powders. Powder metallurgy process has the ability to precise control over the gear’s geometry, porosity, and material properties.

How are Sintered Gears Made?

Sintered gears are manufactured using metal powder in the following way:

Mixing

The process starts with the blending of metal powders, typically iron or iron-based alloys, with binders such as zinc stearate or lithium stearate. These binders help improve powder flow, increase bulk density, enhance compressibility, and reduce the force required to eject the compacted part from the die.

Compaction

Then, the metal powder is compacted (typically pressure 400 to 800 MPa) into a die to form a green compact of the desired gear shape. At the compacting process, the density of powder increases, and the required geometry and shape are achieved by applying controlled pressure.

Sintering

The green compact is then placed in a sintering furnace and heated in a controlled atmosphere. For iron-based materials, the typical sintering temperature ranges from 1120°C to 1150°C. During sinteirng process, solid-state diffusion occurs, bonding the metal particles together and increasing the part’s strength and structural integrity.

Secondary Processes

Optional secondary processes such as sizing process, heat tereatment or oil impregnation can be applied to further improve strength, wear resistance, and performance. Sintered gears are widely used in automotive, electronics, and other industries that demand reliable, precision components.

What Are Machined Gears?

Machined gears are the components formed by removing material from a solid gear blank with the help of mechanical processes, such as milling, hobbing, or shaping. By using these methods, one can accurately control the tooth profile and gear size, making them accurate. Usually, steel or alloy pre-manufactured blanks are used for the production of machined gears.

How are Machined Gears Made?

The manufacturing process of machined gears is roughly as follows:

Gear Blank Preparation

Machine gears are typically manufactured from solid metal stocks or forged blanks. These blanks are manufactured from various materials, including steel and aluminum, which are then cut to the desired shape and size to create a gear blank.

Gear Cutting

Now the gear blank is subjected to cutting to get the desired geometry of teeth. This is done by using different cutting techniques, such as milling, hobbing, or shaping. Each tooth is cut into the metal using CNC machines or other precision tools.

Finishing Operations

Finally, the gear undergoes finishing steps depending upon its applications. Here, the gears’ surface finish, hardness, and dimensional precision are improved either by heat treatment or grinding.

Sintered vs Machined Gears: Key Differences

Dimensional Tolerances

When it comes to dimensional tolerance, the machined gears excel over sintered gears due to their manufacturing process. Since sintered gears are manufactured by heating the metal powder, they exhibit inherent porosity with 10-20% void and thermal shrinkage. This porosity and shrinkage cause the low dimensional tolerance.

However, the machined gears are manufactured through cutting and grinding, such as CNC machining. Gears manufactured with CNC machining can achieve a dimensional tolerance of ±0.005 mm.

Surface Finish

Machined gears are considered to show a better surface finish with a lower Ra (Roughness average) of about 0.6 μm compared to sintered gears with a Ra value of about 0.8-1.6 μm. This is basically due to the precision of CNC machining and grinding operations. In CNC machining, material is removed in a controlled manner, producing smoother tooth profiles and tighter surface roughness control.

Strength and Load Capacity

For strength and load capacity, sintered gears are considered effective for lower loads due to their less dense structure. Sintered gears exhibit lower contact fatigue and impact resistance due to their porosity. Whereas, the higher density of machined gears enables them to handle high loads more effectively, due to their excellent fatigue resistance and structural integrity.

Cost Considerations

Sintered gears are usually cost-effective, especially in large-scale production, compared to machined gears. This is due to the minimal or no material wastage during the manufacturing process. This can be estimated from the scrap waste percentage of both methods, as PM has only 3-5% scrap waste, whereas the waste of machining can be as high as 40-60%. Not only this, sintered gears may not require any secondary operation for finishing, which also contributes to their lower production cost compared to machined gears.

Time of Production

Sintered gears can be manufactured in less time, especially for complex designs and large production volumes, compared to machined gears. This is due to the slow and prolonged machining process, which requires multiple steps compared to powder metallurgy.

Self-Lubrication Capabilities

The porous nature of sintered gears enables them to exhibit self-lubrication through oil impregnation during manufacturing. In sintered gears, lubricants are drawn into the pores via vacuum impregnation and gradually released under operational heat. Self-lubrication is not a property of machined gears; they require external lubrication for proper operation.

Design Flexibility

Since the Sintered gears are manufactured through PM, it allows for the creation of intricate geometries right from the start, instead of subtracting material from a solid block as in traditional machining. Due to this, sintered gears have an edge when it comes to design flexibility over the machined gears. Not only does this PM allow for creative and complex designs that might be too difficult or expensive to achieve using CNC machining.

Advantages and Disadvantages

Pros and Cons of Sintered Gears

Pros:

- Cost-effective for large-scale production due to efficient batch processing

- Minimal material waste due to the additive powder metallurgy process

- Capable of forming complex geometries like helical gears

- Good part-to-part repeatability for high-volume production

- Controlled porosity can enable self-lubricating properties

- Near-net-shape forming reduces or eliminates the need for secondary machining

Cons:

- Lower dimensional precision compared to machined gears

- Inherent porosity reduces strength unless densification is applied

- Limited ability to form complex internal features

- Surface finish may be rougher and often requires post-processing

Pros and Cons of Machined Gears

Pros:

- High dimensional precision and tight tolerances

- Excellent surface finish directly from the machining process

- Allows intricate and customized features like threads and cross-holes

- Suitable for a wide range of materials without sintering constraints

Cons:

- More energy-intensive with longer production times per part

- High tool wear when machining hard metals, increasing tool costs

- Limited efficiency for highly complex or internal geometries without advanced tooling

BLUE is an ISO 9001:2015 certified powder metallurgy supplier trusted for precision and reliability.

We offer a comprehensive selection of sintered gears, including spur, helical, and bevel types. Our SHOP features a wide range of standard powder metal gears ready for immediate use. If you don’t see the exact gear you need, we also provide custom service to match your specific requirements.