When you enter the powder metallurgy (PM) industry, it is advisable to refer to the PM standards to achieve the desired product performance. These standards specify the chemical composition, mechanical properties, and physical properties of various PM materials, providing valuable guidance for engineers in the design and manufacture of powder metallurgy parts.

You may be familiar with the MPIF 35 standard, which is the most widely used in the United States and globally. Additionally, Germany’s DIN 30910 and Japan’s JIS Z 2550 are also commonly referenced.

Contents

MPIF Standard 35

MPIF 35 Standards are published by the Metal Powder Industries Federation. They provide detailed information on powder metallurgy materials for materials engineers and powder metallurgy practitioners.

MPIF hopes to promote the development and application of powder metallurgy materials and technologies.

It specifies the acceptable ranges of chemical elements in PM materials.

It also defines the minimum mechanical properties (such as tensile strength, yield strength, and hardness) that PM parts must achieve after sintering.

The MPIF Standard consists of the following four parts:

Materials Standards for PM Structural Parts

Examples of PM Material Designation Coding.

| Materials | Nominal Compositions | Complete Code for Material |

|---|---|---|

| PM Bronze | Cu-90%, Sn-10% | CT-1000-13 |

| PM Brass | Cu-90%, Zn-10% | CZ-1000-11 |

| PM Iron | Fe, 99%, C-0.2% | F-0000-20 |

| PM Steel | Fe, 98%, C-0.8% | F-0008-35 |

| PM Copper Steel | Fe, 96%, Cu-2%, C-0.8% | FC-0208-60 |

| PM Nickel Steel | Fe, 96%, Ni-2%, C-0.5% | FN-0205-35 |

| PM Infiltrated Iron | Fe, 78%, Cu-20% | FX-2000-25 |

| PM Stainless Steel (austenitic) | AISI 316 (modified) | SS-316N1-25 |

PM Iron

Unalloyed PM Iron (F-0000) is often used in lightly loaded structural applications such as ABS sensor rings. It is also used for self-lubricating structural parts where strength is not important.

Here are some common PM iron materials properties.

| Material Designation Code | F-0000-10 | F-0000-15 | F-0000-20 |

|---|---|---|---|

| Density | 6.1 g/cm³ | 6.7 g/cm³ | 7.3 g/cm³ |

| Ultimate Strength | 120 MPa | 170 MPa | 260 MPa |

| Yield Strength (0.2%) | 90 MPa | 120 MPa | 170 MPa |

| Compressive Yield Strength (0.1%) | 110 MPa | 120 MPa | 130 MPa |

| Hardness | 40 HRF | 60 HRF | 80 HRF |

Iron-Copper and Copper Steel

PM iron-copper and copper-steel materials consist of a blend of elemental iron and copper powders, sometimes combined with graphite powder (carbon). These materials are widely used in medium-strength structural applications.

Examples of iron-copper materials include FC-0205, FC-0208, and FC-0508. Common sintered parts made from FC-0208 include oil pump rotors and gears, shock absorber parts, water pump pulleys, water pump flanges, timing sprockets, and more.

The following table shows the features of FC-0205 and FC-0208.

| Material Designation Code | FC-0205-40 | FC-0205-90HT | F-0208-50 |

|---|---|---|---|

| Density | 6.7 g/cm³ | 7.0 g/cm³ | 6.7 g/cm³ |

| Ultimate Strength (MPa) | 340 | 690 | 410 |

| Yield Strength (0.2%) (MPa) | 310 | / | 380 |

| Compressive Yield Strength (0.1%) (MPa) | 310 | 660 | 340 |

| Hardness | 60 HRB | 36 HRC | 73 HRB |

Copper-Infiltrated Iron and Steel

Copper infiltration is the process of filling the interconnected pores of powder metallurgy parts with molten pure copper with a lower melting point through capillary action.

Copper infiltrated parts are made by pressing iron-based powder metal parts into finished shapes and infiltrating the interconnected pores with copper-based materials during the sintering process. Copper infiltration can effectively improve the strength, hardness and impact properties of sintered parts.

In the MPIF 35 standard, copper-infiltrated parts are indicated by FX. For example, FX-0808 represents 8% copper and 0.8% carbon.

| Material Designation Code | FX-1010-25 | FX-1005-110HT | FX-2005-45 |

|---|---|---|---|

| Density (g/cm³) | 7.3 | 7.3 | 7.3 |

| Ultimate Strength (MPa) | 350 | 830 | 520 |

| Yield Strength (0.2%) (MPa) | 220 | / | 410 |

| Compressive Yield Strength (0.1%) (MPa) | 230 | 760 | 410 |

| Hardness | 65 HRB | 38 HRC | 85 HRB |

Stainless Steel – 300 Series Alloy

SS 316 and SS 304 offer good strength properties and corrosion resistance, making them suitable for a wide range of applications. SS 303 is easy to process, while SS 310 is commonly used as a refractory material.

Common applications of sintered stainless steel materials include valve guides, gears, and cams.

Common PM stainless steel materials properties.

| Material Designation Code | SS-303N1-25 | SS-304L-18 | SS-316L-22 |

|---|---|---|---|

| Density (g/cm³) | 6.4 | 6.9 | 6.9 |

| Ultimate Strength (MPa) | 270 | 390 | 390 |

| Yield Strength (0.2%) (MPa) | 220 | 180 | 210 |

| Compressive Yield Strength (0.1%) (MPa) | 260 | 190 | 200 |

| Hardness | 62 HRB | 45 HRB | 45 HRB |

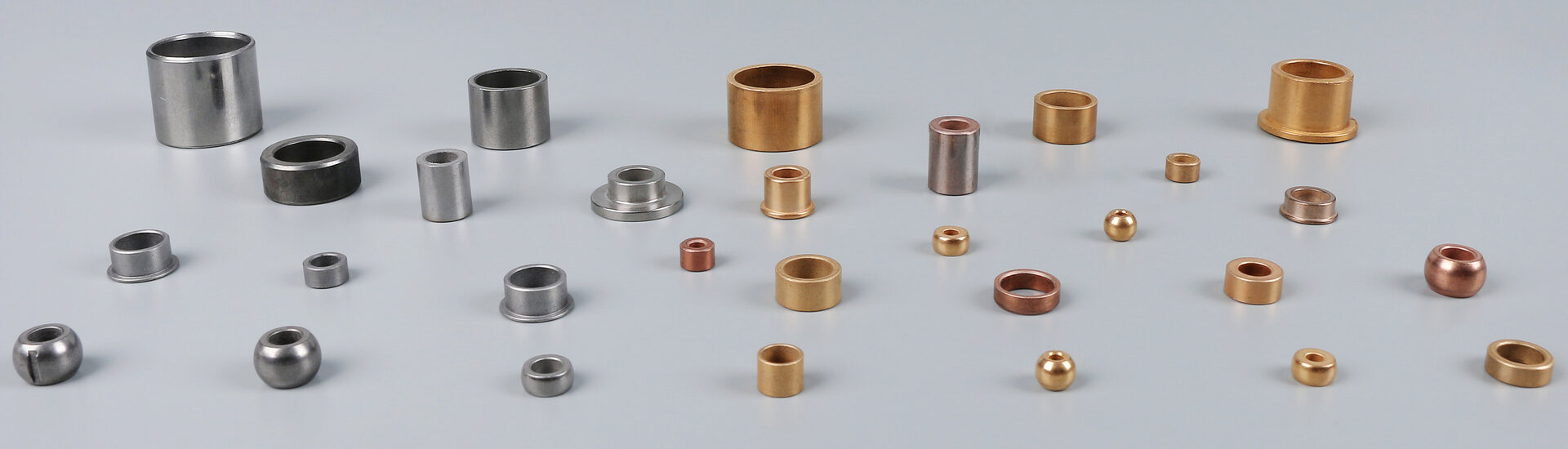

Materials Standards for PM Self-Lubricating Bearings

You might find self-lubricating sintered bushings used in various applications, such as power tools, washing machines, coffee machines, electric fans, sewing machines, copiers, and more.

The MPIF 35 standard defines the chemical composition, density, oil content, and crushing strength for different material designations of oil impregnated bushings.

The following table shows the oil content, density, and minimum crushing strength of some bronze, iron, iron-copper, and oil-impregnated bushings.

| Attribute | CT-1000-K19 | CT-1000-K40 | F-0000-K15 | FC-2000-K25 |

|---|---|---|---|---|

| Min. Crushing Strength | 130 MPa | 280 MPa | 100 MPa | 170 MPa |

| Min. Oil Content | 24% | 9% | 21% | 22% |

| Density (Oil Impregnated) | 6.0-6.4 g/cm³ | 7.2-7.6 g/cm³ | 5.6-6.0 g/cm³ | 5.6-6.0 g/cm³ |

| Fe | / | / | 96.2-100.0% | 75.7-82.0% |

| Cu | 87.2-90.5% | 87.2-90.5% | 0-1.5% | 18.0-22.0% |

| Sn | 9.5-10.5% | 9.5-10.5% | 0 | 0 |

| Graphite | 0-0.3% | 0-0.3% | 0 | 0 |

Materials Standards for Metal Injection Molded Parts

This document defines the chemical composition, mechanical properties, and physical properties of various MIM materials.

When formulating the technical specifications for MIM materials, the Metal Injection Molding Association uses the same grade system as AISI-SAE.

316L and 17-4 PH stainless steel are among the most commonly used stainless steel materials in metal injection molding.

Materials Standards for PF Steel Parts

This standard covers four powder forging materials: carbon steel, copper steel, and low-alloy PF-42XX and PF-46XX steel. It specifies the chemical composition, ultimate strength, yield strength, elongation, reduction of area, Rockwell hardness, impact energy, compressive yield strength, and other properties of PF materials.

ASTM Standard

ASTM B438

This standard is applicable to bronze-base PM oil impregnated bearings.

It divides bearings into different grades and types based on chemical composition and density range. It specifies the minimum oil content of each grade of bearings.

ASTM B438 provides a comprehensive specification for bronze-based powder metallurgy bearings. It guides manufacturers in producing high-quality bearings that meet industry standards.

This standard covers porous metallic sleeve, flange, thrust, and spherical bronze-base bearings. These bearings are made by conventional powder metallurgy process and are oil impregnated to achieve self-lubricating properties.

ASTM B439

The chemical composition of iron-based oil-bearings includes iron, copper, tin, pre-alloyed bronze or graphite.

ASTM B783 is applicable to iron-base PM oil impregnated bearings.

Iron-based oil-containing bearings have different models according to chemical composition. Each model of iron-based oil-containing bearings should meet the requirements of chemical composition, mechanical properties and oil content.

ASTM B783

This specification covers various ferrous powder metallurgy structural materials. It provides the chemical composition and mechanical properties of each grade of material. Its data are referenced to the MPIF.

JIS Z 2550

JIS Z 2550 is a Japanese industrial standard that specifies the general requirements for sintered metal materials.

It provides guidance on the following:

- Defining sintered metal material types and their chemical compositions.

- Setting standards for strength, density, hardness, and other mechanical properties of powder metallurgy materials.

- Describing procedures for verifying the quality and performance of sintered metal products.

The standard provides a reference for manufacturers and users to maintain consistency in materials and properties during the production and use of sintered metal parts.

DIN 30910

DIN 30910 is a German standard, issued by the Deutsches Institut für Normung, that specifies the properties and characteristics of sintered metal materials.

Below are some typical DIN materials, such as Sint-C 10, Sint-C 11.

| Materials | Sint-C 10 | Sint-C 11 | Sint-D 11 |

|---|---|---|---|

| Density (g/cm³) | 6.4-6.8 | 6.4-6.8 | 6.8-7.2 |

| Hardness (HRB) | >40 | >80 | >95 |

| Ultimate Strength (MPa) | 200 | 390 | 460 |

| Yield Strength (MPa) | 140 | 290 | 370 |

| Fe | Bal. | Bal. | Bal. |

| Cu | 1.5% | 1.5% | 1.5% |

| C | / | 0.6% | 0.6% |

PM Materials Comparison of Different Standards

The following table is a comparison of materials in different standards, including MPIF, JIS, DIN, ISO.

| MPIF Std/35 | DIN 30910-4 | JIS Z 2550 | ISO 5755/1 |

|---|---|---|---|

| F-0005 | SINT C01/D01 | P1033 (SMF 3030) | F-05 |

| FC-0205 | SINT C11/D11 | P2043 (SMF 4040) | F-05C2 |

| FN-0205 | SINT C32/D32 | P1094 (SMF 5030) | / |

| FD-0205 | SINT D39 | P3084 (SMF 5030) | FD-05N2C |

| C-0000 | / | P4045 | / |

| CZ-2000 | / | P4065 | / |

| CT-1000 | SINT A50 | P4011Z (SBK 1218) | C-T10 |

| FX-1005 | / | P2165 | FX-08C10 |

| FX-2005 | / | P2185 | FX-08C20 |

| SS-303L | / | P3504 | FL303 |

| SS-304L | / | P3514 (SMS 1025) | FL304 |

| SS-316L | SINT C40 | P3524 (SMS 1035) | FL316 |

| SS-410L | SINT C43 | P3535Z (SMS 2025) | FL410 |

| SS-430L | SINT C42 | P3544 (SMS 2035) | FL430 |

All the above data are for reference only.

BLUE is your reliable powder metallurgy supplier in China, with over 20 years of manufacturing expertise.

We provide more than 100,000 standard sintered powder metal parts, including oil pump rotors and gears, shock absorber components, powder metal gears, timing sprockets, water pump flanges, pulleys, and more—all with no tooling fees!

Visit our standard PM parts shop to find the perfect fit for your project!