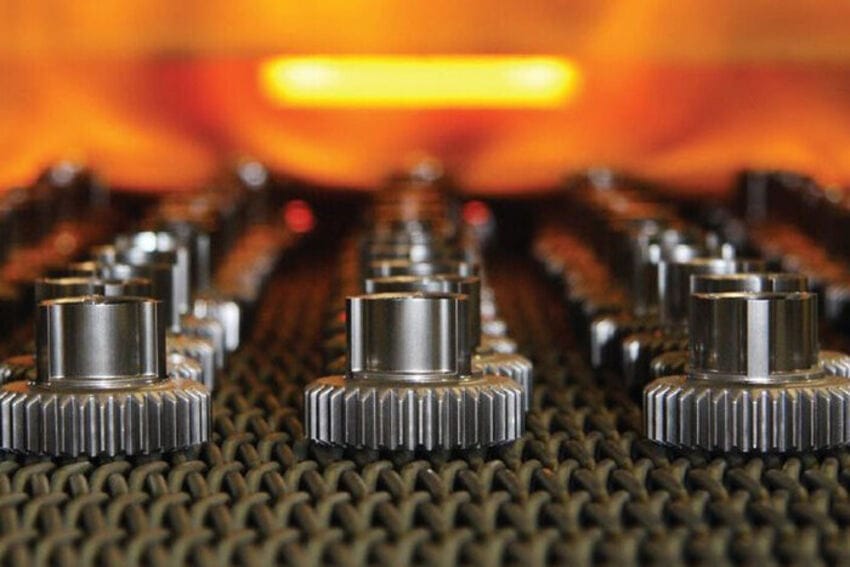

In the last few decades, powder metallurgy (PM) parts have emerged as an attractive manufacturing process for replacing wrought or cast components due to their design flexibility, low cost, tight tolerances, and good balance between ductility and tensile strength.

Joining is a fundamental process in mechanical manufacturing, used to connect parts made from the similar or different materials. You might be wondering: Is welding powder metal parts possible? Read on to find the answer you’re looking for.

Contents

Powder Metal Manufacturing

Powder metal manufacturing mainly includes: powder mixing, powder compacting, sintering.

Mixing and Blending

The purpose of mixing is to evenly combine the metal powder with binders. Adding binder is to increase the fluidity of the powder and reduce the demoulding force

Compacting

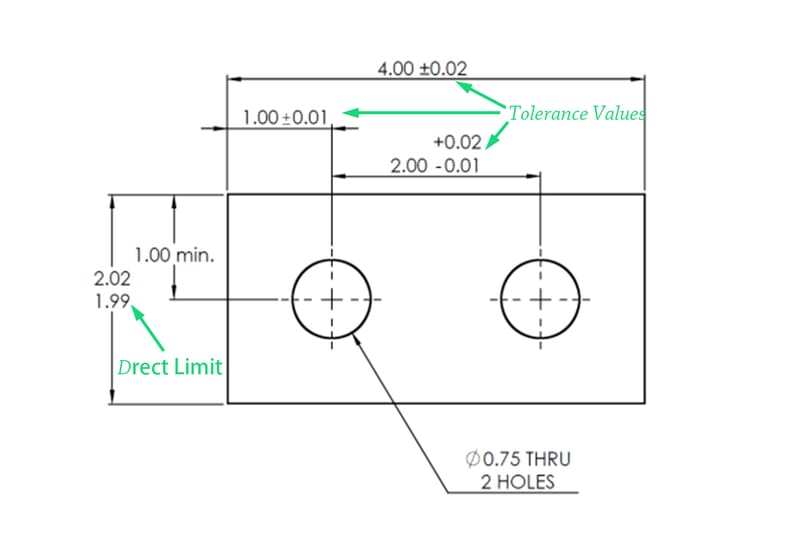

Mixed powder is pressed under high pressure (usually 400–800 MPa) using the powder metallurgy tooling, forming what is known as a “green compact.” The compacted metal powder is not strong enough and is only comparable to chalk.

Sintering

Sintering is performed at a temperature below the melting point of the metal, usually 70%-90% of the melting point. Sintering fuses the powder particles together, giving the part the desired strength and integrity.

Challenges in Welding Powder Metal Parts

As with other metal welding, the primary requirement for welding powder metallurgy parts is that no defects should be introduced. However, the following factors may affect the welding process.

Porosity

The porosity of powder metallurgy components affects thermal conductivity, which in turn affects welding parameters.

The porosity in the microstructure of sintered metal parts affects their welding, making it distinct from the welding of cast or forged components.

During welding, the heat affected zone of powder metallurgy components may crack. This is because the powder metal parts are porous and the bonding force between particles is limited, which cannot resist the higher stress caused by the increased hardenability of the heat affected zone.

Contaminants

If there are contaminants such as lubricants, plating fluids, and oils in the internal pores of sintered parts, it will affect the welding performance. Therefore, these impurities and contaminants must be cleaned before welding.

Carbon content

Most powder metallurgy parts are iron-based parts, and their carbon content varies. Sintered parts with low carbon content, less than 0.5%, are easy to weld, while those with high carbon content are difficult to weld.

Welding Technology of Powder Metallurgy Parts

Resistance welding

Resistance welding is joining two metal surfaces to a molten or plastic state by current and pressure and then metallurgically combine them.

The advantage of resistance welding is that it does not require welding materials and shielding gas.

Common types of resistance welding include the following:

- Spot welding

Spot welding is suitable for lap joining of thin plate sintered parts with a thickness of less than 3mm.

- Projection welding

Projection welding is ideal for joining high-carbon (0.4% – 0.8%) dense (6.5 – 7.5 g/cm³) powder metal parts to low-carbon steel parts.

- Seam welding

The sintered metal parts pass between two rotating disc electrodes to form a continuous weld seam with front and back overlaps. It is suitable for joining thin powder metal components.

- Flash welding

These welding processes are generally applicable to powder metallurgy parts, but the surface of the parts must be clean and free of impurities.

Brazing

Powder metallurgy products can also be joined together by brazing. Brazing is suitable for green compacts with higher density. When the product has more pores, part of the solder will be sucked in, resulting in insufficient solder on the welding surface.

Gas Tungsten Arc Welding (GTAW/TIG)

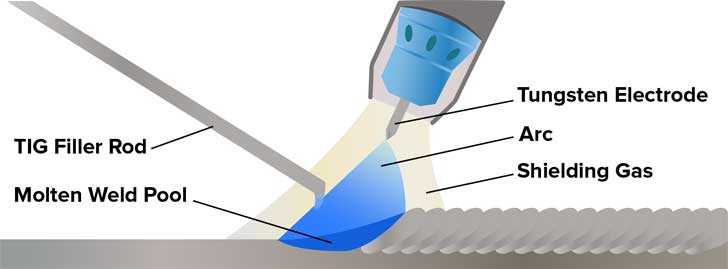

GTAW uses a non-consumable tungsten electrode to create a DC arc (for iron-based materials) that melts the materials being welded.

During the process, inert gases like argon or helium protect both the welding area and the electrode from atmospheric contaminants such as oxygen, hydrogen, and nitrogen.

When welding powder metal products with GTAW, filler metal can help compensate for the shrinkage that occurs due to particle melting and densification in the weld area. However, the thermal expansion coefficient, strength, and corrosion resistance of the filler metal must be compatible with the materials being welded.

In one case, welding two powder metal pcomponents using GTAW replaced a cast component in the truck differential, resulting in a 35% cost saving.

Gas Metal Arc Welding (GMAW/MIG)

GMAW uses a continuous wire electrode to generate an arc that heats the workpiece, fusing and joining the materials. GMAW can weld powder metallurgy materials containing mixed powders with high carbon content (0.3-0.9%).

Electron beam welding

Electron beam welding focuses high-speed electron streams into a beam to form a strong narrow heat source to join sintered metal parts. EBW is usually performed in a vacuum environment and is an advanced batch automated welding process.

Laser Beam Welding

Laser beam welding (LBM) is a highly automated process with high precision and minimal deformation. LBM fuses the workpiece materials together using a laser beam, such as a CO2 laser.

To reduce martensite formation, medium hardenability materials are generally preheated to 250-300°C before welding.

However, laser welding is more expensive than other welding processes.

Powder Metal Fusion Welding Tips

The most common issue you may face when fusion welding powder metal components is cracking in or near the weld. This usually happens due to stresses that develop as the weld metal cools and solidifies.

You can reduce the risk of cracking by:

- Preheating the parts to remove moisture (hydrogen) and reduce thermal gradients

- Post-heating after welding to relieve residual stresses

- Minimizing heat input to limit particle melting and solidification stresses

- Designing joints carefully to reduce stress concentration

Powder metallurgy parts that have been steam treated, copper infiltrated, or quenched and tempered are not suitable for fusion welding.

Material Selection for Welding Powder Metal Parts

- Atomized iron powder has lower residual impurities than sponge iron powder or other reduced iron powders. Therefore, for high-strength or fusion welding applications, you’d better use atomized iron powder.

- Carbon content has a significant effect on all weldability of powder metallurgy parts. Generally, the lower the carbon content, the better the weldability. But carbon can increase the strength properties of the material.

- When you use fusion welding, you’d better not use powder metallurgy materials with added sulfur. This is because sulfur may migrate to the grain boundaries during welding and cause thermal cracking.

- Nickel added to iron powder or steel powder can increase the toughness of the material, while having no effect on weldability.