Powder metallurgy (PM) is widely recognized as a green manufacturing process that uses metal powders to produce parts with minimal waste. It is well suited for making complex and high-precision components in large volumes. Typical powder metallurgy examples include sintered gears, oil pump rotors and gears, bushings, timing pulleys, ABS sensor rings, lock parts, shock absorber components, and sintered filters.

Contents

What is Powder Metallurgy?

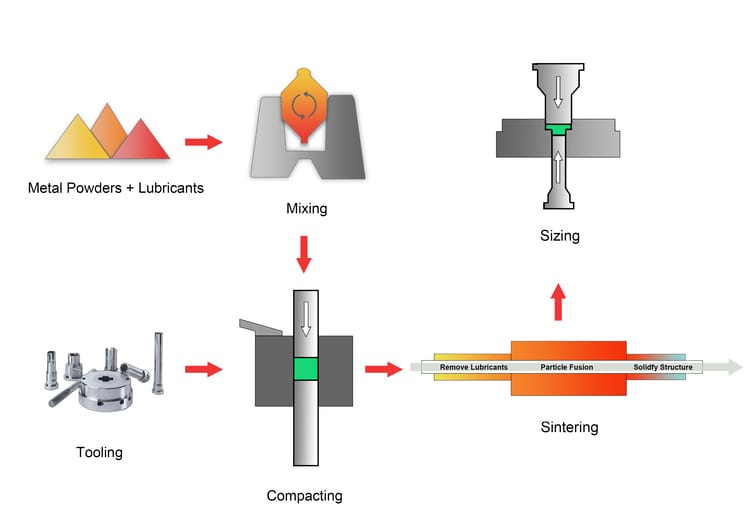

The powder metallurgy process starts by mixing the powders with binders to improve flowability and compressibility. The mixture is then compacted under high pressure in a die to form a solid shape, known as a green compact. After pressing, the compact is placed in a controlled atmosphere furnace for sintering—a heat treatment carried out below the metal’s melting point. This step bonds the particles together and increases the part’s strength and density without melting the metal.

PM is ideal for producing complex shapes, minimizing material waste, and enabling high-volume production with tight dimensional tolerances.

Examples of Powder Metallurgy Products

Here are some typical examples of powder metallurgy products.

Oil Pump Rotor

Oil pump rotors are responsible for drawing oil from the sump and pushing them through the engine to lubricate moving parts, reduce friction, and carry away heat. A typical rotor set includes an inner and an outer rotor that rotate together inside the pump housing. The inner and outer rotors must be precisely matched, with a radial clearance typically between 0.08 and 0.13 mm.

The powder metallurgy process is well suited for producing oil pump rotors. It enables accurate forming of complex shapes with tight tolerances, meeting the precision fit required between the inner and outer rotors. After sintering process, the rotor diameters can be further refined through sizing, a cold pressing step that improves dimensional accuracy.

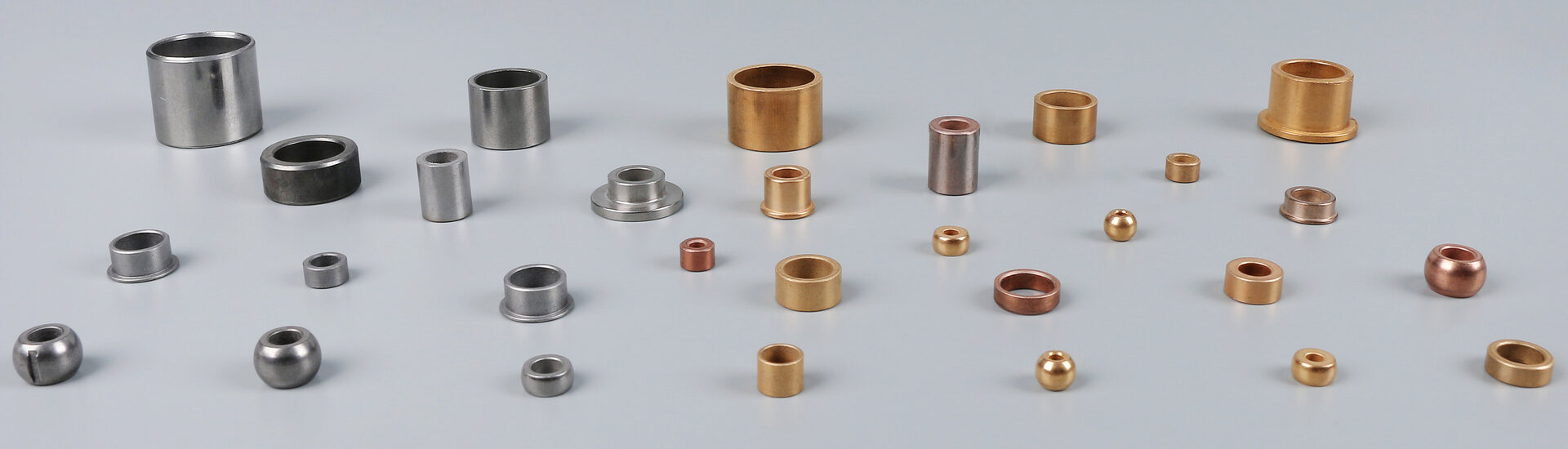

Sintered Bushing

Sintered bushings are self-lubricating bearings that are made by pressing metal powder (usually bronze or iron) into a green compact and then sintering it at a temperature below the melting point of the metal.

The sintering process creates a porous structure that allows the lubricant to be retained in the pores through vacuum oil impregnation. The bushing is therefore self-lubricating during operation.

Sintered bushings are widely used in applications that require low noise and continuous lubrication. Common uses include:

- Electric motors

- Household appliances (e.g., washing machines, fans, juicers)

- Office equipment (e.g., printers, copiers)

- Power tools

- Automotive systems (e.g., wiper motors, HVAC systems)

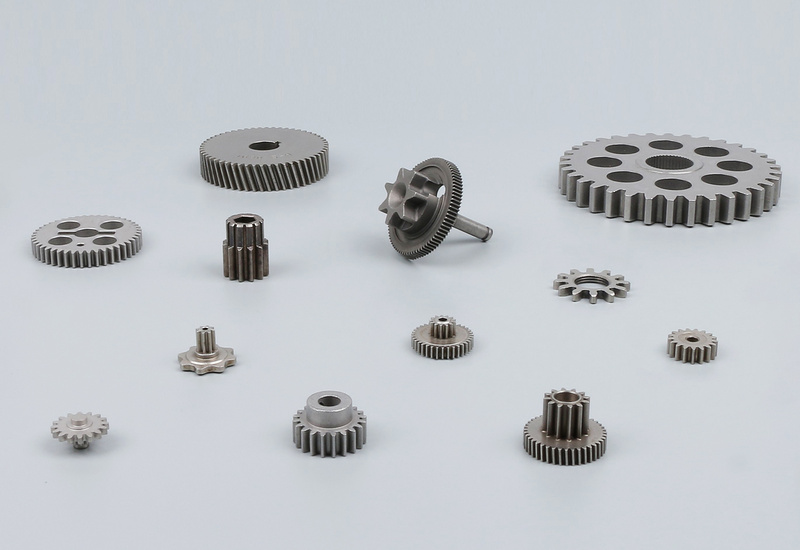

Powder Metallurgy Gear

Gears are vital transmission elements in machinery, yet traditional cutting routes involve many steps and waste significant material. Powder metallurgy compacting process directly forms the full tooth geometry so almost no secondary machining is required.

This simplifies the manufacturing process and shortens production time. With minimal material waste and over 95% material utilization, it also helps reduce costs and improve overall efficiency.

Most powder metallurgy gears are made from iron–copper alloys, pre‑alloyed steels, or sinter‑hardening steels. Popular forms include spur, helical, bevel, and planetary gears. They are widely used in automotive transmissions and steering systems, household appliances, power tools, medical devices, and lawn‑and‑garden equipment.

ABS Sensor Ring

The ABS ring, also known as a tone ring or reluctor ring, is a important component of a vehicle’s anti-lock braking system (ABS).

It is mounted on the wheel hub or axle and works with a sensor to measure wheel speed. As the wheel rotates, the teeth of the tone ring pass by the sensor, generating signals that are sent to the ABS control unit. These signals help the system detect wheel speed and prevent wheel lock-up, ensuring safe braking.

Sintered ABS rings are typically made from F-0000 material. They offer near-net-shape forming, are suitable for high-volume production, and provide excellent consistency and cost efficiency.

Water Pump Pulley

The water pump pulley is a rotating component mounted on the water pump shaft. It is driven by the engine’s crankshaft via a belt and transfers this motion to drive the water pump. Its main function is to keep the engine coolant circulating, which helps regulate engine temperature.

The water pump pulley is usually manufactured by powder metallurgy process, and the commonly used materials are FC-0205. FC-0208, FN-0205, FD-0208.

Water Pump Flange

A water pump flange is a precision-machined mounting component used to connect the water pump to the engine system. It serves as the interface between the pump shaft and the drive mechanism, allowing torque to be transmitted smoothly while maintaining accurate positioning of the pump impeller. The flange typically includes bolt holes, a central bore, and sealing surfaces that must be manufactured with tight tolerances to ensure leak-free operation and stable rotation.

Powder metallurgy is well suited for producing water pump flanges because it forms complex geometries with consistent accuracy and high material utilization. PM flanges often use FC-0205, FC-0208, FN-0205, and FD-0208 materials, which provide good strength, dimensional stability, and machinability. After sintering, the flange dimensions can be further enhanced through sizing or secondary machining to improve fit between the pump housing and the shaft.

Shock Absorber Part

Automobile shock absorbers are important components of the suspension system, directly affecting ride comfort, handling, and driving safety.

Shock absorber pistons, rod guides, and valves are key components of shock absorbers and are typical powder metallurgy products. These parts demand high precision, wear resistance, and strength to support reliable damping performance and smooth operation.

For example, the end face of a shock absorber piston has three annular mating surfaces. The flatness and dimensional differences of these surfaces greatly affect the fit between the piston and the cylinder, which in turn impacts vehicle safety.

Powder metallurgy achieves tight tolerances in shock absorber parts and provides a cost-effective solution for mass production.

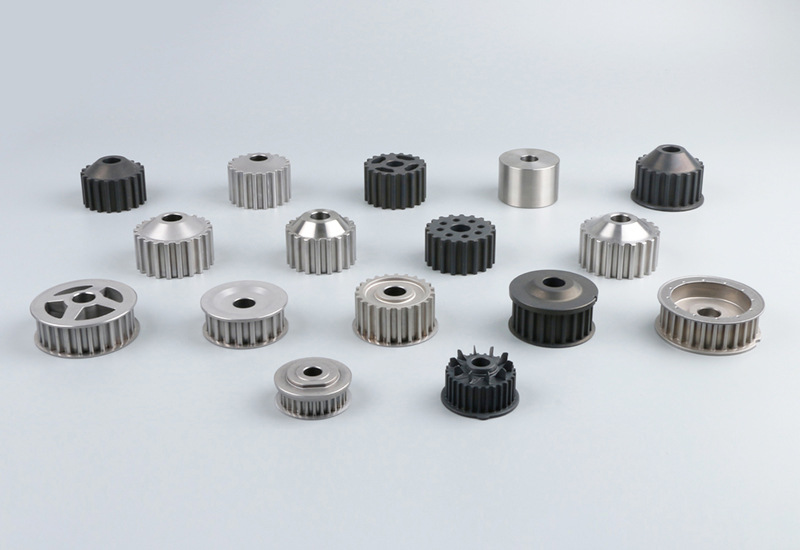

Timing Pulley

A timing pulley in an engine timing system is a toothed wheel mounted on the crankshaft or camshaft. It works with the timing belt to keep the crankshaft and camshaft rotating in precise relation, so that the intake and exhaust valves operate at the correct moments in the engine cycle.

Powder metallurgy is a practical choice for producing timing pulleys in engine systems. It allows both the tooth profile and mounting features to be formed precisely in a single compaction process, offering reliable part-to-part consistency. This approach supports high production volumes while keeping material use and manufacturing costs under control.

Lock Part

Another typical application of powder metallurgy technology is the production of door lock components, including cabinet locks, electronic door locks, smart door locks, UPVC door locks and mortise locks.

Compared with traditional metal manufacturing process, powder metallurgy technology significantly reduces manufacturing costs and enables rapid and large-scale production of lock components.

Typical sintered door lock components include lock cylinders, lock bolts, lock rods and lock pins. These parts are usually made of FC-0205 or FC-0208 materials and are steam treated to obtain a uniform surface appearance and higher corrosion resistance.

Sintered Filter

A sintered filter is a porous component made by pressing and sintering powdered materials. The particles fuse into a solid structure, and the spaces between them form tiny, uniform pores that allow fluids or gases to pass through while blocking contaminants.

These porous filters are strong, durable, and resistant to heat and corrosion, making them suitable for demanding uses such as chemical processing, gas purification, and liquid filtration.

BLUE is a leading powder metallurgy supplier in China, providing a wide range of standard powder metallurgy parts, all of which do not require tooling fees. You can go to OUR SHOP page to select the parts that are exactly the same as yours and place an order directly. Or you can directly download our powder metallurgy products list.

If you can’t find it, we support custom powder metallurgy parts.