There is growing interest in using hot isostatic pressing (HIP) technology to manufacture high performance components, primarily due to its ability to produce fully dense, near net shape parts—including large and complex geometries.

In contrast, conventional powder metallurgy parts typically have densities below 95%, usually ranging from 85% to 93%, while metal injection molded parts achieve higher densities, generally between 94% and 99%.

Contents

What is Hot Isostatic Pressing?

Hot Isostatic Pressing (HIP) is a manufacturing process that simultaneously applies high temperature (usually 800 to 1350°C) and high pressure (100–200 MPa) in all directions to densify powder materials or reduce porosity in cast and sintered parts.

History of Hot Isostatic Pressing

Hot isostatic pressing was invented in 1955 by Battelle Laboratories, who used it to diffuse bond nuclear feedstock. Today, hot isostatic pressing is widely used to densify powder metallurgy and sinter ceramic parts.

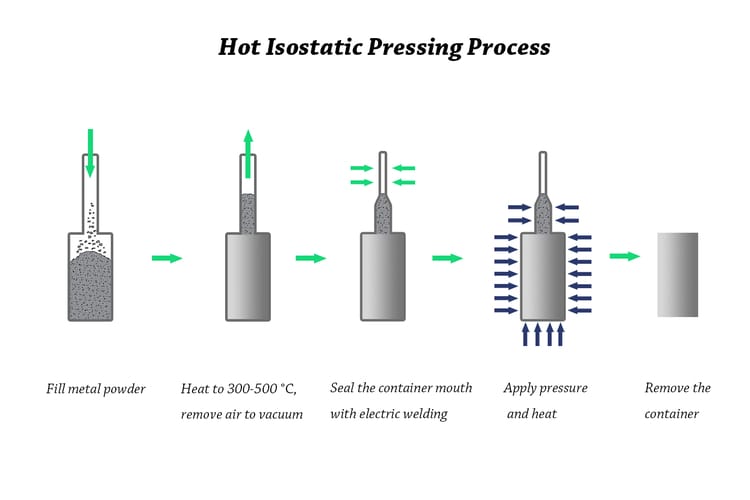

Hot Isostatic Pressing Process

Powder Production

The diameter of the powder particles utilized in hot isostatic pressing should not be too coarse or too fine. The particle size of metal powder is generally D50 40-90μm.

Gas atomized powder is most commonly used in HIP because:

- spherical powder shape

- high powder filling density

- narrow powder particle size range

- high powder purity and low oxygen content

Container Manufacturing

The container, or can, used to encapsulate metal powder undergoes significant volume shrinkage as the material consolidates into its final shape.

To maintain dimensional stability and allow for plastic deformation during this reduction, the can material must possess both high strength and good ductility.

For this reason, stainless steel and low carbon steel are commonly used for encapsulation cans, as they have good combination of strength and ductility.

Powder Filling and Degassing

Pour the powder into a container with a wall thickness of 2-3 mm. Then heat it to 300-500°C.

Before hot isostatic pressing, the metal powder enclosed in the steel can is degassed. Degassing is to evacuate the container by a vacuum pump to desorb the polluting adsorbed molecules of the metal powder.

Encaosulation.

After degassing, the container opening is clamped flat and then sealed by electric welding, a process called encaosulation.

HIP Process

The sealed can is heated in a heating chamber and pressurized with argon or nitrogen. Finally, removing the container by CNC machining or chemical methods.

Temperatures and Pressures

The following table shows the temperatures and pressures required for common materials used in hot isostatic pressing.

| Material | Temperature/°C | Pressure/MPa |

|---|---|---|

| Aluminum alloy | 500 | 100 |

| Copper alloy | 800–950 | 100 |

| Stainless steel | 1150 | 100 |

| Nickel 718 | 1185 | 100 |

| Ti-6Al-4V | 950 | 100 |

| WC-Co | 1700 | 100 |

| Tungsten | 1350 | 100 |

| Beryllium | 900 | 100 |

| Molybdenum | 1350 | 100 |

| Pure Iron | 950–1160 | 100 |

| Pure Nickel | 1100–1280 | 100–140 |

Advantages and Disadvantages of Hot Isostatic Pressing

Advantages of Hot Isostatic Pressing

Good Tensile Properties

The tensile properties of parts produced through hot isostatic pressing and sintering are generally equal to or superior to those made by traditional casting, forging, or rolling methods.

Design Flexibility

HIP process can produce parts that are not possible with traditional manufacturing processes, including those with complex three-dimensional shapes.

Reduce Welding

HIP can produce fully consolidated parts, minimizing the need for costly welded joints. This reduces production time and lowers overall manufacturing costs.

Save Material Costs

HIP is a near-net-shape manufacturing process with high material utilization and no secondary processing required. Compared with machining, this saves material costs and reduces manufacturing costs.

Uniform Density

Hot isostatic press applies uniform pressure to the metal powder from all directions, resulting in a uniform density and microstructure throughout the green compact.

Disadvantages of Hot Isostatic Pressing

Hot isostatic pressing has the above advantages, but also has some disadvantages including high equipment cost, limited production quantity and slow processing speed.

High Equipment Cost

HIP equipment is expensive, so it requires a large upfront investment.

Limited Production Quantity

HIP is usually suitable for small batch production.

Slow Processing Speed

Compared with other powder forming methods, such as traditional powder metallurgy processes, HIP production cycle is usually longer and production efficiency is lower.

Post Processing

Parts produced by HIP may require post-processing to achieve tight tolerances. This increases the total cost and production time.

Part Aize Limitation

Part size is limited by the capacity of hot isostatic pressing equipment.

Hot Isostatic Pressing Applications

Nuclear Power

Hot isostatic pressing has a wide range of applications in the manufacture of nuclear power plant (NPP) components, such as large parts used in the manufacture of the reactor pressure vessel (RPV).

Powder Metallurgy

HIP is used to densify powder metallurgy sintered parts and eliminate their residual porosity.

Diffusion Bonding

Hot isostatic pressing joining is a form of diffusion bonding, where high temperature and pressure are applied simultaneously to promote rapid atomic movement. This allows the closely contacting surfaces to bond in the solid state, without forming a liquid phase.

Ceramic

HIP is used in ceramic processing to increase density and improve mechanical properties, making it suitable for high-performance applications.

Casting

Castings often produce micro pores when the high-temperature liquid solidifies to room temperature, which is the cause of low-stress cracking or fatigue damage.

HIP can eliminate micro pores in metal castings and improve fatigue life.

Hot Isostatic Pressing Machine

Hot isostatic press mainly consists of three parts:

- Pressure chamber body

- Pressure system

- Heating system

The maximum working area of a hot isostatic press can reach 2 meters in diameter and 4.2 meters in height. The heating system typically uses Fe-Ar-Al alloy, tungsten, or graphite, allowing the powder to reach temperatures of up to 1350°C, 1600°C, or even 2200°C. A hot isostatic press uses high-pressure gas, typically argon or nitrogen, to apply hydrostatic pressure of 100–200 MPa to the powder.

Cold Isostatic Pressing vs Hot Isostatic Pressing

The following table shows the difference between hot isostatic pressing and cold isostatic pressing.

| Aspect | Cold Isostatic Pressing (CIP) | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Temperature | Room Temperature | High Temperature (typically 800–1350 °C) |

| Pressure Medium | Liquid (usually water or oil) | Gas (usually argon) |

| Pressure Range | 34.5–690 MPa | 100–200 MPa |

| Resulting Part | Green Compact (needs sintering) | Fully Dense |

| Materials Processed | Metal, Ceramic, Plastic powders | Mostly metals, alloys, Ceramics |

| Tooling | Flexible Molds (rubber or polyurethane) | Rigid Canisters |

| Production Use | Small Batch or Pre-sintering Step | Final Densification |

FAQ

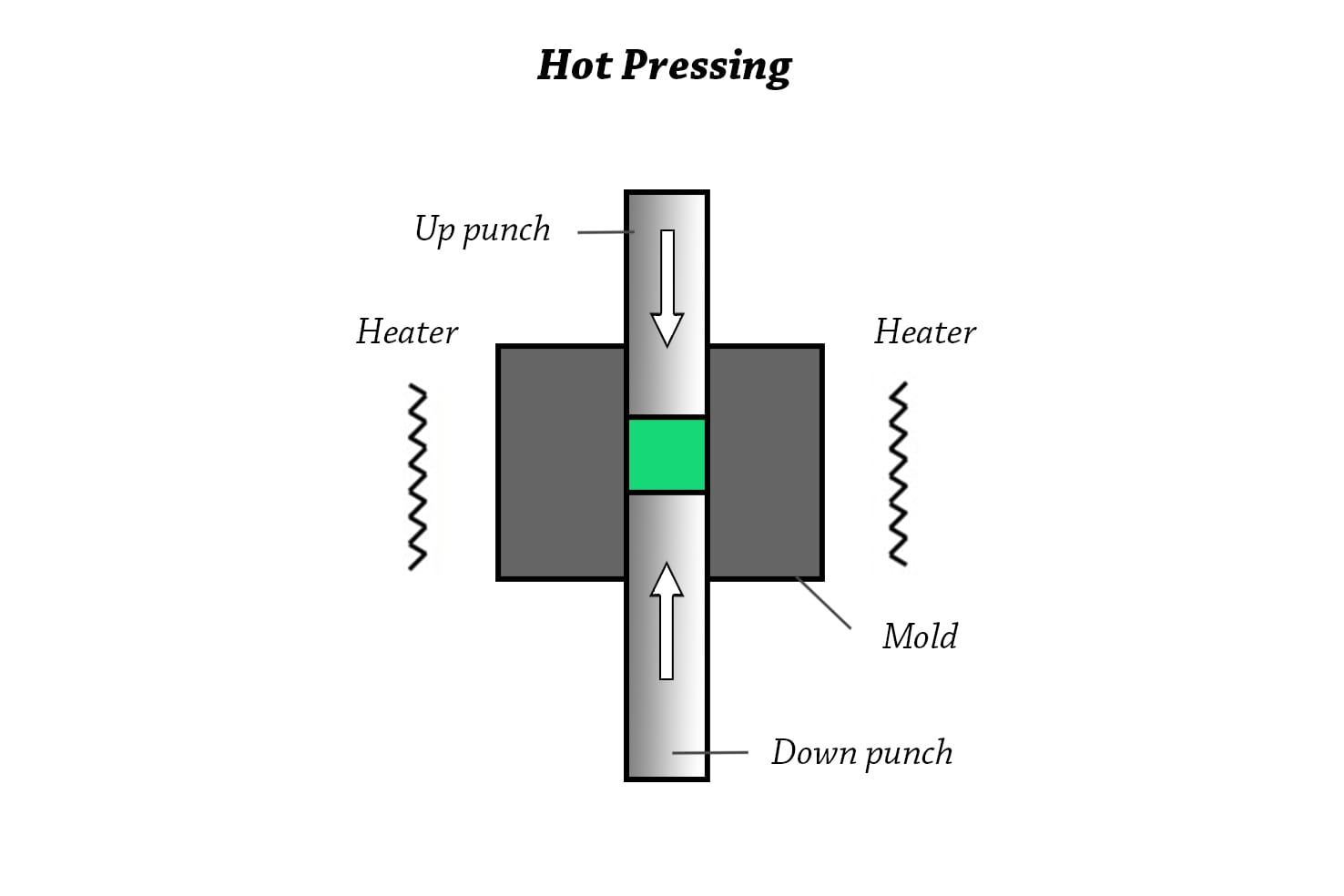

What is Difference between Hot Isostatic Pressing and Hot Pressing?

Hot isostatic pressing uses gas pressure to apply pressure in an isostatic manner (in all directions), while hot pressing uses a punch to apply uniaxial pressure (in one direction).

What is Sinter-HIP?

Sinter-HIP is developed from vacuum sintering and hot isostatic pressing, and is mostly used for sintering liquid cemented carbide. In the sintering HIP furnace. The workpiece is first heated to the sintering temperature by traditional methods, and a pressure of 0.1 to 30MPa is applied during the insulation stage.

This is because there is a little liquid between the powders, which reduces the friction, so the pressure does not need to be too high to reach full densification of the parts.