Copper powder has a bright orange-red color, excellent thermal and electrical conductivity, strong corrosion resistance, and good friction properties. As a result, it is widely used in sintered metal parts, printed circuit boards, friction materials, welding materials, and more.

As of 2023, the global copper powder market size is US$760 million. With the growing demand for copper powder, it is expected to reach US$1.12 billion by 2032, with a compound annual growth rate of 4.3%.

Contents

What is Copper Powder?

Copper metal powder is a finely divided form of copper metal with broad applications in various industries.

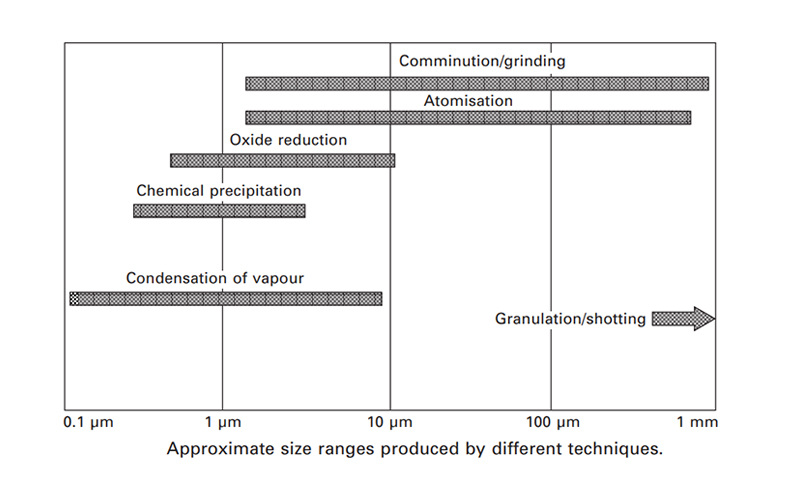

The particle size of copper powder usually ranges from 0.1 to 150 microns depending on the process of manufacturing and the specific reason it is required for. When used in electronics or for 3D printing, copper powder is refined to a size of 10 to 50 microns. In the case of metallurgy and the production of coatings copper powder having 10 to 100 microns is commonly used.

Types of Copper Powder

Metallic copper powder is categorized into several types based on the production process:

- Atomized copper powder

- Electrolytic copper powder

- Reduced copper powder

- Mechanical copper powder

Atomized Copper Powder

Atomized copper powders are produced by water atomization (10-150μm) or gas atomization (5-45μm). The method proceeds by spraying molten copper with a gas or liquid at a high velocity, so it turns into fine droplets. These droplets cool and solidify into spheres. This Cu powder is commonly utilized for powder metallurgy, thermal management, or 3D printing.

Gas atomized powder is spherical, has low oxygen content, and high powder purity. Water atomized powder is irregular in shape and has high oxygen content. Powder metallurgy process uses water atomized powder because of its low cost and narrow powder particle size distribution.

Electrolytic Copper Powder

Electrolytic copper powder is produced through an electrolytic process in which copper from the solution is deposited onto the cathode.

Electrolytic copper powder has several advantages, including high purity (>99%), consistent powder properties across batches, and low bulk density (0.55–3.55 g/cm³).

Its dendritic structure and excellent compressibility result in high green strength after pressing. However, the production process can lead to environmental concerns and relatively high manufacturing costs.

Reduced Copper Powder

The advantages of reduced copper powder are low manufacturing cost, high production efficiency, and large specific surface area of powder.

The disadvantages are low powder purity and the generation of polluting gases.

Hydrometallurgical Copper Powder

Hydrometallurgy is a method of extracting metals from ores or recycled materials using sulfuric acid or ammonia solution.

Hydrometallurgy is characterized by a high metal recovery rate, low production cost, and the ability to recover associated alloying elements.

The copper metal powder produced by this method has high purity (>99%), low apparent density and fine powder particles.

The following table enlists different methods of production of copper powder, along with their key attributes;

| Production Method | Purity | Shape | Applications |

|---|---|---|---|

| Gas Atomization | High | Spherical | Metal Injection Molding, Hot Isostatic Pressing, 3D Printing |

| Electrolytic | Very High | Dendritic | Conductive Inks, Electronics |

| Chemical Reduction | High | Irregular | Catalysts, Chemical Processes |

| Mechanical Grinding | Moderate | Irregular | Lubricants, Friction Materials |

Properties of Copper Metal Powder

The following table shows the properties of copper powder produced by different methods.

| Attribute | Atomized Copper Powder | Electrolytic Copper Powder | Reduced Copper Powder | Hydrometallurgical Copper Powder |

|---|---|---|---|---|

| Copper Content (%) | 99 – 99.5 | 99 – 99.5 | 98 – 99 | 99 – 99.5 |

| Weight Loss in H₂ (%) | 0.1 – 0.75 | 0.1 – 0.75 | 0.1 – 0.75 | 0.1 – 0.75 |

| Apparent Density (g/cm³) | 2.0 – 4.0 | 1.5 – 4.0 | 2.0 – 4.0 | 1.5 – 2.5 |

| Flow Rate (sec/50 g) | 20 – 35 | 30 – 40 | 20 – 35 | / |

| Green Strength (MPa) | 0 – 17.2 | 2.8 – 41.3 | 0 – 17.2 | 0 – 68.9 |

| Particle Fineness (-325 mesh, %) | 25 – 80 | 5 – 90 | 25 – 50 | 60 – 95 |

Copper Powder Applications

Powder Metallurgy

Powder metallurgy presses copper metal powder into a specific shape using a die, then sinters it at high temperature to form components with the desired mechanical properties.

Copper and copper alloy powders hold a important position among powder metallurgy materials. Copper powder is well-suited for producing self-lubricating sintered bushings, electrical components, iron powder additives, sintered filters, and friction materials.

3D Printing

3D printing, also known as additive manufacturing, is a near net shape technology that builds parts layer by layer. First, a layer of powder material is spread over a flat platform. A laser or electron beam then sinters the material at specific coordinates to form a solid cross-section. This process is repeated, layer by layer, until the entire workpiece is completed.

3D printing copper powder is generally gas atomized powder, and the median particle size D50 is generally 10-45μm.

Common 3D printing copper products include:

- Heat exchangers

- Induction coils

- Rocket engine components

- Electronics

- Antennas

- RF shielding

Electrical and Electronics Industry

They have found applications in conductive inks and coatings, and in PCBs (Printed Circuit Boards), to facilitate electrical connection. It increases the performance of electrical contacts and connectors as well.

Biological and Chemical

They are considered as a catalyst in industrial processes, copper powder helps increase the rate of efficiency of chemical reactions. Ideal for coating in healthcare and sanitation because of its anti-microbiotic properties.

Welding

In the welding and brazing processes, copper powder is utilized to strengthen the joint and increase thermal conductivity. It is used as a filler metal in brazing pastes and coatings to create corrosion resistant bonds in automotive, aerospace and industrial metal joining processes.

In MIG welding, adding copper powder to form metal matrix composites (MMCs) can increase the hardness of the fusion zone and heat-affected zone.

Copper Powder Price

The copper powder price fluctuates because of various reasons such as the level of

- purity

- parameter or particle size

- Powder production methods

The price of pure copper powder (purity ≥ 99.5%, 200 mesh) for powder metallurgy is about $11,513 per ton.

FAQ

1. Is It Safe to Handle Copper Powder?

Handling copper powder requires caution. During transportation or processing, fine powders may become airborne, posing risks such as inhalation and potential skin irritation or allergic reactions. To ensure safety, workers should wear gloves, masks, and other protective gear to minimize exposure to dust and prevent direct skin contact.