Angle Grinder Gear | BLUE

BLUE angle grinder gears have high tooth profile accuracy, high surface hardness, good wear resistance, and good core toughness. We offer standard sintered gears compatible with most angle grinder models—contact us to get free gear product lists!

Why Choose BLUE?

BLUE is your reliable supplier, offering high-quality angle grinder gears with precise tooth profiles, high strength, durability, and free mold design services.

BLUE High Quality Standards

BLUE guarantee the quality of your angel grinder gears with an IATF 16949: 2016 certified quality management system. Free samples are available for testing.

Standard PM Parts Shop

BLUE has a full range of standard engine valve guide in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

Free Mold Design Service

With over 20 years of expertise, BLUE provides free, high-precision mold design services tailored to your needs. Trust our experience to deliver for you!

BLUE Angle Grinder Gear in China

BLUE offers a variety of angle grinder gears—find exactly what you need for your applications or request a custom solution.

Angle Grinder Bevel Gear

BLUE angle grinder gears offer high tooth profile accuracy, good surface hardness, and excellent wear resistance

Angle Grinder Gear Set

BLUE angle grinder gears have a precise tooth profile, which enables smooth power transmission and minimizes noise and vibration during operation.

Sintered Angle Grinder Gear

Sintered angel grinder gear uses iron-based metal powder as raw material, such as FC-0205, FD-0205, and the material utilization rate is as high as over 95%.

BLUE Angle Grinder Gear Advantages

BLUE angel grinder gears are produced under the strict control of IATF 16949:2016.

Our powder metallurgy gears have high strength to withstand high torque and resist wear.

After heat treatment, the apparent hardness of our gears exceeds 40 HRC, with a core hardness of HV₀.₀₅ 400.

BLUE copper-infiltrated angle grinder gears feature a density of 7.4 g/cm³ and an apparent hardness of HRA90.

Heat Treatment of Sintered Gears

Quenching and Tempering

This process enhances the gear’s wear resistance and increases core strength.

Carburizing

Carburizing is a common heat treatment method for angle grinder gears. The material’s porosity significantly affects the depth of the hardened layer. Typically, the density of sintered gears should exceed 7.0 g/cm³.

Induction Quenching

Induction quenching creates a hard, wear-resistant surface on the angle grinder gear while preserving its internal toughness.

Adavantages of Sintered Angle Grinder Gear

Compared with the material utilization rate of cutting processing, which is only 54%, the material utilization rate of powder metallurgy gears is over 95%.

Compared with forged gears, sintered gears have fewer processes and less energy consumption.

Since sintered gears are die-formed, the shape and precision of the teeth are consistent.

Powder metallurgy can easily produce the ideal asymptotic tooth profile and full root fillet radius of gears.

Testing of Angle Grinder Gear

BLUE provides comprehensive testing services for powder metallurgy gears.

- Density: Tested according to GB/T 5163 using a densitometer.

- Dimensional Accuracy: Outer diameter and height measured with a micrometer.

- Gear Tooth Accuracy: Measured with a Gleason 300GMS.

- Surface Hardness: Tested using an HRB/HRC hardness tester.

- Effective Hardened Layer: Evaluated per GB/T 9540 with a microhardness tester.

- Tooth Resistance: Measured with a materials testing machine.

- Torsion Strength: Evaluated with a torsion testing instrument.

What is a Angle Grinder Gear?

Angle grinder gears transmit power from the motor to the rotating disc or wheel while adjusting torque and speed for efficient operation.

Most angle grinder gears are bevel gears, as they can transmit power at an angle (usually 90°) between the motor and the grinding wheel.

Bevel gears enable a compact design for power tools and ensure efficient torque transmission.

Custom Angle Grinder Gear Specifications

The table shows our manufacturing capabilities for customized angel grinder gears, including material, density, hardness, and bore tolerance.

| Attribute | Value |

|---|---|

| Material | FC-0205, FC-0208, FN-0205, FD-0205, FX-0208, SMF4040, D39 |

| Density | 6.8-7.0g/cm3 |

| Hardened Hardness | Min. 40 HRC |

| Bore Tolerance | ±0.01 mm |

| Accuracy of Gears | DIN/ISO 8 |

Powder Metallurgy Manufacturing Process

Powder metallurgy is a precision manufacturing process with a continuing and stable accuracy of up to 0.01mm, which requires strict control at each stage to ensure the quality of the final part. Any deviation or error during the process may result in the rejection of the entire batch.

Designing

Mold design is a critical process that must consider the desired part geometry, material properties, production volume, and cost-effectiveness.

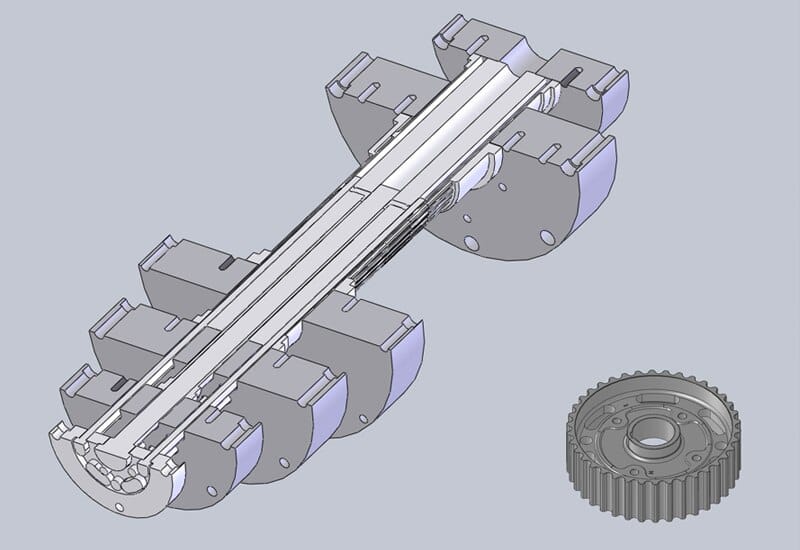

Tooling

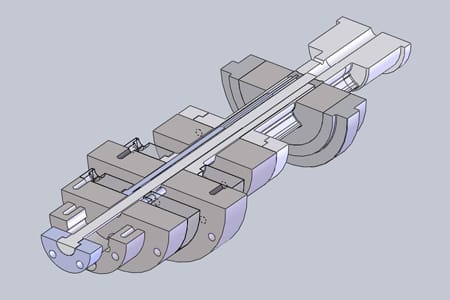

Powder metallurgy tooling includes upper and lower punches, die, and core rod. The mold needs to have excellent strength, hardness and wear resistance.

Mixing

Mixing is the process of blending metal powder with binders to improve its uniformity and fluidity, promoting better material consistency.

Compacting

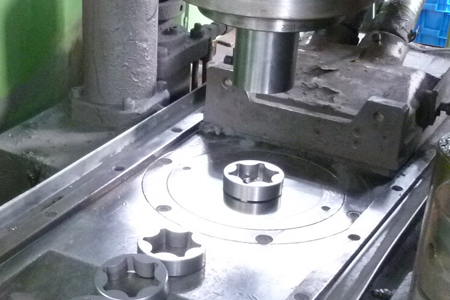

Conpacting is a process that presses metal powder into mold cavity through powder compaction machine to get a green compact part.

Sintering

Sintering heats the green compact to a temperature below its melting point in a controlled atmosphere to obtain the desired mechanical properties.

Sizing

Sizing corrects dimensional deviations after sintering and enhances product accuracy. It requires an additional, simpler set of molds compared to the forming mold.

Machining

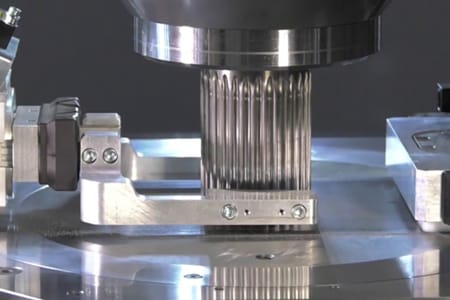

Machining can achieve complex shapes that cannot be pressed by powder metallurgy, such as transverse holes and screw threads.

Tumbling

Tumbling removes burrs and flash from a part's surface by vibrating it with abrasive media, such as stone or ceramic, resulting in a smoother finish.

Blackening

Blackening process, or steam treatment, forms an oxide layer to prevent rust and increase hardness, offering a cost-effective solution.

Hardening

Hardening enhances the material's strength and hardness through carburizing or nitriding, resulting in improved wear resistance and fatigue life.

Inspecting

The inspecting process is always a critical step that ensures quality and performance through BLUE inspection standards before shipping.

Packaging

BLUE's packaging process uses anti-rust paper, vacuum, blister and other methods to ensure that the product is intact during transportation.

BLUE's Powder Metallurgy Manufacturing Equipment

BLUE has a complete range of advanced powder metallurgy production equipment, including 25T to 1000T compaction press, conveyor belt sintering furnace, vacuum sintering furnace, sizing press, CNC machining equipment, hardening furnace, etc.

Related Powder Metallurgy Auto Parts

As a leading powder metallurgy supplier in China, BLUE provides a variety of standard PM parts, including powder metallurgy gears, oil pump rotors & gears, synchronizer hubs, and timing chain sprockets, all without tooling fees.

Powder Metallurgy Gear

Powder metallurgy gears offer high material utilization, precise tooth profile, excellent wear resistance, and the option for oil impregnation to enhance self-lubricating properties.

Oil Pump Gear

Our oil pump gears offer good surface finish, tight dimensional accuracy and excellent position tolerances to deliver optimal engine performance.

Synchronizer Hub

BLUE synchronizer hubs feature precise internal and external spline tooth profiles, good durability and high strength.

Timing Chain Sprocket

BLUE timing chain sprockets with precision teeth profile and holes, which fit perfectly with your chain and timing sprocket.