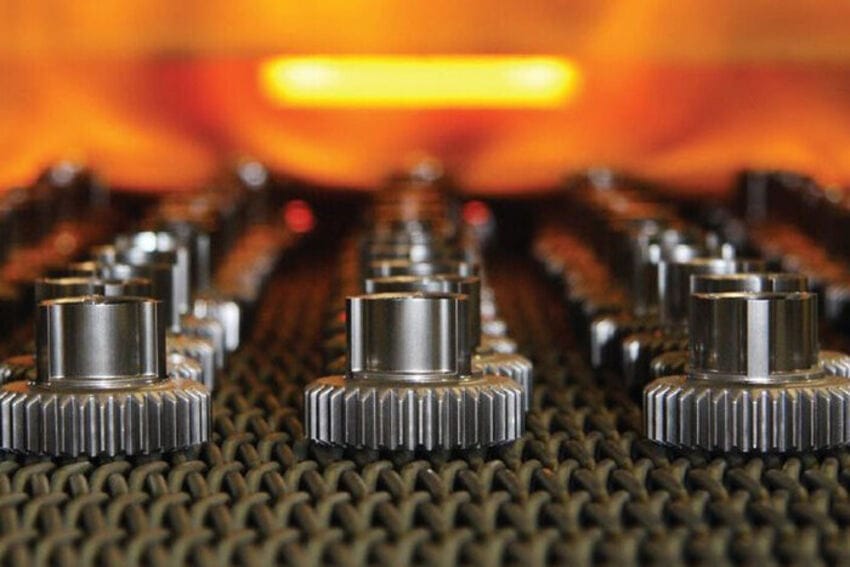

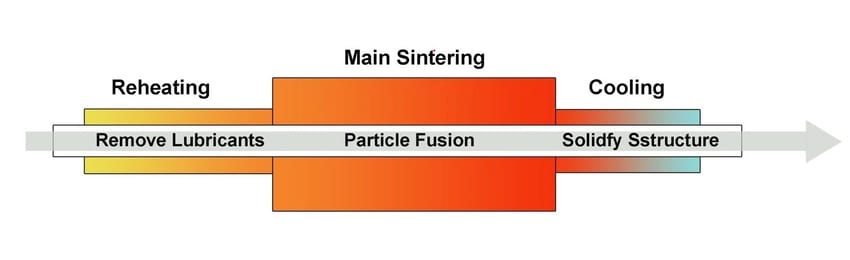

Sintering, also called frittage, is a process that densifies and bonds powder particles into a solid part by applying high temperatures below their melting point. The most common sintering is powder metallurgy sintering, which is used to increase the strength, density, and desired mechanical properties of powder metal parts.

Contents

What is Sintering Process?

Sintering heats powder, causing atoms to diffuse, particles to move closer together, surface area to decrease, and the shape to change.

Stages of Sintering

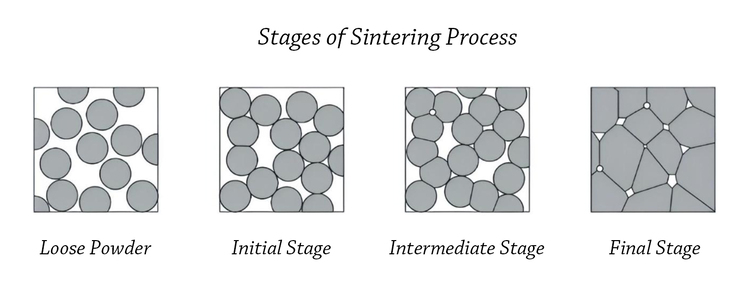

Generally, the sintering process is divided into three stages: initial stage, intermediate stage, and final stage.

Initial Stage

Powder particles form contact points by diffusion. Necks begin to form at the contact points and the material begins to densify slightly. At this stage, most of the pores in the part are interconnected.

Intermediate Stage

The necks between adjacent powders have grown and are in contact with each other, that is, entering the intermediate stage. This leads to a decrease in porosity and a significant increase in density.

Final Stage

At this point, most of the pores are isolated. The gas in the pores slows down further densification.

When the workpiece density reaches 92%, all pores are almost not connected. In addition, in the final stage, the grain growth rate is significantly accelerated.

Sintering Temperatures

The sintering temperature of metals is between 60% and 80% of their melting point.

Here are some common conventional metal sintering temperature:

- Iron sintering temperature: 1120-1150 °C(2048-2102°F)

- Copper sintering temperature: 800 °C

- Stainless steel sintering temperature: 1250 °C.

- The sintering temperature of ceramics is generally between 1000 and 2000 °C.

Sintering Atmosphere

The sintering atmosphere affects the mechanical properties and appearance of the final product. Common sintering atmospheres include: hydrogen, nitrogen, argon, vacuum, and decomposed ammonia. Its main functions are as follows:

- Prevent outside air from entering the sintering furnace and causing oxidation or decarburization of the workpiece.

- The sintering atmosphere helps to reduce the oxide layer on the surface of the compacted powder.

- Helps burn off lubricants and adhesives in the workpiece.

Types of Sintering Process

Common sintering process types include: solid phase sintering, liquid phase sintering, reaction sintering, microwave sintering, spark plasma sintering.

Solid State Sintering

Solid state sintering is a diffusion-driven process that bonds and densifies powders below their melting point without forming a liquid phase. It relies on atomic diffusion along grain boundaries to reduce surface energy and produce a dense, stable microstructure.

liquid Phase Sintering

Liquid phase sintering is well-suited for materials that are difficult to densify by solid-state sintering or have high melting points, such as tungsten carbide and silicon carbide. The raw materials used in liquid phase sintering are usually powders of multiple elements. When the sintering temperature is higher than the melting point of one element or exceeds the eutectic or peritectic point between the powders, a liquid phase will be produced.

Liquid phase sintering can effectively increase the sintering rate because the capillary force of the liquid phase can condense the powder and the atoms diffuse faster in the liquid than in the solid.

Permanent liquid phase sintering

Permanent liquid phase sintering is when the liquid phase always exists during the sintering process, such as the sintering of W-Cu powder.

Transient liquid phase sintering

Transient liquid phase sintering refers to a process in which a liquid phase forms during the early stage of sintering but solidifies in the later stage.

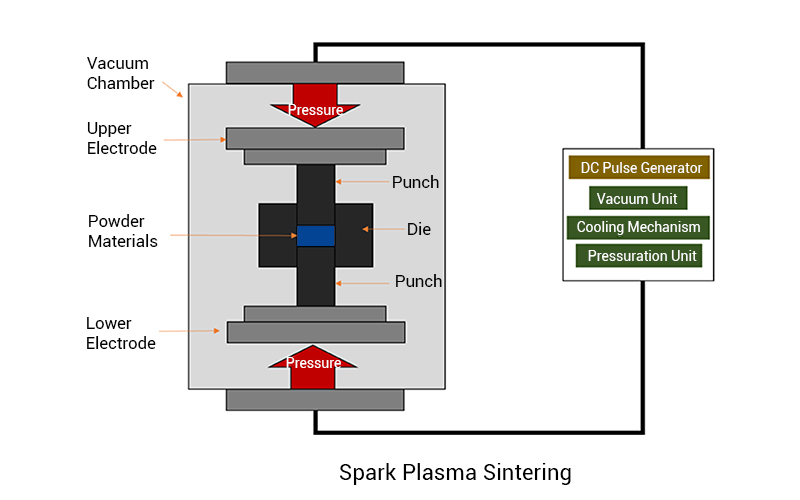

Spark Plasma Sintering

Spark plasma sintering (SPS), also known as field-assisted sintering (FAST) or electric discharge sintering, is a pressure-assisted pulsed-current method used for fabricating ceramics, metals, and hard materials.

SPS passes thousands or even tens of thousands of direct current pulses through the workpiece, with a heating rate reaching up to 600°C/min. By combining high current, rapid heating, high temperature, and high pressure, SPS densifies parts quickly and efficiently.

Microwave Sintering

In recent years, microwave sintering has emerged as an effective method for ceramic manufacturing. Unlike traditional pressureless sintering, it uses the material’s dielectric loss to absorb microwaves and generate heat internally. This allows the ceramic blank to heat rapidly and uniformly from within, enabling shorter sintering times, lower temperatures, and improved energy efficiency.

Microwave sintering can produce complex-shaped ceramics with finer, more uniform microstructures and higher density and strength. For example, Janney successfully sintered Al₂O₃ at 1200 °C in 60 minutes—250 °C lower than conventional methods.

Pressureless Sintering

Pressureless sintering is the most widely used sintering method, which requires only high temperatures and no external pressure to fuse the powder particles together. The convention powder metallurgy sintering process is pressureless sintering.

Reactive Sintering

Reactive sintering is a type of sintering process where chemical reactions occur simultaneously between the metal powder, leading to the formation of liquid phases or compounds within the material.

Reaction sintering can increase the density of green compact to more than 95% in a few minutes. However, due to the liquid phase generated inside, the workpiece is prone to deformation. It is commonly used to form advanced ceramic materials, such as silicon carbide (SiC) and silicon nitride (Si₃N₄).

Materials Used for Sintering

The sintering process can process a wide range of materials, mainly as follows:

Metals

Most metals can be made by sintering, including, iron, iron-copper alloy, bronze, brass, pure copper, 300 series and 400 series stainless steel, nickel alloy, alloy steel, titanium alloy, soft magnetic composite materials.

These materials can be formed by die compaction, metal injection molding, 3D printing, and then sintered into final parts.

Ceramics

Ceramics have extremely high melting points and are difficult to process using traditional manufacturing processes.

Sintered ceramics include: aluminum oxide, aluminum nitride, zirconium oxide, silicon nitride, boron nitride and silicon carbide.

Ceramics are usually formed by cold pressing, injection molding or isostatic pressing and then sintered.

Plastics

Sintered plastics have a wide range of uses, including mufflers, silencers, etc. Sintered plastic materials include: PP, PE, UPE, PA, PTFE, PVDF. Sintered plastics have high filtration efficiency and light structure.

Sintering Furnace

Conventional powder metallurgy sintering furnaces mainly include the following types:

Conveyor Belt Sintering Furnace

The operating temperature of conveyor belt sintering furnaces is typically below 1150°C, limited by the heat resistance of the belt material. As a result, these furnaces are generally used for iron-based and copper-based products. The conveyor belt usually moves at a speed of 50 to 250 mm per minute, with a standard width of around 500 mm.

Pusher Sintering Furnace

A pusher sintering furnace moves products through the heating zones using a push rod, offering a high level of automation and continuous operation.

Vacuum sintering furnace

Vacuum sintering furnaces can reach very high temperatures, up to 2500°C or higher, making them suitable for sintering high melting point materials such as ceramics, tungsten carbide, and molybdenum. However, their main drawback is relatively low production efficiency.

Advantages and Disadvantages of Sintering

Advantages of Sintering

The sintering process offers the following advantages:

- Parts manufactured by sintering have high consistency in part quality from batch to batch.

- The process can achieve tight tolerances.

- Powder metallurgy sintering is cost-effective in large-scale production.

- Sintering is near-net shape and does not require secondary finishing operations.

Disadvantages of Sintering

It also has some disadvantages:

- Conventional sintered parts have pores and their mechanical properties may not be as good as those of machined or forged parts.

- Conventional powder metal sintering process requires a long sintering time.

- The press-sinter method also depends on a precision powder mold, making it less suitable for small-batch production.

Looking for a sintered products manufacturer? BLUE is a trusted powder metallurgy supplier with 20 years of experience and ISO 9001:2015 certification. We provide a wide range of standard sintered metal parts with no tooling fees. Visit our shop to find the right fit for your project, or let us customize parts for you—we also offer free mold design services.

FAQ

What is the Process of Sintering in Metal Manufacturing?

Sintering in metal manufacturing is a thermal process that strengthens compacted metal powders by heating them to just below their melting point. During this stage, atomic diffusion occurs at particle contact points, forming metallurgical bonds and reducing porosity. The result is a dense, high-strength component whose final geometry and properties are defined by the original powder compact.

How Long does Sintering Take?

It depends on the sintering method.

Conventional powder metallurgy sintering takes about 4 hours.

Spark plasma sintering only takes about 5-10 minutes.

What is the Difference between Sintering and Annealing?

Sintering transforms the compacted powder into a component with the desired mechanical properties.

Annealing is a heat treatment process that improves the properties of solid metals by reducing hardness and restoring ductility.

What is the Difference between Sintering and Melting?

Sintering is performed below the metal’s melting point, typically at 70–90%, bonding particles without turning them into liquid.

In contrast, melting fully liquefies the metal, as seen in casting processes.