Sintered metal is widely recognized as a green manufacturing method, producing precision components from metal powders with minimal material waste.

Unlike traditional processes such as casting or machining, sintering yields near-net-shape parts that often require little to no post-processing.

These sintered metal products appear in a wide range of applications—from automotive systems and industrial machinery to medical devices and consumer products. In this article, you’ll learn what sintered metal is, how it’s made, and where it’s used.

Contents

What is Sintered Metal Product?

Your manufacturers make powder metallurgy parts by compacting metal powders and then sintering (heating) them to bind the particles together without melting them. Sintered metal products include sintered structural parts, sintered metal bushings, sintered filters, sintered ceramics, and MIM parts.

Sintered Metal Materials

Common sintered metal materials include iron, copper, stainless steel, titanium, etc.

Sintered Iron

Iron is cost-effective, offers strong mechanical and magnetic properties, and is commonly used in your structural components.

Sintered Stainless Steel

Sintered stainless steel provides excellent corrosion resistance due to its high chromium content. Common types are 300 and 400 series.

Sintered Copper

Sintered Copper and its alloys have good corrosion resistance, along with excellent electrical and thermal conductivity. Sintered copper is often employed to make self-lubricating sintered bearings.

Sintered Nickel

You may see nickel elements in aerospace engine parts because of its strong resistance to high temperatures and corrosion.

Sintered Titanium

Titanium and titanium alloy is lightweight, biocompatible, and supplies exceptional strength and corrosion resistance.

Before & During Powder Metal Sintering Process

Understanding the powder metallurgy process offers you insight into the sintering process.

Mixing

In order to increase the bonding strength between the powders, we evenly mix the metal powder with binders.

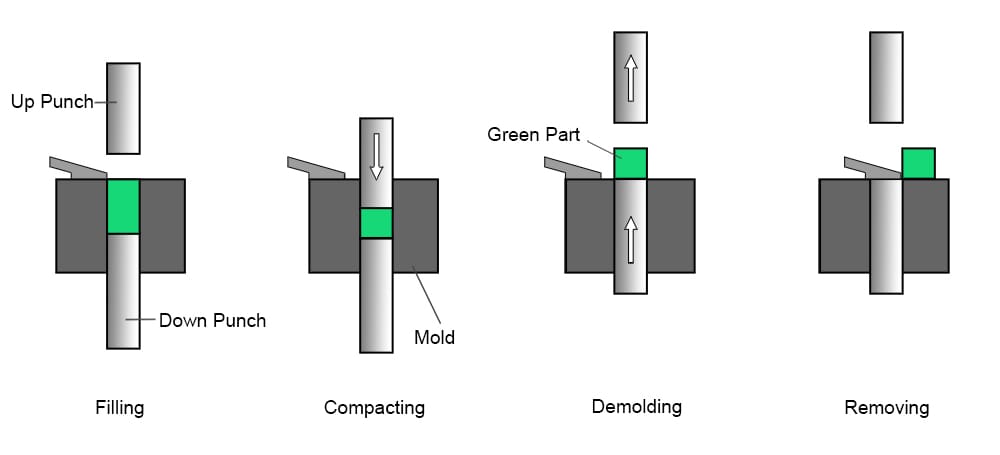

Compacting

The loose metal powders are pressed under high pressure (common 400-800MPa) to form the shape of final products. However, at this stage, the bonding between the powder particles is weak, with a bending strength of only about 15 MPa, which is only as strong as chalk. The pressed powdered metal, called the “green compact”, must be sintered to achieve the mechanical and physical properties you want.

Sintering

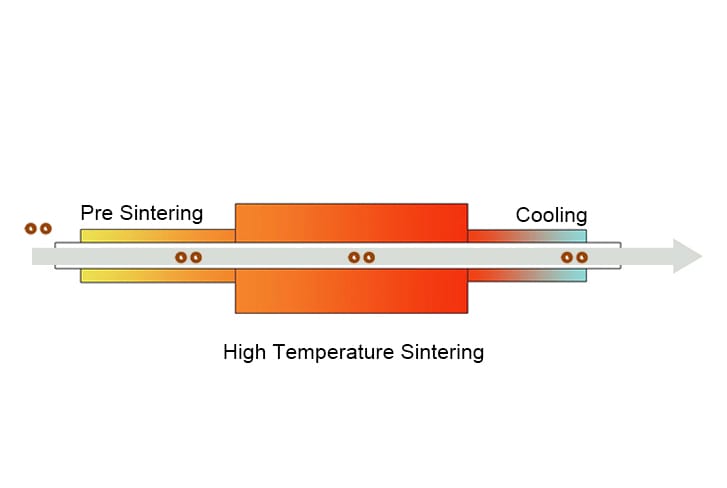

Sintering is divided into three main stages:

Pre sintering

The main purpose of this process is to remove binders from the green compact to prevent it from hindering the bonding and densification of powders.

Another is to reduce the oxides on the surface of the metal powder.

Pre-sintering is usually carried out in the front row of the continuous sintering furnace. Besides, at this stage, the pre-sintering temperature is frequently between 500 and 900°C.

High Temperature Sintering

Simply put, sintering is the atomic movement of powder particles at high temperatures, which shortens the distance between powders and reduces the surface area.

During high-temperature sintering, the powder particles draw closer, the part density increases, and the mechanical properties improve.

Cooling

Sintered PM parts must be cooled slowly from sintering temperatures to below 100°C to relieve thermal stress and prevent defects from rapid cooling.

Benefits of Sintering

Sintered metal pcarts have the following significant advantages.

Near Net Shape

Powder metal products can attain complex shapes, such as teeth and splines, directly through die compaction without secondary CNC machining.

High Dimensional Accuracy

The dimensional tolerance of sintered metal parts typically ranges from IT8 to IT9, and can improve to IT5 or IT7 after sizing process.

Self-Lubricating Properties

After sintering, your powder metal parts have interconnected pores that can be oil impregnated, giving self-lubricating properties. Self-lubricating sintered bushings and bearings are typical examples.

Green Technology

The powder metallurgy process is recognized as a green and sustainable manufacturing process, with a material utilization rate exceeding 95% and low energy consumption.

Applications of Sintered Metal

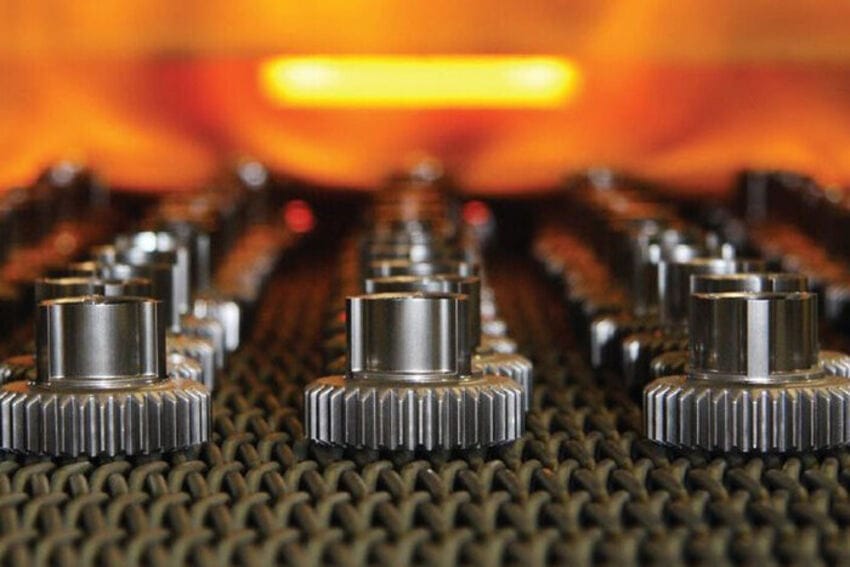

PM parts are widely used in various industries such as automobiles, motorcycles, home appliances, power tools, etc.

Motorcycle

You might also find some shock absorber parts, such as valves, pistons, and guides in motorcycles, made by sintering.

Automotive

Automobiles are the largest application market for sintered metal parts.

Valve Guides

Valve guides maintain proper alignment of the valves within the combustion chamber, allowing smooth vertical movement. In addition, they transfer heat from the valve stems to the cylinder head to dissipate heat.

Main Bearing Cap

Main bearing cap, also known as the crankshaft cap, supports the crankshaft, facilitating smooth rotation and distributing the loads generated by engine combustion throughout the engine block.

Crankshaft Sprocket

Crankshaft sprocket is a gear that connects the crankshaft to the timing chain or belt, keeping the camshaft and crankshaft synchronized. This is very important for the intake and exhaust valves to open and close at the correct intervals.

Synchronizer Part

Powder metal gears in transmissions have high tooth accuracy and wear resistance, delivering smooth and reliable torque transmission.

We manufactures sintered parts for synchronizers, including:

- Synchronizer hub

- Synchronizer blocking ring

- Synchronizer sleeve

ABS Ring

The ABS sensor ring is a metal gear component in the Anti-lock Braking System (ABS) that works with the wheel speed sensors to monitor wheel rotation and prevent the wheels from locking during braking.

Household Appliances

PM is cost-effective and suitable for mass production of air compressor valve plates, pistons, and connecting rods in household appliances.

Power Tools

Powder metallurgy process accomplish strict tolerances and high tooth accuracy, suitable for manufacturing components in power tools such as angle grinders, chainsaws, and nail guns.

Bevel gears, helical gears, and planetary gears in power tools are mostly manufactured by PM.

Sintered Metal Filter

Another application of sintered metal is filtration system. After sintering, it forms interconnected pore structures, giving the sintered metal filter uniform porosity, micron-level filtration accuracy, and high efficiency.

Sintering Vs. Melting

While they may seem similar due to the application of heat, sintering and melting fundamentally differ in their mechanisms, temperature requirements, applications, and outcomes.

Temperature

Sintering: Conducted at temperatures below the metal’s melting point, generally 60%-90% of the melting point.

Melting: Conducted at temperatures above the melting point, transitioning the metal from a solid to a liquid state.

Bond Formation

Sintering: Bonds form through diffusion, neck formation between particles, and sometimes the presence of a liquid phase (liquid-phase sintering).

Melting: Bonds are created upon solidification after cooling from the liquid state.

Sintering can achieve the desired mechanical properties without completely melting the metal, which makes it easy to process metals with high melting points.

Why Choose BLUE Powder Metallurgy?

BLUE is a dedicated sintered metal product manufacturer in China with more than 20 years of manufacturing experience.

We offer a wide range of standard sintered powder metal parts such as oil pump rotors & gears, shock absorber components, gears, timing sprockets, water pump pulleys, etc. without tooling fees!

Visit our standard parts shop to find the exact match for your projects!

FAQ

What is SIntered Steel?

Sintered steel is a solid material produced using powder metallurgy, in which steel powder is compacted under high pressure and sintered in a controlled atmosphere furnace at a temperature below its melting point.

During sintering, the metal particles bond through atomic diffusion, forming a dense structure with controlled porosity. This process enables the manufacture of mechanical parts with complex geometries and tight tolerances.

Its ability to produce near-net-shape components with minimal material waste makes it a cost-effective, high-volume production method.

What are the Main Applications of Sintered Metals?

Sintered metals are widely used in the automotive, industrial machinery, home appliance, aerospace, medical, and filtration industries due to their cost-effective mass production, high material utilization, consistent quality, and high precision.

Automotive:

Sintered metal parts find broad application in automotive engines, transmissions, and braking systems. Common parts include oil pump rotors and gears, camshaft phasers, valve seats, bushings, bearings, timing sprockets and pulleys, water pump flanges, and shock absorber pistons. Powder metallurgy processes enable near-net-shape production, offering cost advantages for high-volume automotive part manufacturing.

Industrial Machinery:

Sintered metal parts such as pulleys, rotors, clutches, and structural components are utilized in mechanical equipment, robotics, and automation systems due to their high dimensional accuracy and wear resistance.

Home Appliances:

Sintered metals are also widely adopted in in home appliances, such as oil impregnated bushings in electric fans, compressor valve plates and discs in refrigerators, and gears in washing machines.

Aerospace:

High-strength sintered alloys and metal-ceramic composites are applied in aircraft turbine components, bearings, and structural parts, where weight reduction and reliability are important.

Medical:

Sintered titanium alloys are ideal for manufacturing surgical instruments, dental implants, and porous orthopedic implants due to their biocompatibility and excellent corrosion resistance.

Filtration and Fluid Control:

Porous sintered structures made from bronze, stainless steel, titanium, and nickel alloys are incorporated into filtration and fluid control systems. Their controlled pore size enables precise filtration, gas diffusion, and pressure balancing.

What is the Sintering Temperature for Sintered Metal Products?

Sintered Iron-Based Parts:

Pre-sintering: 600°C → 720°C → 900°C (45 minutes).

High-temperature sintering: 1120°C (45 minutes).

Cooling: 120 minutes.

Sintered Copper-Based Parts:

Pre-sintering: 500°C → 600°C → 700°C (60 minutes).

High-temperature sintering: 800°C (60 minutes).

Cooling: 120 minutes.

Sintered Stainless Steel Parts:

Pre-sintering: 600°C → 720°C → 900°C (60 minutes).

High-temperature sintering: 1250°C (60 minutes).

Cooling: 120 minutes.

Sintered Copper-Iron Alloy Parts:

Pre-sintering: 500°C → 600°C → 700°C (60 minutes).

High-temperature sintering: 900°C (60 minutes).

Cooling: 120 minutes.

What are the Sintering Atmospheres?

Atmosphere is a key factor in the sintering process, affecting the mechanical properties, appearance and corrosion resistance of your product. Its main functions include:

- Preventing air from entering the furnace to avoid product oxidation.

- Aiding in the removal of binders from the parts.

- Reducing the oxide layer on the surface of the compacted powder.

- Controlling the carbon content of the product.