Powder injection molding is one of the advanced manufacturing techniques that combines the design flexibility of plastic injection molding and the strength of powder metallurgy process. In this technique, the feedstock is basically prepared by mixing metal powder with a plastic binder. PIM is used for manufacturing small, complex-shaped components that require high precision and an excellent surface finish.

For example, it is widely adopted in high-performance industries such as the aerospace and automotive industries for producing satellite connectors and sensor housings, respectively.

Contents

Evolution of Powder Injection Molding

This manufacturing technique was developed in the 1920s to produce components made with ceramics, as ceramics were easily available and reliable. However the metallic version of PIM was adopted in the 1970s by Dr. Raymond E. Wiech Jr., it is now more commonly known as metal injection molding (MIM). This led to the invention of the Wiech process, which made it possible to mix metal powder and plastic binder to manufacture complex components, laying the foundation for modern powder injection molding.

Powder Injection Molding Process

Feedstock Preparation

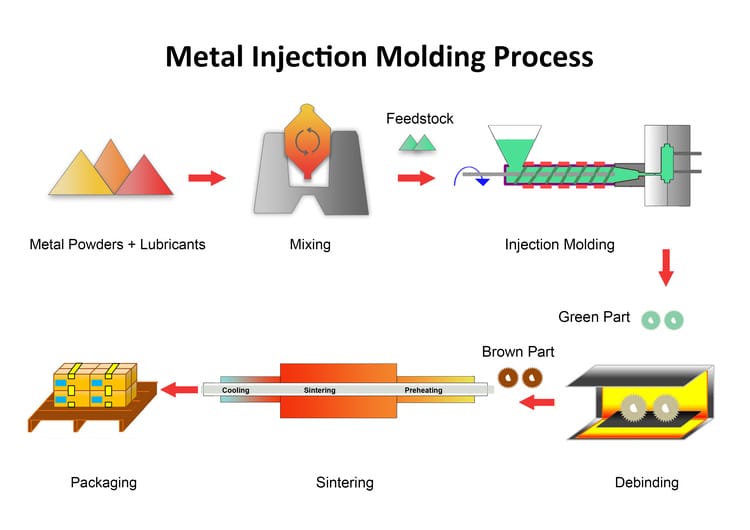

Feedstock preparation is the first major step in your PIM process; the Feedstock is typically prepared by mixing the binder and metal or ceramic powder.

Plastic Binder

Two types of binders are used in feedstock: one of which is the primary binder, which is removed during the debinding step. Whereas the secondary binder provides strength to the green body until sintering is done. Here are some common binders used:

- Polyoxymethylene (POM)

- Polyethylene (PE)

- Paraffin wax (PW)

Powder Used

The powder used in PIM typically features a spherical morphology and a particle size range of 1 to 20 µm. The powder typically accounts for 60–70% by weight of the feedstock, which provides a balance between strength, flowability, and uniform mixing.If the composition increases beyond this range, it can decrease the flowability of the feedstock. Here are the powder material which are used:

- Stainless

- Low alloy and high-speed steels

- Copper

- Nickel,

- Aluminium and cobalt base alloys

- Ceramic materials: Alumina, Zirconate, Silicon carbide, Silicone-nitride,

- Metal matrix composites (MMC)

- Ceramic matrix composites (CMC)

Injection Molding

After the feedstock is prepared, it’s now time to inject the feedstock into the mold to get the desired shaped components. This part is divided into four steps:

Mold Closure

As soon as the injection unit prepares a controlled amount of plasticized feedstock inside the barrel, the mold is closed.

Material Injection

A screw mechanism then injects the molten feedstock into the mold cavities under high pressure. This injection pressure ensures the material flows uniformly and fills complex geometries.

Holding Pressure

When the mold is filled with feedstock to minimize shrinkage, holding pressure is applied to compact the material. This pressure is maintained until the feedstock begins to solidify.

Cooling and Part Extraction

The component is allowed to cool inside the mold with the help of circulating coolant. When it has completely solidified and cooled, the mold is then opened, and the green part is ejected.

Debinding

After the green part is prepared, it’s time for debinding to produce a porous component, which is known as the brown part. It has a porosity of about 40–50% by the original volume of the component. This brown part is further sintered to get the final product. Here are some common ways with the help of which debinding is done:

- Thermal Debinding

- Solvent Debinding

- Catalytic Debinding

Sintering

Sintering process is the last and final step of powder injection molding. Here, the brown part undergoes further densification and converts into a high-strength component. Three fundamental changes occur here in the brown part;

Binder Removal

The brown part is gradually heated to a temperature below the material’s melting point—typically 70–90% of the melting point. For example, 17-4 stainless steel is sintered at 1200–1360°C. The heating takes place under controlled conditions to prevent defects and remove any remaining binder.

Densification

Metal particles begin to diffuse at the atomic level, forming strong bonds at contact points. This reduces pore volume and causes the part to shrink, enhancing its overall strength.

Cooling

The sintered part cools slowly to room temperature. Controlled cooling helps maintain structural stability and prevents cracking or distortion. The final density typically reaches 95% to 99% of the theoretical maximum.

Types of Powder Injection Molding

Based on the powder material us the powder injection molding is divided into two main types here they are:

Metal Injection Molding (MIM)

Powder injection molding, where metallic powder is mixed with a polymer binder, is also known as metal injection molding or metal powder injection molding. This technique is suitable for manufacturing components with tight tolerances and high mechanical strength. Components made using this technique exhibit a theoretical density of up to 98–99%. MIM is considered ideal for high-volume production of small parts (< 100 g).

Ceramic Injection Molding (CIM)

In ceramic injection molding, the ceramic powders are mixed with a thermoplastic binder to prepare the feedstock. This technique is widely used for the manufacturing of high-precision small components with a wall thickness of 0.1 mm and density as high as 99%. CIM is used in electronics, aerospace, and biomedical industries.

Advantages of Powder Injection Molding

Complex Geometry

One of the biggest advantages of PIM is that it enables the production of highly complex, net-shaped components. These components feature intricate design elements, including undercuts, re-entrant angles, multi-shape blind holes, and fine thread geometries.

Material Versatility

Injection molding powder supports a wide range of materials, including metals, ceramics, and composites. It uses fine powder, which enables the formation of both dense and porous structures. As a result, PIM is used in the manufacturing of fuel cells, filters, and medical components.

High Production Efficiency

Components produced with the aid of this technique typically do not require secondary machining. Due to this, the output efficiency of the process increases, making it suitable for large-scale production in industries such as automotive and electronics.

Minimal Waste

The raw material is effectively used in powder injection molding, leading to minimal wastage as the excess feedstock can be reused. Not only this, but the defective parts are also easily recycled.

Consistent Quality

PIM shows high control over part density and microstructure, resulting in repeatable mechanical and thermal properties.

Limitations of Powder Injection Molding

High Costs

Although powder injection molding enables the manufacturing of high-precision components with near-net-shaped geometries, it is quite costly. This is due to the high cost of raw material and the specialized equipment used in the process.

Binder Removal Complexity

Debinding requires precise control to avoid part defects, making the process time-consuming and sensitive.

Part Size and Feature Limits

PIM is ideal for small, intricate parts; producing large or thick-walled components may lead to inconsistent density and defects.

Applications of Powder Injection Molding

Medical Industry

PIM is used in medical industry for production of various equipments such as:

- Orthodontic brackets: These are designed with high-strength and miniaturized for precision dental alignment

- Surgical instruments: These tools have complex geometries and require corrosion resistance, which is achieved by manufacturing them using powder injection molding.

Automotive Sector

Powder injection molding is widely adopted in the automotive industry due to its ability to produce complex, high-strength parts for demanding environments:

- Fuel injector parts: These parts require high tolerances and excellent wear resistance.

- Turbocharger components: These are made from heat-resistant metal powders.

- Gearbox parts and actuator housings: They require dimensional accuracy and fatigue resistance

Electronics Industry

You know that miniaturization and precision are critical in electronics, and powder injection molding offers unparalleled advantages:

- Micro connectors and socket housings with compact designs, high mechanical and electrical performance

- Mobile device hinges and buttons

Aerospace Industry

It supports the aerospace sector with components that meet weight and performance criteria:

- Turbine blades and stator parts

- Fuel nozzle components

- Satellite connectors and structural fasteners

Consumer Goods

PIM provides design freedom for high-quality and durable components in consumer products:

- Watch cases and knife blades

- Eyewear components and harmonica reeds

- Appliance parts and luxury pens

BLUE is a dedicated powder metallurgy company, supplying metal injection molding products and sintered ceramics. We supply a full range of standard parts without tooling fees, available for direct comparison and selection in our SHOP. We also provide custom services to meet your specific design, performance, or dimensional requirements.