In the world of materials science and metallurgy, Vickers Hardness Test is one of the processes used to determine material hardness. Hardness testing generally aids engineers in assessing the strength, durability, and wear resistance of a material. Among the numerous hardness testing methods available, Vickers stands out because it is accurate, versatile, and capable when it comes to very small and thin samples.

As we progress, you’ll learn more about the principle, procedure, pros, cons, and practical uses of the Vickers method in engineering and other industries.

Contents

What Is Vickers Hardness Test?

In 1921, the Vickers Hardness Test was developed by Robert L. Smith and George E. Sandland at Vickers Ltd. The test measures the hardness of materials using a pyramid-shaped diamond indenter through an optical method.

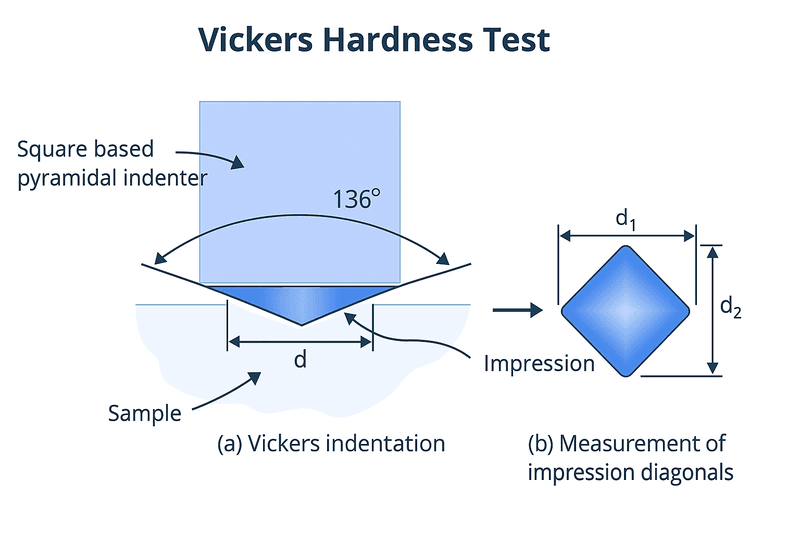

The Vickers Hardness Test is a microhardness testing method that ascertains the level at which a material is resistant to plastic deformation from a standard source. It is one of the oldest testing methods used and very common in the UK and Europe. The indenter used is diamond-shaped with a square base, and the opposite faces have an angle of 136° between them. This indenter is applied onto the surface of the test material with force from a load, which ranges from a few grams to 100 kgf.

The method is versatile because several tests can be done with the same indenter, just by applying different loads. The Vickers test follows standards such as ASTM E384 or ISO 6507, and can be very useful for comparative studies.

Principle of the Vickers Hardness Test

The Vickers Hardness Test depends on the relationship between the force applied by the load, and the surface area of the indentation made by the indenter. The load is applied for a standard period of about 10 to 15 seconds, and the two diagonals of the indentation created are measured using a microscope. These values are used to calculate the Vickers Hardness Number symbolized as VHN or HV. The hardness of a material can also be expressed in terms of the load used, for example, HV5 means the hardness calculated for a 5kg load.

How to Measure Vickers Hardness

Sample Preparation

The test sample to be used must meet certain specifications in order to avoid making mistakes during the test. First, the surface of the test material should be smooth and properly polished. Next, it must be flat so when the load is applied, the indentation made by the indenter can be measured easily.

Machine Setup

The Vickers hardness tester is calibrated properly for the testing process to be carried out without errors by ensuring that all components are set according to the ASTM and ISO standards. For example, the load applied ranges between 1 gf to 120 kgf, which depends on the material being tested.

Load Application

The indenter is used to apply the load to the test sample for a dwell time of about 10 to 15 seconds. This process can either be done automatically, or manually, depending on the capacity of the Vickers hardness machine used.

Measurement

After the load is removed when the dwell time is completed, the measurement to be taken is that of the diagonals of the indentation. This is measured using a microscope, and must be done carefully to avoid errors in calculations. The average of the diagonal measurements is taken to get the single value to be used in the Vickers hardness test formula.

Calculations and Results

Calculating the hardness of the material is straightforward using the above mentioned formula, and the Vickers hardness is expressed in this form xxxHVyy or xxxHVyy/zz. Where xxx stands for the Vickers hardness number, yy is the load, and zz is if the dwell time is beyond the approved standard of 10 to 15 seconds. For example, 400HV10 or 400HV10/20 means that the material has a Vickers hardness number of 400 kgfmm-2, where a load of 10 kgf was applied, for a dwell time of 20 seconds.

Applications of Vickers Hardness Test

The Vickers method is highly versatile and used across multiple industries, including:

- Metallurgy: Testing grain boundaries, phase changes, and zones treated with heat..

- Aerospace & Automotive: Evaluating coatings, alloys, and fatigue resistance.

- Electronics: Measuring hardness of solder joints and micro-components.

- Quality Control: Inspecting manufactured parts and weld zones.

- Research & Development: Studying new materials, microstructures, and composites.

Advantages of the Vickers Hardness Test

- Wide Load Range: Effective for both micro and macro hardness testing.

- Material Versatility: Can be used on metals, ceramics, and polymers.

- Precision: High accuracy with minimal variation.

- One-Scale System: Simplifies comparisons across different materials.

- Minimal Sample Damage: Indentations are small and shallow.

Limitations of the Vickers Test

- Time-Consuming: Requires optical measurement and calculation.

- Surface Preparation Sensitivity: Rough or curved surfaces can lead to inaccurate readings.

Comparison with Other Hardness Tests

The table below outlines the key differences between Vickers, Brinell, and Rockwell hardness testing methods.

| Feature | Vickers | Brinell | Rockwell |

|---|---|---|---|

| Indenter | Diamond pyramid | Steel/carbide ball | Steel/dome/varied shapes |

| Load Range | 1 gf – 120 kgf | 500 kgf – 3000 kgf | 15 kgf – 150 kgf |

| Precision | High (optical) | Medium (optical) | High (depth-based) |

| Surface Prep Sensitivity | High | Medium | Low |

| Applications | Micro components, coatings | Castings, forgings | Mass production parts |

Among all hardness testing methods, the Vickers test is preferred for sintered metal due to its precision and adaptability. It uses a diamond-shaped indenter and supports a wide range of loads. According to Struers, commonly used loads such as HV5, HV10, and HV20 are suitable for testing medium- to high-hardness sintered metal parts. This allows for accurate measurement of the matrix hardness while minimizing errors caused by surface porosity.

FAQ

Does the Shape and Material of The Indenter Affect the Accuracy of The Vickers Hardness Test?

Yes it does. The indentation made by using the indenter must have a properly defined shape to be able to be measured. Additionally, the indenter has to be made of a material that is resistant to deformation in itself, else the measurements will be erroneous. That is why diamonds are a good fit.

Does the Size of The Indentation Affect the Vickers Hardness Level of A Material?

Yes, the Vickers hardness rating of a material is inversely proportional to the indentation size. This means that the smaller the size of indentation, the higher the hardness rating of the test material the indentation was made on.

Is The Indentation Damage Made During Vickers Test A Contributing Factor to Analyzing The Tested Material?

Yes, during indentation, cracks appear at the four corners, and these cracks can also play a role in further tests that analyze the quality of the material.