Stainless steel powder is a finely divided form of stainless steel metal, usually consisting of iron, nickel and a minimum of 10.5% chromium. The presence of chromium imparts exceptional properties to this powder, such as wear and corrosion resistance. As a result, it is widely used for manufacturing different components in various industries, from additive manufacturing and powder metallurgy to automotive, aerospace, and medical applications.

Contents

Stainless Steel Powder Production Methods

The following are common stainless steel powder production methods: gas atomization, water atomization, and plasma atomization.

Gas Atomization

Gas atomized stainless steel powder is highly spherical which is manufactured and produced by atomizing molten metal with high-pressure Inert gas. The particle size of powder typically ranges from 15–to 45 microns, possessing the following properties:

- Tight particle size distribution

- Excellent flowability

- Superior spreadability

All of these properties of powder combined make it ideal for its use in additive manufacturing, such as in SLM and EBM.

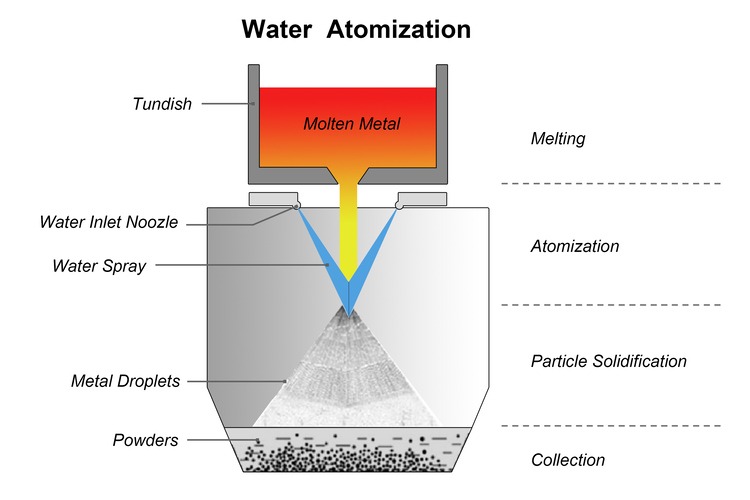

Water Atomization

This stainless steel powder is produced by spraying molten steel with high-pressure water jets. The metal powder produced in this method has irregular particle shapes. Here, the particle size distribution is generally wider, with sizes reaching up to 100 microns. Stainless steel powder shows lower flowability and packing density as compared to powder produced in the Gas automaton. Water-atomized powders are widely used in press-and-sinter applications for manufacturing of components in the automotive and aerospace industry.

Plasma Atomization

In plasma atomization, a wire or rod of stainless steel is melted by a plasma arc and atomized into powder. This technique produces metal powder with the following:

- Highly spherical particles

- Size range of 15–45 microns

- Exceptional flowability

- High sphericity enables

- High packing densities

Plasma atomized powder is used where the production of parts with fine features and smoother surface finishes is required. It is commonly applied in high-end additive manufacturing techniques.

Different Grades of Stainless Steel powder

Austenitic Stainless Steel Powder:

Austenitic stainless steels powder have the greatest corrosion resistance, good weldability and non-magnetic. 304 and 316 grade stainless steel powders are suitable for highly corrosive applications. 303 stainless steel powder is easy to process and 310 grade is used as a refractory material.

This category typically includes grades like 3.3L, 304L and 316L.

Composition of Austenitic stainless steel powder

| Grade | Cr (%) | Ni (%) | Mo (%) | Mn (%) | Si (%) | S (%) | P (%) | C (%) |

|---|---|---|---|---|---|---|---|---|

| 303L stainless steel powder | 17 – 19 | 8 – 13 | – | 0 – 2.0 | 0 – 1.0 | 0.15 – 0.3 | 0 – 0.20 | 0 – 0.03 |

| 304L stainless steel powder | 18 – 20 | 8 – 12 | – | 0 – 2.0 | 0 – 1.0 | 0 – 0.03 | 0 – 0.04 | 0 – 0.03 |

| 316L stainless steel powder | 16 – 18 | 10 – 14 | 2 – 3 | 0 – 2.0 | 0 – 1.0 | 0 – 0.03 | 0 – 0.04 | 0 – 0.03 |

Ferritic Stainless Steel Powder

Ferritic stainless steel is known for its magnetic and high resistance to corrosion and cracking under stress. These metal powders, including 404, 410L and 434L, are mostly used for manufacturing automotive components and industrial equipment.

Composition of Ferritic Stainless Steel Powder:

| Grade | Cr (%) | Mo (%) | Mn (%) | Si (%) | S (%) | P (%) | C (%) |

|---|---|---|---|---|---|---|---|

| 410L stainless steel | 11.5 – 13.5 | – | 0 – 1.0 | 0 – 1.0 | 0 – 0.03 | 0 – 0.04 | 0 – 0.03 |

| 430L stainless steel | 16.0 – 18.0 | – | 0 – 1.0 | 0 – 1.0 | 0 – 0.03 | 0 – 0.04 | 0 – 0.03 |

| 434L / CB stainless steel | 16.0 – 18.0 | 0.75 – 1.25 | 0 – 1.0 | 0 – 1.0 | 0 – 0.03 | 0 – 0.04 | 0 – 0.03 |

Duplex Stainless Steel Powder

Duplex stainless steels show the properties of both austenitic and ferritic stainless steels. Due to their remarkable corrosion resistance, high strength, and superior performance, they are considered ideal for an aggressive environment. These powders are used in the oil and gas industry, marine applications, and chemical processing equipment.

Properties of Stainless Steel powder

Stainless steel powder shows excellent properties compared to traditional carbon-based steel due to the presence of nickel and chromium. Here are its remarkable properties:

Corrosion Resistance Properties:

Corrosion and Wear Resistance Properties of Stainless Steel Powder

Pitting Resistance

Stainless steel powders offer strong resistance to pitting corrosion, which makes them suitable for applications where small surface defects could lead to rapid material failure.

Crevice Resistance

The powders also show good crevice corrosion resistance, which allows components to perform well even in tight, stagnant areas where oxygen may be limited.

Stress Cracking Resistance

Stainless steel powders exhibit excellent resistance to stress corrosion cracking (SCC). It is critical for structural and pressure-bearing parts.

Wear/Erosion Resistance

Due to their high hardness and tough microstructure, stainless steel powders are also wear and erosion-resistant. This property makes them ideal for applications involving abrasion, impact, or high-velocity fluid flow.

Oxidation Resistance

High-quality stainless steel powders can withstand oxidizing conditions at elevated temperatures up to around 900°C.

Mechanical Properties

| Property | Property | ||

|---|---|---|---|

| Yield Strength | 100–350 MPa | Hardness (Brinell) | 160–240 |

| Ductility (Elongation) | 10–50% | Fracture Toughness | 20–200 MPa |

| Impact Resistance | Good | Magnetic Behavior | Non-magnetic grades available |

Thermal Properties

| Property | Property | ||

|---|---|---|---|

| Tap Density | 5.0 g/cm³ | Thermal Conductivity | 12–30 W/m·K |

| Melting Point | 1300–1500 °C | Curie Temperature | –150 °C to 315 °C |

Stainless Steel Powder Supplier

Höganäs

Höganäs is globally known as one of the finest metal powder suppliers across the world, with more than 3000 customers across 75 countries since 1797, they have been delivering excellence. Höganäs provides a wide range of metal powders, including high-performance stainless steel powders. Their meta powder is used for applications in additive manufacturing, surface coating, and traditional powder metallurgy industries.

Rio Tinto Metal Powders

Founded in 1968 as Quebec Metal Powders. It has evolved into a global leader in the production of clean, high-quality ferrous powders. The company uses high-purity iron from Rio Tinto Iron and Titanium (RTIT) to produce single-source powder. These powders are ideal for press-and-sinter, additive manufacturing, and energy storage applications..

Factors Affecting the Cost of Stainless Steel Powder

Raw Material Costs

The primary alloying element affects the price of stainless steel powder. The presence of nickel is a major cost driver.

Production Method

The method used to produce the powder significantly impacts cost, such as gas atomized powder is generally more expensive than water-atomized powder.

Particle Size and Distribution

Finer powders with narrow size distributions cost more due to additional classification, sieving, and quality control processes.

Volume and Batch Size

Small batch production typically results in higher costs per kilogram, whereas bulk purchasing generally reduces unit price due to economies of scale.

Market Demand and Supply Fluctuations

Global supply chain dynamics, demand from industries such as aerospace, automotive, and energy sectors, and geopolitical factors can cause volatility in the price of stainless steel powder.

Uses of Stainless Steel Powder

Powder Metallurgy (PM)

In the powder metallurgy industry, stainless steel is also a common raw material because of its good corrosion resistance and high temperature resistance. Common sintered stainless steel parts are: flanges, valve guides, chain bushings, locks, plumbing fittings gears, cams, connecting rods

Metal Injection Molding (MIM)

Stainless steel metal powder is also used In metal injection molding. Here, metal powder is mixed with a polymer binder to create components with high precision.

3D Printing

Stainless steel powders are essential for 3D printing technologies such as SLM, DMLS, and binder jetting. These powders enable the production of highly complex geometries and lightweight structures.

Surface Coating and Thermal Spraying

Fine stainless steel powder coatings are used in thermal spray coatings to provide surfaces with corrosion resistance.

FAQ

1. How to Choose the Stainless Steel Powder?

Select based on your application requirements, needed mechanical properties, required particle size, shape, purity and production method.

2. What Post-processing is Needed after 3D Printing with 316L Stainless Steel Powder?

After printing, thermal treatment is typically carried out to reduce internal stress. It also helps in improvig structural stability. Not only this some time hot isostatic pressing is also done depending on the required density and mechanical strength.