Metal components can be manufactured using multiple techniques. Every technique has its pros and cons and a different method of processing.

The decision of which method to choose depends upon the nature of the components and what features a particular process offers. Powder metallurgy and stamping are two commonly used methods for manufacturing metal components.

These two processes are different from one another and have their pros and cons, which make them different. In this blog, I will provide you with an in-depth comparison of powder metallurgy vs. stamping.

Contents

What is Powder Metallurgy?

Powder metallurgy, as the name suggests, uses metal powders for manufacturing metal components. In this process, a die is used in which metal powders are compacted and then subjected to high temperature for the sintering stage, which turns the powdered metal into solid ones.

The process of powder metallurgy comprises multiple advantages and some disadvantages too, and some of these have been discussed below:

Advantages of Powder Metallurgy

Powder metallurgy industry has the advantages of high design flexibility, tight tolerances, and cost-effective mass production.

Flexible Design Options

Powder metallurgy can manufacture multi-step parts, gears, pulleys with high precision without secondary processing, which is difficult for stamping process.

Wide Materials Choice

Powder metallurgy uses many kinds of materials, which may comprise steel alloys and stainless steels. Even the components can be reinforced using carbon fibres and ceramic during manufacturing.

Material Efficiency

The material utilization efficiency of powder metallurgy is as high as over 95%, with less waste, which helps save raw material costs.

Tight Tolerances

Sintered parts have good radial dimensional tolerances, typically ranging from IT7 to IT9. After the sizing process, tolerances of IT5 to IT7 can be achieved.

Disadvantages of Powder Metallurgy

Tooling Fee

Powder metallurgy toolings are usually more expensive because they have high precision and needs to withstand high pressure and abrasion from metal powder.

Porosity

Sintered metal parts contain pores inside, and manufacturers usually need to perform surface treatment to prevent rust and increase density, hardness, etc.

Initial Investment

Powder metallurgy process requires a range of equipment, including a powder mixer, powder compaction press, sintering furnace, surface treatment equipment, sizing press, and more. This may necessitates a relatively large initial investment.

What is Stamping?

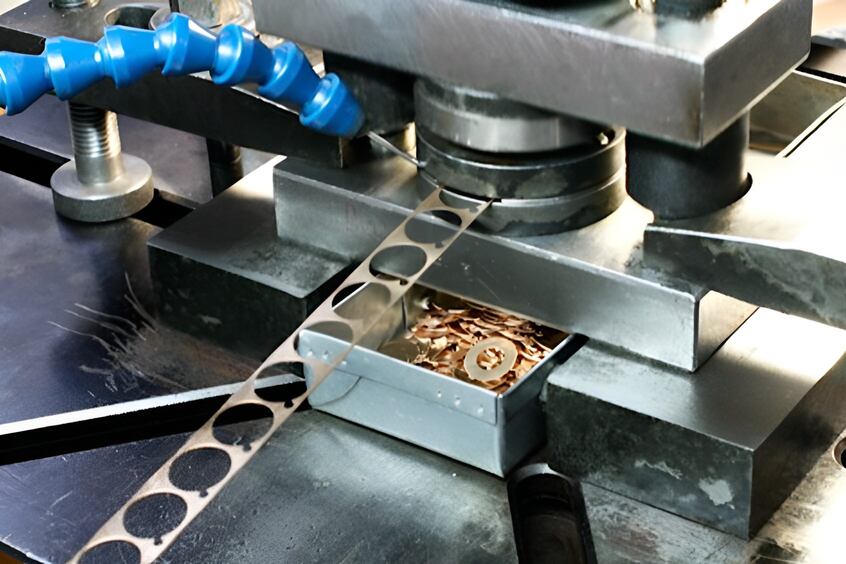

Stamping is a manufacturing process that shapes and metal sheets or strips into specific forms using a press and a die.

These sheets are pressed on a die, comprising many stages like bending, cutting, and forming.

Advantages of Stamping

The stamping process has the following advantages:

Wide Range of Materials

Stamping has a wide range of metal material options, including; aluminum, copper, brass, steel, stainless steel, nickel, etc.

Good Surface Finish

In most cases, the surface finishing of the components manufactured using stamping is excellent; hence, no additional processes are needed.

Cost-Effective

Stamping manufacturing process is suitable for producing high volumes at a low cost; hence choosing it helps save money.

High Precision

Stamping is suitable for manufacturing components with tight tolerance and hence offers highly precise parts.

Disadvantages of Stamping

Although the stamping process has the advantages of high production efficiency, good surface finish and high precision, it also has some disadvantages.

Material Waste

Stamping is a subtractive manufacturing process, and the material utilization rate is not high.

Low Design Flexibility

Stamping process is primarily suited for flat metal sheets, so the process may not be ideal for producing parts with complex geometries.

When these two processes are compared, both have pros and cons, now depending upon the application and the process that can be chosen.

On the other hand, powder metallurgy is a near net shape manufacturing process with unique advantages like less raw materials waste and higher design flexibility. At the same time, stamping is suitable for high-volume production in less time.

The decision to choose the process depends upon the production volume, complexity, and size of the part manufactured.