Powder Metallurgy Gear in China

Powder metallurgy gears from BLUE are precision-pressed into exact sizes and shapes by our advanced powder compaction press, reducing the need for secondary machining. We have the capability to manufacture a wide variety of sintered gears, including spur gears, helical gears, bevel gears, double gears and planetary gears.

What is Powder Metallurgy Gear?

The powder metallurgy gear is a fine high-precision gear which is formed by compacting the metal powders, such as iron powder, steel and bronze etc., to the mould made of mateal powders and sintered at constant temperature after having been compacted. The process produces close-to-net shape parts having uniform density and precise dimensions, which substantially decreases the amount of post-processing that is required.

Powder metal gears possess high volume material utilization, uniform microstructure and controlled porosity for oil soaking/sweeping to achieve a self-lubrication. They offer wear resistance and quiet, low-vibration operation for automotive transmissions, oil pumps, power tools, and industrial equipment

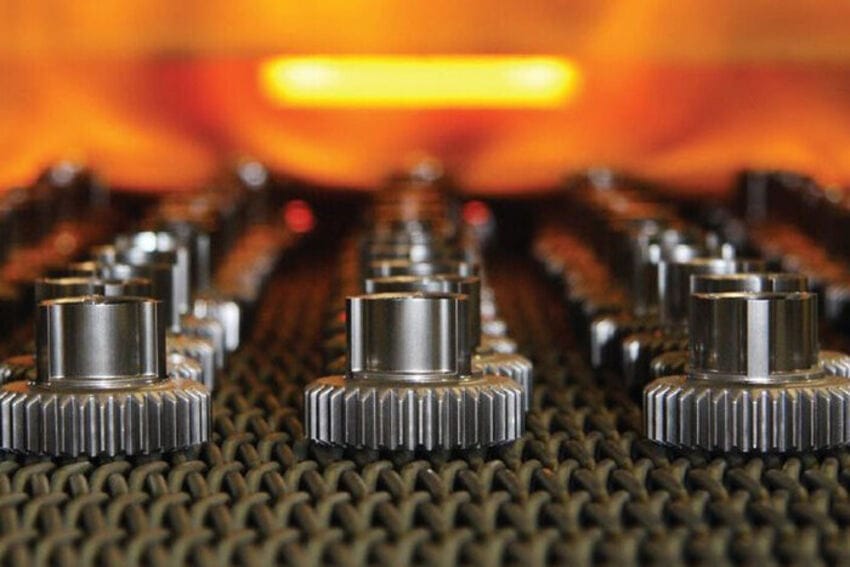

Powder Metal Gear Manufacturing Process

The process of manufacturing powder metal gears includes compressing metal powders within accurate die and sintering them in a controlled manner to establish complete metallurgical bond.

Metal powder, such as iron, steel or bronze powder is mixed with alloy ingredients and lubricants to achieve consistent density and fluidity. In compautlon the powder matertal Is compacted under high pressure to a green gear blank of precise geometry. The sintering step then heats the compact to approximately 1120–1250 °C in a controlled atmosphere, and diffusion of atoms between particles causes the solid to form a dense sintered body with high mechanical strength and good dimensional stability.

Post-sintering optional operations, such as sizing, heat treatment, grinding, and oil impregnation maximize precision quality, hardness and lubrication performance. The result is a precision gear with durability and performance in some of the tightest tolerances available.

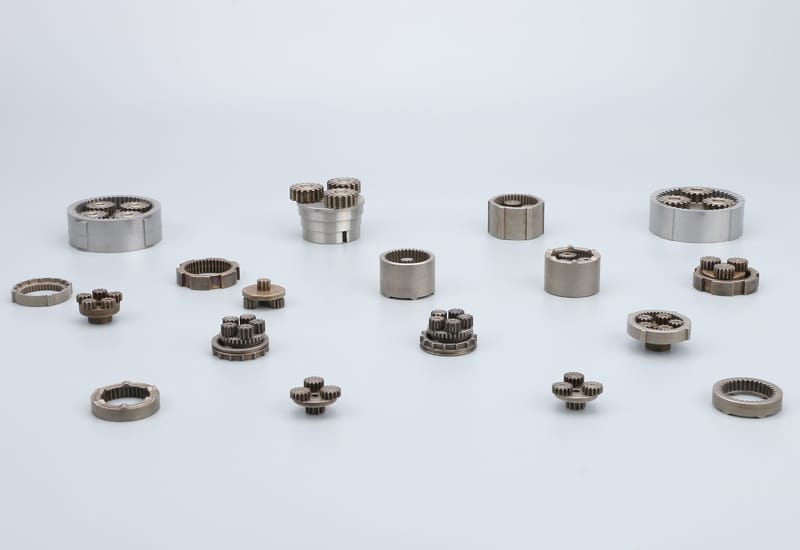

Powder Metallurgy Gears Manufactured by BLUE

Here are various powder metallurgy gears we have manufactured, including spur gears, helical gears, bevel gears, oil pump gears, double gears, and planetary gears.

Sintered Gears

Sintered gears are formed by pressing metal powder in one step, without the need for secondary processing.

Sintered Metal Gears

Sintered metal gears require heat treatment process, and the surface hardness can reach above HRC50.

OEM Sintered Gears

OEM sintered gears use metal powder as raw material, and the material utilization rate can reach more than 95%.

Powdered Metal Bevel Gears

Powder metal bevel gears have a conical shape and transmit rotational motion between intersecting shafts at an angle.

Powdered Metal Spur Gears

Powdered metal spur gears transmit motion and power between parallel shafts. They are easily pressed into precision shape.

Powder Metal Helical Gears

Powdered metal helical gears feature teeth that are angled (helix) with the gear axis, which allows for smooth, quiet operation.

Factory Sintering Gears

The quality of powder metallurgy gears produced by Chinese factories is already quite high, comparable to your local suppliers.

Sintered Powder Metal Gears

Sintered powder metal gears allow for flexible material composition adjustments to meet the performance requirements of various parts.

Oil Pump Gears

An oil pump gear is a key component in oil pump that pressurize and circulate oil throughout an engine's lubrication system.

Why Choose Us?

BLUE is your trusted manufacturer of high-quality powder metallurgy gears, providing strict quality control, free mold design, fast delivery, and competitive price from China.

BLUE High Quality Standards

BLUE assures your product quality with ISO 9001:2015 certified quality management system. We provide a one-year warranty on your powder metal gears.

Standard Sintered Gears Shop

We have a wide range of standard sintered metal gears in stock for quick delivery. All of these sintered metal gears come with no mold fees.

Download Sintered Gears Product List

Discover BLUE’s full range of powder metallurgy standard sintered gears. Download our free product list to find the exact match for your requirements.

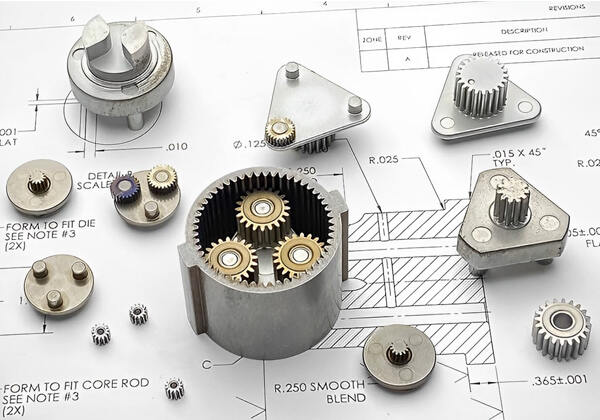

BLUE's Custom Powder Metal Gears Specifications

BLUE’s ability include but are not limited to:

Diameter: 5mm to 250mm is available.

Height: 5 to 100mm is possible.

Geometries: multi-step, helical, bevel, flanged gears are all available.

Helical gears up to a 20 degree helix angle.

All BLUE’s sintered cylindrical gears can reach DIN 3961 grade 8.

After heat treatment, the surface hardness of our sintered gears can reach 560~660 HV10(HRC 53~58).

We can improve the tooth surface accuracy of sintered gears by honing technology

Powder Metallurgy Gear Design Advices

- Uniform wall thickness:

Design sintered gears with uniform wall thickness to ensure uniform density distribution during pressing and sintering

- Thickness variation:

Multi-link gears should avoid sharp changes in cross-sectional thickness

- Weight reduction holes

When the outer diameter of the gear is large and weight reduction is required, circular weight reduction holes are better and easier to process and install

- Tooth shape

The root and tip edges of involute gears are optimized with rounded transition arcs, which improve root strength and reduce operational noise.

Powder Metallurgy Gear Materials

Our team not only has a deep understanding of powder metallurgy gear manufacturing, but also has extensive expertise in PM materials.

Common materials for powder metallurgy gears include MPIF FN-0205, FD-0205, FN-0205-80HT, as well as JIS SMF5030 and SMF5040.

When powder metal gears face impact loads, the gear teeth are prone to breakage. To address this, materials with better toughness, such as carburized and quenched low-carbon steel, should be used.

For high-speed closed transmission gears, high tooth surface hardness is essential. Medium carbon steel with surface quenching is a suitable choice.

When compact structure and high wear resistance are required for sintered gears, alloy steel is the preferred option.

Mechanical Properties of Sintered Gear Materials

The following are some commonly used mechanical properties of powder metallurgy gear materials.

Model | State | Density g/cm3 | TS Mpa | FL Mpa | Apparent Hardness |

FC-0208 | Sintered Hardened | 6.7 6.8 | 410 620 | 160 240 | 73HRB 35HRC |

FN-0205 | Sintered Hardened | 6.9 6.9 | 340 830 | 120 240 | 59HRB 29HRC |

FX-2008 | Sintered Hardened | 7.3 7.3 | 550 690 | 160 190 | 90HRB 36HRC |

FD-0205 | Sintered Hardened | 7.1 7.1 | 610 1030 | 220 450 | 80HRB 38HRC |

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

Yes. Powder metallurgy gears made with advanced PM technology can be used in high-stress applications. Traditional PM gears have lower density, but through high-density compaction, precision sintering, and heat treatment or powder forging, PM gears can meet high-load requirements.

Powder metallurgy process makes gears by mixing metal powders with binders and alloying elements. The mixture is pressed in a precision die to form a green gear. It is then sintered in a controlled atmosphere to bond the particles.

This process gives high accuracy and good material use. Secondary operations like sizing, heat treatment, or steam treatment can improve precision strength and durability.

Common materials used in powder metallurgy gears include iron-based alloys, stainless steel, and copper alloys. The specific material choice depends on strength, wear resistance, and the environment.

Iron and Steel alloys include carbon steel for basic strength, nickel, molybdenum, or chromium alloyed steels for increased toughness and hardness, and iron-nickel alloys for good impact resistance and heat resistance. These materials dominate gear production due to their balance of cost and performance.

Copper alloys, primarily brass and bronze, are favored for their low friction, self-lubrication, and corrosion resistance, making them ideal for quiet or lightly loaded gears.

Other alloys: Aluminum and titanium are used to manufacture lightweight, corrosion-resistant, or high-performance gears in aerospace, precision, and medical applications.

Powder metallurgy gears offer several key advantages over traditional machined or cast gears.

Near Net Shape Production:

Powder metallurgy process produces gears very close to their final dimensions, greatly reducing or even eliminating the need for machining.

High Material Utilization:

With a material utilization rate above 95%, powder metallurgy significantly reduces waste compared to conventional machining.

Cost-Effective Mass Production:

The high automation and streamlined workflow reduce both labor and processing costs in mass gear production.

High Quality Consistency:

Since every stage—from powder mixing to pressing and sintering—is precisely controlled, powder metallurgy ensures uniform quality and performance from batch to batch.