As widely recognized, powder metallurgy (PM) is an excellent way to quickly produce complex small parts.

But for larger or stronger parts, which process is better?

Forging is a good choice.

Here, we will give you a detailed comparison of powder metal parts vs. forged parts.

Contents

Powder Metal Parts

Explain Powder Metallurgy Process

Powder metallurgy process, as the name suggests, uses metal in the form of a powder. The process used multiple stages of production which include mixing, compacting, and sintering as its main stages.

PM manufacturers create parts through the different powder metallurgy processes:

- Compacting & sintering

- Cold Isostatic Pressing (CIP)

Metal powders are compacted uniformly in all directions using high-pressure fluid in a flexible mold at room temperature.

- Hot Isostatic Pressing (HIP)

This process combines compacting and sintering metal powders simultaneously in a high-pressure, high-temperature environment using inert gas.

Fine metal powders are mixed with a binder, injected into a mold, then debinded and sintered to form high-density parts.

Rolling mills compress metal powders into sheets or strips before the sintering process.

- Powder Extrusion

Billets formed from compacted metal powders are extruded through a die to create components with uniform cross-sections.

- Spark Plasma Sintering (SPS)

Pulsed electric current and pressure rapidly sinter metal powders, resulting in high-density materials.

Pros of Powder Metal Parts

- Quality

Powder metal parts have better quality and fewer defects.

These parts have high product consistency because uniform metal powder is mixed during blending process.

- Unit cost

Powder metal parts have low cost per unit, mainly for the 2 reasons:

- Fully automatic production reduces labor costs

- Using metal powder as raw material, there is little material waste

- Design flexibility

Metal powder forming is easier than other processes. Therefore, PM has high design flexibility in producing parts with complex shapes and intricate features.

- Material utilization

Powder metallurgy has a high material utilization rate. Defective parts after molding can be turned into metal powder for reuse.

Cons of Powder Metal Parts

High Cost of Raw Materials

Metal powders used in PM usually cost more than bulk metals. Because producing fine, high-purity powders requires complex processes.

Tolling cost

PM tooling requires high precision and complexity, leading to higher costs.

Parts size

Compared to forged components, powder metal components are smaller due to the limitations of compaction and sintering equipment.

Porosity problems

Powder metallurgy components can exhibit porosity, which affects their density, strength, and overall mechanical properties.

Mechanical Properties

Generally, powder metallurgy parts have lower ductility and impact strength compared to wrought or forging parts. Therefore, they are not well for products with higher strength requirements.

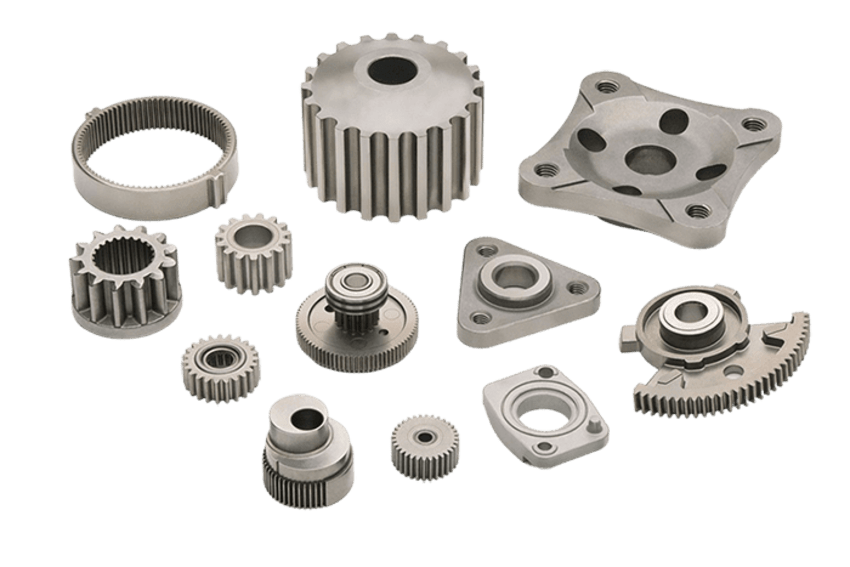

Forged Parts

Definition of Forging

Forging is an ancient manufacturing process that shapes components by hammering, pressing, or rolling metal.

As early as the Warring States Period in China, people used forging technology to produce weapons.

Most forging processes utilize dies to shape and form the metal, especially those that require precise and complex shapes.

Different Types of Forging Process

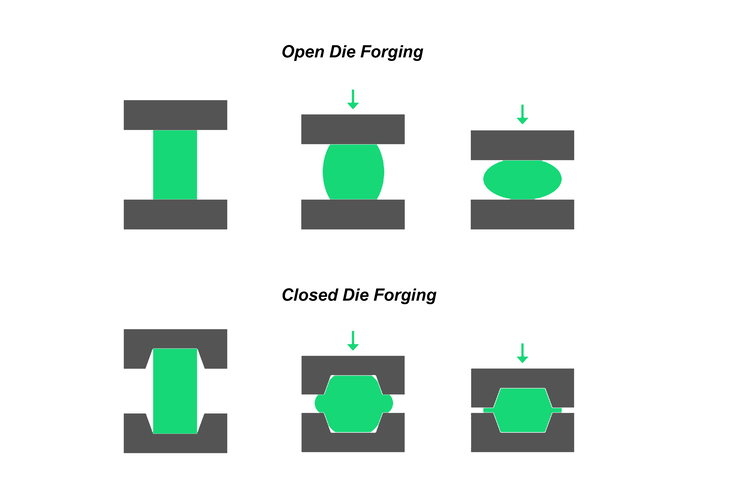

- Open die forging is a process of placing metal between multiple open dies and hammering to produce parts. It is suitable for simple large parts, such as disks, shafts, and cylinders. Since the formed parts are not accurate in size, further processing is required.

- Closed die forging uses high pressure to press metal into a closed die cavity. Compared with open die forging, it is more suitable for smaller parts with higher precision requirements.

- Roll forging is a process that passes a metal part through a pair of rotating rolls to reduce its thickness and increase its length. It has strong continuous processing capability and high efficiency. It is suitable for manufacturing automobile axles and railway tracks, etc.

- Cold forging passes work pieces through multiple dies or multiple impacts to achieve the proper shape. It occurs at room temperature or below the austenite temperature of the metal.

Besides, it is an efficient and economical metal manufacturing process that can be used to produce a large number of parts at low cost.

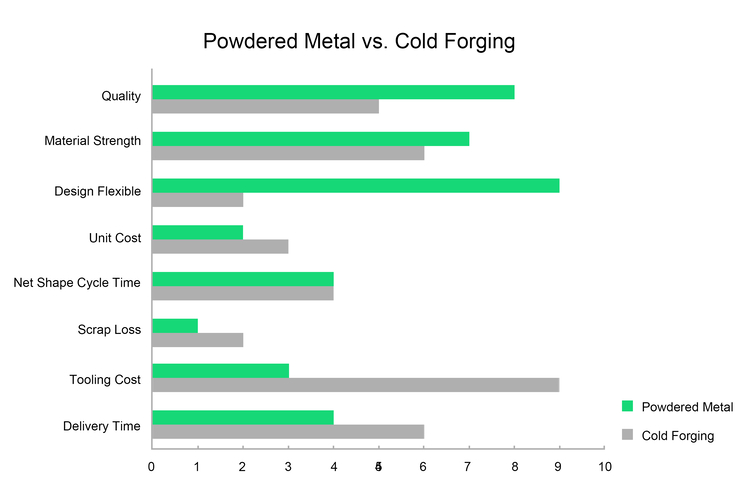

Below is a comparison of powder metal parts vs. forged parts.

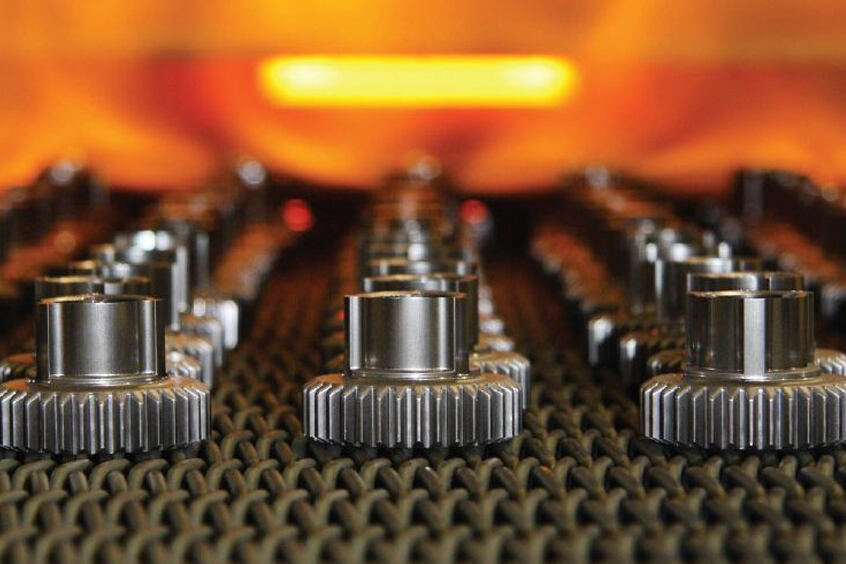

- Hot forging generally heats metal work pieces to a temperature above its recrystallization point but below its melting point. The advantage of hot forging is that the metal flows easily and less processing force is required.

- Isothermal forging is a special hot forging process where both work pieces and the dies are kept at a consistent high temperature throughout the operation.

This technique is ideal for forging difficult materials and achieving precise tolerances.

Pros and Cons of Forged Parts

Pros

Quality

Forged components possess exceptional tensile strength. According to the University of Toledo, the tensile strength of parts produced by forging is 26% higher than those produced by casting. Besides, forged parts exhibit high ductility and respond better to heat treatment compared to parts produced by other process.

Fatigue strength

Other metal manufacturing methods cut grain flow lines, while the forging process maintains grain flow. Therefore, forging parts have higher resistance to fatigue. This improves the service life of the product.

Production speed

Forging requires only one or a few presses to quickly produce the final part geometry. So the production efficiency is relatively high.

Tooling cost

Compared with powder metallurgy, the die used in forging is relatively simple and cheaper.

Material utilization

Waste is a major problem in metal manufacturing. This is rarely the case with forging. The burrs and scraps left over from the forging process can be recycled.

Cons

Shape Complexity Limitations

Forged parts are typically machined into simple shapes.

Need second processing

Many forgings require additional machining and finishing processes to achieve the final dimensions and surface finish.

Environment problem

Some forging processes require high temperatures, and fuel combustion may produce harmful gases and pollute the environment.

Which Process is Suitable for Your Projects?

There must be a question about which process most suitable for your projects. Well, the answer to this is that it depends on the project.

Selecting between powder metallurgy (PM) and forging depends on various factors such as:

- Desired properties of parts

- Cost considerations

- Production volume

- Specific application requirements

If the product size is large and the strength and fatigue resistance requirements are good, you can give priority to forging.

For complex shapes and high-volume production, powder metallurgy is likely the better option. Powder metal parts generally have the advantage of being closer to net shape than forged parts.

FAQ

1. How Long does it Take for Sample and Mass Production of Forging Process?

Generally, it takes about two to three weeks to produce forging dies and samples, and about one month for mass production.

2. What is the White Powder Used in Forging?

The white powder used in the forging process refers to forge flux. Flux is a mixture of borax, silica, and iron oxide, typically ground into fine powder for use.

Flux powder helps remove impurities and oxides from the surface of the molten metal.