Metal Injection Molding Services

With BLUE’s metal injection molding services, you can produce small, precise components with complex geometries. We are capable of producing MIM parts ranging from 0.2 g to 300 g in weight, with diameters between 2 mm and 150 mm.

Why Choose BLUE?

BLUE delivers high-quality metal injection products, supported by advanced production machines, strict quality control, and free mold design—your trusted choice!

BLUE High Quality Standards

BLUE assures your product quality with ISO 9001:2015 certified quality management system. We provide a one-year warranty on your metal injection molding parts.

Free Tooling Design

With over 20 years of expertise in tooling design, BLUE offers free, high-precision mold design services to meet your customized needs. Let our experience work for you!

OEM/ODM Services

Using advanced equipment, we provides free mold design based on your drawing and offers assistance with your cotomized product processing.

China Metal Injection Molding Company - BLUE

We provide high-quality metal injection molding services backed by years of production experience and a strict quality control system.

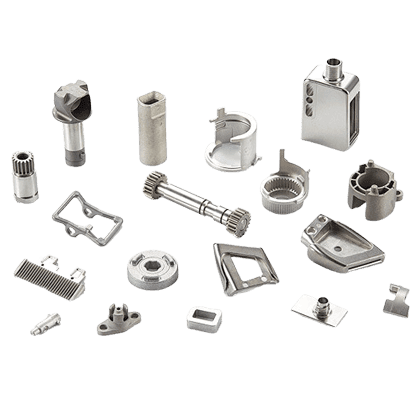

Metal Injection Modling Parts

Our metal injection molded parts provide precision features for gears, hinges and insert components.

Metal Injection Molding Products

These metal injection molded products combine complex geometry and high density for reliable structural strength.

MIM Metal Parts

MIM metal parts achieve fine surface finish and tight tolerances, reducing secondary processing.

Metal Injection Molded Parts

Metal injection molded parts start as fine metal powder that is blended with binder, injection-molded, degreased, and finally sintered to near-solid density.

Metal Injection Molded Products

Metal injection molded products can achieve 94–99% density and 1 μm Ra surface roughness.

MIM Product

MIM products combine near-net-shape manufacturing with high material efficiency, ideal for producing intricate and compact components.

What is Metal Injection Molding?

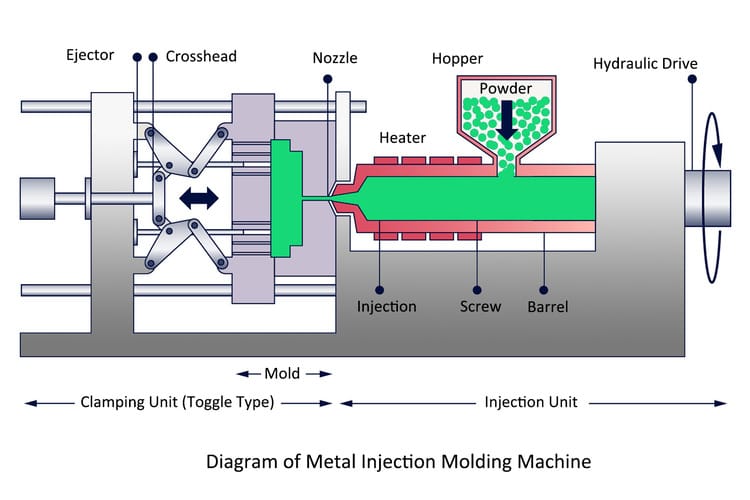

Metal Injection Molding (MIM) blends fine metal powder with a thermoplastic binder to create a moldable feedstock. The warm feedstock is injected into a steel mold, forming a “green” part that already holds intricate details such as thin walls, threads, or internal channels.

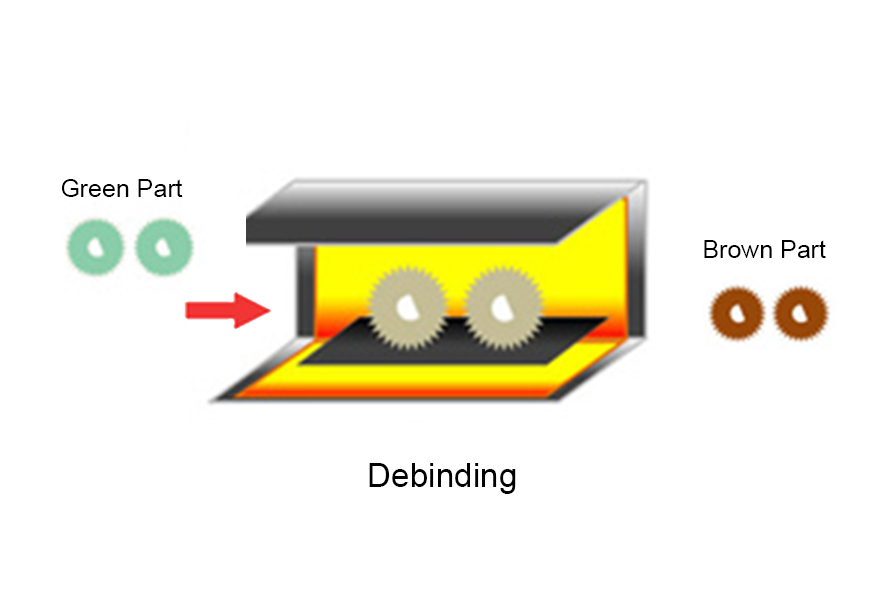

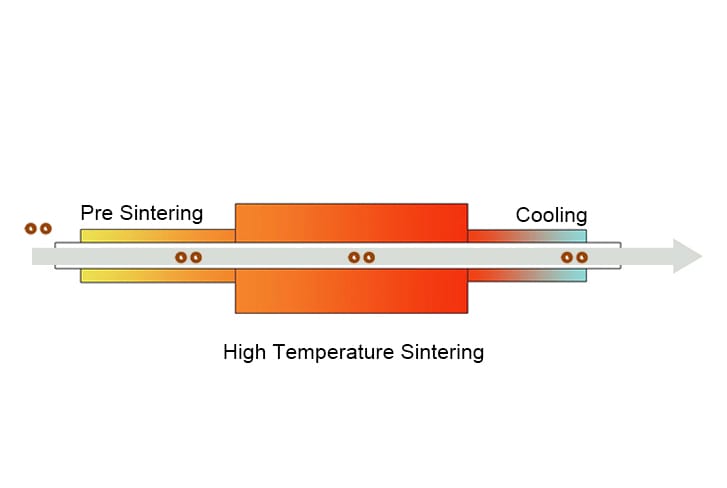

The binder is then removed by solvent, catalytic, or thermal debinding, leaving a porous “brown” part that is sintered at high temperature in vacuum or inert gas. Sintering fuses the particles to 96–99 % density, shrinking the part to its final, near-net dimensions and giving it mechanical properties comparable to wrought metal.

Metal Injection Molding Design Guide

Size & Weight: Avoid parts thicker than 12.5 mm (0.5 in) or heavier than 100 g.

Ejection & Geometry: Give long parts adequate draft, and avoid internal undercuts and closed cavities.

Feature Limits: Keep hole diameters and wall thicknesses above 0.1 mm, and round corners with radii larger than 0.05 mm.

Sintering Support: Include at least one flat surface to stabilize the part during sintering.

Metal Injection Molding Materials

Metal injection molding supports a variety of materials for different industries. Stainless steel is the most common, used in medical, aerospace, electronics, and consumer goods. Common grades include 17-4PH (strong, heat treatable), 316L (corrosion resistant, non-magnetic), and 440C (hard and wear resistant).

Low-alloy steels are used for bearings and hardware, tool steels for cutting tools, titanium for lightweight strength, and copper for conductivity.

Applications of MIM Parts

Metal injection molding is used to produce small, complex metal parts with high precision. Typical applications include:

Medical: Components for surgical tools, dental brackets, and oral implants.

Consumer goods: watch accessories, mobile phone camera holder, folding phone hinge,

Automotive: Fuel injectors, Turbochargers, valve lifters, clock mounts, entry locks, knobs, and levers.

Aerospace: Metal injection molding produces lightweight, high-strength components that improve fuel efficiency.

Advantages of MIM

- Design freedom: MIM fills thin walls, internal threads, undercuts and other intricate features in one shot, letting engineers combine multi-piece assemblies into a single component.

- High density: Metal injection molded parts can achieve densities of 94%-99% and have mechanical properties comparable to cast parts.

- Low waste: Because feedstock is molded to shape, scrap rates are commonly under 5%, saving material and supporting greener manufacturing.

- Volume cost savings: At tens-of-thousands production volumes, multi-cavity tooling and short cycle times make MIM cheaper per part than CNC machining

Custom MIM Parts Capabilities

The following are BLUE’s custom MIM components capabilities, including part size, weight, wall thickness, surface roughness, etc.

| Attribute | Minimum | Typical | Maximum |

|---|---|---|---|

| Mass (g) | 0.030 | 10 to15 | 300 |

| Dimension (mm) | 2 | 25 | 150 |

| Wall Thickness (mm) | 0.025 | 5 | 15 |

| Tolerance (%) | 0.2% | 0.5% | 1% |

| Density | 94% | 98% | 99% |

| Production Quantity | 1,000 | 100,000 | 100,000,000 |

Metal Injection Molding Process

Metal injection molding process consists of multiple and complex steps. Fortunately, BLUE has over 10 years of experience in designing and manufacturing MIM parts. Our products are widely used in the automotive, power tools, medical, and electronics industries, delivering exceptional quality and precision for your needs.

Designing

MIM parts design needs to consider numerous factors such as material selection, part geometry, wall thickness, sintering shrinkage, etc.

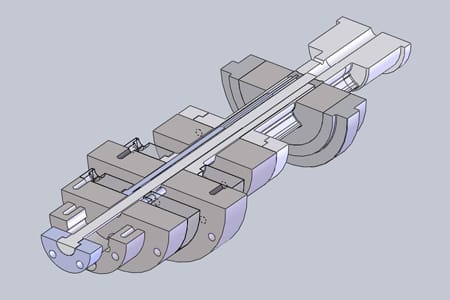

Tooling

The feedstocks enter the hopper, pass through the feed barrel, and are injected into the mold by the injection molding machine to form green parts.

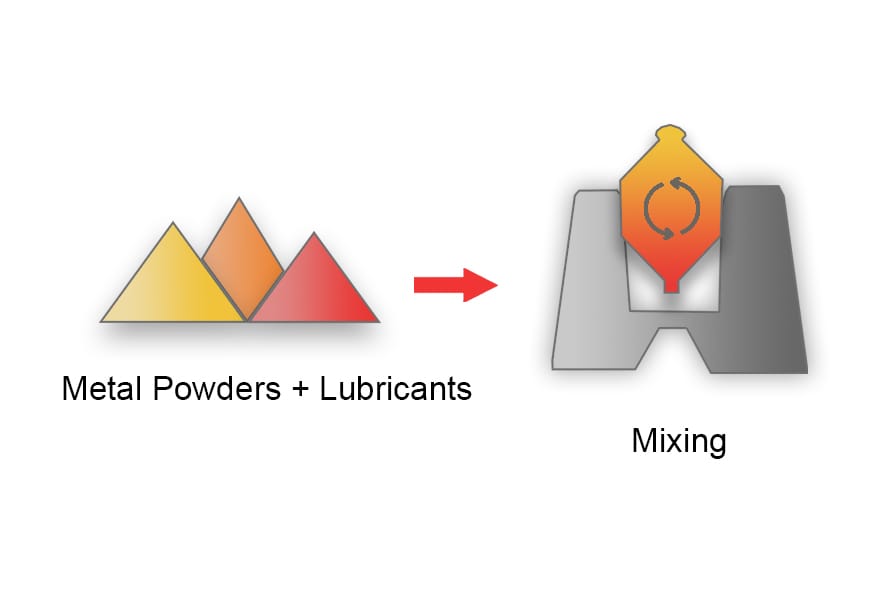

Mixing

Metal powder and binder are mixed in a ratio of 60:40 to form the raw material, called "feedstock". Binder makes metal powder have better fluidity and adhesion.

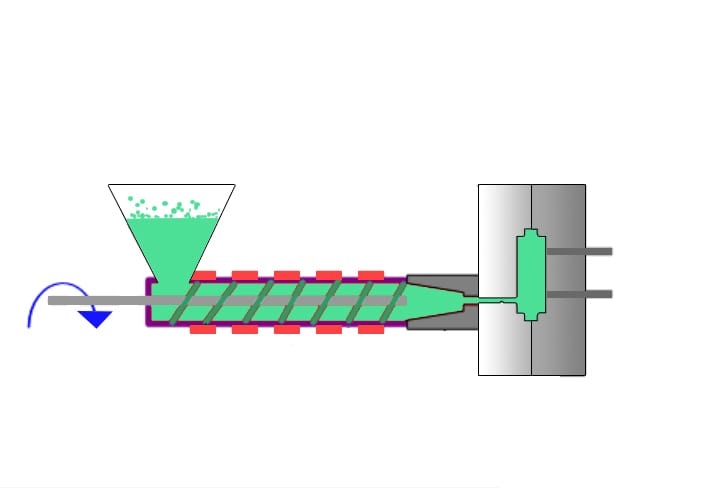

Injecting

The feedstocks enter the hopper, pass through the feed barrel, and are injected into the mold by the injection molding machine to form green parts.

Debinding

Debinding is to remove the binder in the green parts. Debinding processes include thermal debinding, solvent debinding, catalytic debinding, etc.

Sintering

Sintering heats the components to a temperature below its melting point in a controlled atmosphere to obtain the desired mechanical properties.

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

Metal injection molding covers multiple processes, such as mixing, injection, degreasing, sintering, secondary processing, etc., and it takes about 20-30 days

MIM parts utilize fine metal powder and high-cost molds, making the initial investment substantial. Additionally, the required equipment includes injection molding machines, degreasing units, sintering furnaces, and secondary processing machines. Consequently, MIM offers a price advantage primarily in mass production scenarios.

MIM parts utilize fine metal powder and high-cost molds, making the initial investment substantial.

We use secondary operations to improve the mechanical properties, dimensional accuracy and surface appearance of sintered MIM parts, including machining, heat treatment, embossing, machining, surface treatment and hot isostatic pressing.

- Avoid using components thicker than 12.5 mm or thinner than 0.5 mm.

- Avoid components weighing more than 100 grams.

- Avoid long pieces without a draft angle of at least 2° to allow for ejection.

- Avoid holes with a diameter less than 0.1 mm.

- Avoid uneven wall thicknesses.

- Avoid sharp corners; use radii greater than 0.05 mm.

- Avoid internal closed cavities.

- Avoid internal undercuts.