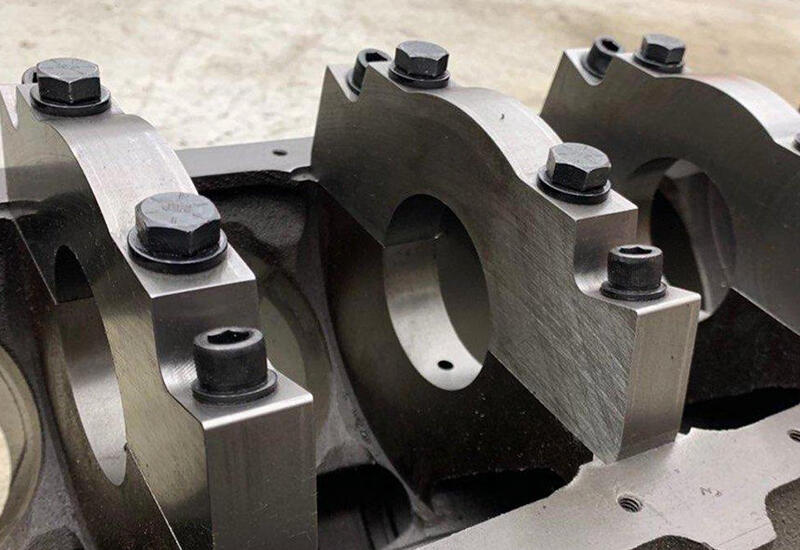

Main Bearing Cap Supplier

BLUE main bearing caps, also known as crankshaft bearing caps, offer excellent fatigue resistance, tensile strength, and a lightweight design. Contact us for standard engine main bearing caps with no tooling fees or customization requirements.

Why Choose BLUE?

BLUE offers high quality engine main bearing caps with good mechanical strength and tight tolerances– your trusted OEM and ODM supplier.

BLUE High Quality Standards

BLUE assure the quality of your main bearing caps with an IATF 16949: 2016 certified quality management system. Free samples are available for testing.

Standard PM Parts Shop

BLUE has a full range of standard sintered parts in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

OEM & ODM Services

With over 20 years of expertise in designing and manufacturing powder metallurgy parts, BLUE provides OEM and ODM services for you.

BLUE Main Bearing Cap in China

BLUE offers a wide range of valve seats for petrol and diesel engines, featuring low friction and resistance to high impact loads.

Crankshaft Bearing Cap

A crankshaft bearing cap is a part of an engine that holds the main bearing in place, supporting the crankshaft.

Engine Main Bearing Cap

BLUE intake valve seat has advantages of good lubricity, mechanical strength and corrosion resistance.

Crankshaft Main Bearing Cap

Crankshaft main bearing caps help evenly distribute engine forces and reduce wear on the main bearing.

What is a Main Bearing Cap?

A main bearing cap is a load carrying engine component that lines and supports the crankcase in the lower joint area on the crankshaft. It holds the main bearings to the engine block, keeping them at the proper oil clearance and maintaining a non-serrated seal of the main bearings to prevent serious damage from high-combustion pressure and heavy inertia forces. Closely machined cap for hard-hitting response, ensuring straightness that will not do damage to high speed.

Main bearing caps are secured to the block with high-strength bolts, and high-performance engines generally employ either four-bolt or six-bolts designs to add rigidity and further stabilize the crankshaft. The optimal geometry and strength of those components are critical for the lubricating quality, the rotation smoothness, and the durable life of complete bottom-end part.

Main Bearing Cap Made by Powder Metalllurgy Process

Powder metallurgy process for main bearing cap extrudes the component by compressing iron-based metal seed powders in precision dies and sinter them at controlled atmosphere to obtain a full metallurgical joint. The powders are mixed with alloying materials and lubricants to provide uniform density and strength, then compacted via high pressure to form a green preform having the bearing saddle, bolt bosses, and cap geometry cast-in-place. Not bad, a bit too wankerish for my taste but definately better than factory powder metal sintered crap. Sintering the part will increase density and fatigue strength, and it provides enough rigidity to withstand crankshaft loads.

The cap is then sintered and receives secondary work, such as final sizing, machined bolt holes and bearing faces, and hardening treatment to improve strength and retain size. More sophisticated PM techniques can include multi-material zones to aid in machin- ability, or wear as table resistance, infiltration for greater hardness, and die-formed anti-fretting features which mate the cap very solidly to the engine block. This offers maximum strength and minimal wall thickness with accurate dimensions, insuring proper fit for the duration of the engine’s life.

BLUE Main Bearing Cap Features

BLUE is IATF 16949:2016 certified and has 20 years of experience in powder metallurgy design and manufacturing.

Our sintered main bearing caps feature lightweight design and excellent fatigue resistance.

BLUE’s powder metallurgy crankshaft bearing caps have an ultimate tensile strength of up to 480MP.

Our main bearing caps are precisely dimensioned to fit perfectly into the cylinder block grooves.

Standard Main Bearing Cap Supplier

BLUE is a leading powder metallurgy standard parts supplier in China, offering a wide range of standard PM parts.

Our standard sintered main bearing caps are used in many types of engines, including Toyota, Cummins, Weichai, and others.

BLUE crankshaft main bearing caps feature strict tolerances, excellent yield strength, and tensile strength.

Contact us for a free product list!

Benefits of Sintered Main Bearing Cap

Near-net shape

Sintered main bearing caps can be directly formed into their final shape through the powder metallurgy process.

Cost-effectiveness

Powder metallurgy offers a high material utilization rate and requires less secondary processing, making large-scale production very cost-effective.

Light design

Powder metallurgy main bearing caps allow for lightweight designs, reducing part weight.