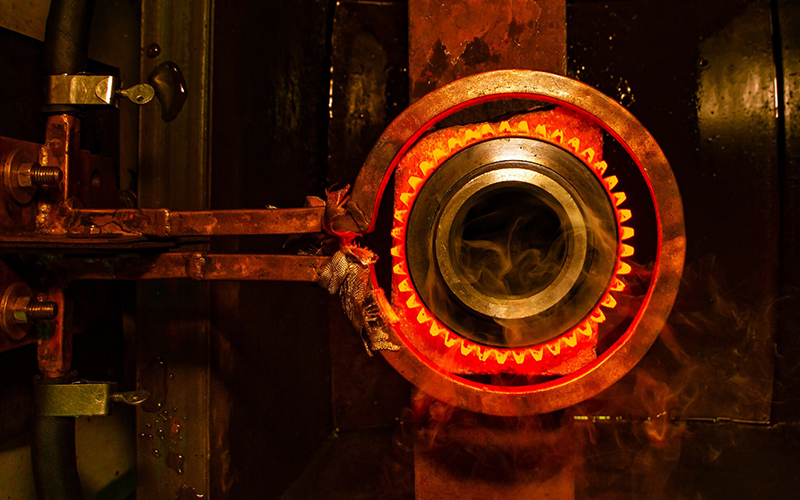

Heat Treatment of Powder Metallurgy Parts

Heat treatment is a controlled thermal process consisting of heating, holding, and cooling cycles to modify the microstructure and mechanical properties of metallic materials. In powder metallurgy (PM) components, heat treatment is applied to enhance hardness, tensile strength, and wear resistance by refining grain structure