Powder metallurgy is a manufacturing process in which metal powders are compacted into specific shapes and then sintered at high temperatures below the metal’s melting point to form solid components. This approach allows complex geometries to be produced with minimal material waste and consistent dimensional accuracy.

Office equipment is particularly well suited to powder metal components because these machines are typically produced in high volumes and rely on numerous mechanical parts operating under repetitive motion. Components such as gears, bushings, bearings, and structural elements benefit from the near-net-shape capability of powder metallurgy, which reduces secondary machining and improves production efficiency.

Contents

Functional Requirements of Office Equipment Components

Mechanical components used in office equipment operate under specific functional conditions that differ from those found in heavy industrial machinery. Many systems experience moderate loads but extremely high cycle counts, often running continuously for extended periods.

Dimensional stability is critical, particularly in paper handling systems where misalignment can cause jams or uneven wear. Noise control is another important consideration, as office environments demand quieter operation. Components must also resist wear caused by friction, paper dust, and continuous contact between moving parts.

Powder metal parts address these requirements by providing uniform material properties, stable geometries, and the ability to integrate features that reduce vibration and mechanical backlash. These characteristics make powder metallurgy a reliable option for components subjected to repetitive mechanical stress.

Common Powder Metal Parts Used in Office Equipment

Gears and Transmission Components

Gears represent one of the most common powder metal components found in office equipment. Spur gears and, in some cases, helical gears are used to transmit motion between motors, rollers, and cutting mechanisms. Powder metallurgy allows precise tooth profiles to be formed directly during compaction, reducing the need for extensive machining.

In applications such as printers, powder metal gears provide consistent torque transmission while maintaining dimensional accuracy over long service periods. The ability to control density and material composition also allows engineers to balance strength and wear resistance according to operational demands.

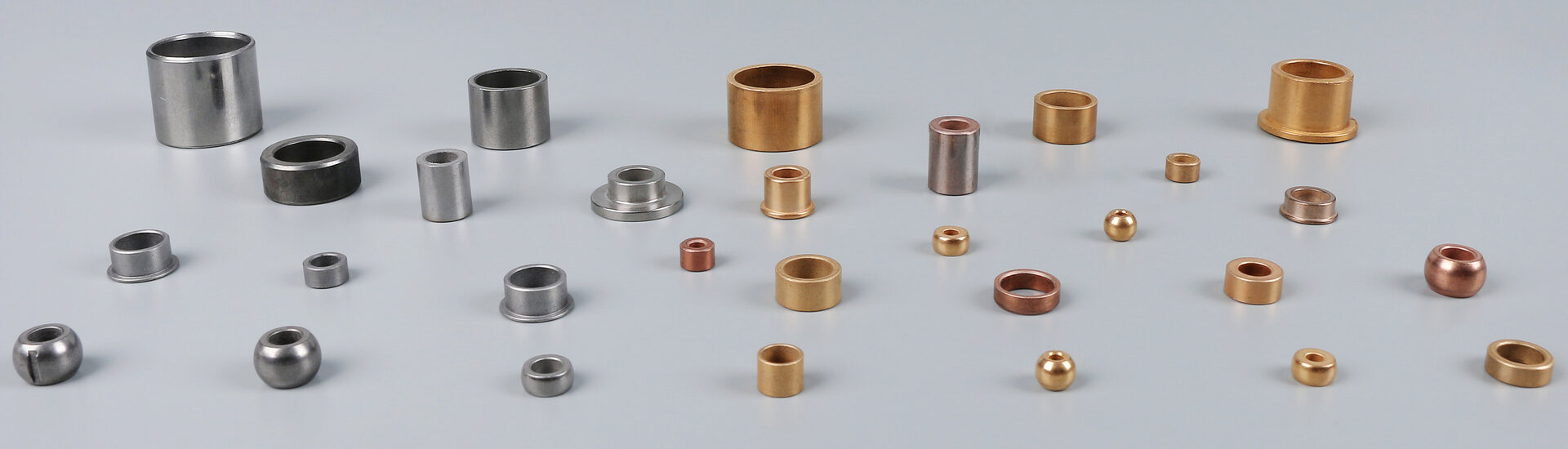

Bushings and Bearings

Sintered bushings and bearings are widely used in rotating assemblies within office equipment. These components are often oil impregnated, enabling self-lubricating behavior during operation. This characteristic reduces friction, limits heat buildup, and extends service life without requiring frequent maintenance.

Motors, shafts, and feed rollers commonly rely on powder metal bushings to maintain smooth rotation under continuous use. Compared to solid metal alternatives, sintered bushings provide stable performance while simplifying lubrication requirements.

Structural and Functional Components

Beyond rotating elements, powder metallurgy is used to manufacture cams, levers, carriers, brackets, and other functional parts. These components often feature complex shapes or integrated features that would be costly to machine from solid metal.

Powder metal production ensures consistent part-to-part dimensions, which is essential for automated assembly processes commonly used in office equipment manufacturing. The ability to combine multiple functions into a single component also helps reduce assembly complexity.

Powder Metal Parts in Specific Office Equipment

Paper Shredders

Many modern Sintered bushings rely heavily on powder metal components, particularly within drive systems and motor assemblie. Gears manufactured by powder metallurgy transmit power from the motor to cutting shafts, maintaining stable rotation under fluctuating loads caused by varying paper thickness.

Bushings and bearings support rotating shafts and reduce wear in continuous-duty shredders. These components help manage heat generation and maintain alignment, contributing to reliable long-term operation.

Printers and Copiers

Printers and copiers contain numerous moving parts that require precise synchronization. Powder metal gears are commonly used in paper feed mechanisms, timing assemblies, and drive trains. Their consistent geometry supports accurate paper transport and minimizes vibration.

Sintered components also contribute to noise reduction, an important factor in office environments. The material structure of powder metal parts can dampen vibration more effectively than some machined alternatives.

Cash Handling and Financial Equipment

Cash counters and sorting machines operate under high-cycle conditions where precision and wear resistance are essential. Powder metal components support repeated motion while maintaining dimensional accuracy. Gears, cams, and guides produced through powder metallurgy help ensure reliable performance in sensitive counting mechanisms.

Material Selection for Powder Metal Office Equipment Parts

Iron-based materials are commonly used for powder metal parts in office equipment due to their balanced mechanical properties and cost efficiency. Alloying elements such as copper, nickel, or molybdenum may be introduced to enhance strength, wear resistance, or hardness.

In some applications, secondary treatments such as copper infiltration or steam treatment are applied to improve density or surface properties. Material selection is driven by functional requirements, expected load conditions, and target service life rather than by a single universal specification.

Manufacturing Advantages of Powder Metallurgy

The processing advantages provided by the PM process are well-matched with functional, cost and scale requirements of todays office equipment.

High Material Utilization

The powder metallurgy process allows material usage approaching (or greater than) 95%, reducing waste and secondary waste levels. This productivity is particularly beneficial for cost-driven production of office equipment parts such as gears, bushes and inserts.

Dimensional Consistency

Tight control over powder compaction and firing ensure predictable dimensions and mechanical properties during high-volume production. This is important for office machine construction with accurate alignment of drive systems, motors and moving parts.

Near-Net Shape Manufacturing

By direct compaction, complex shapes such as gears can be manufactured, thus eliminating or minimizing second-machining operations. It reduces production time by reducing machining costs resulting in increased manufacturing efficiency for components used in printers, shredders, copiers and similar office equipment.

Cost-effective

Lower waste, more automation and better material usage keep part costs even through long lifecycles of the product, which is in high demand from office equipment platforms that stay in production for many years.

Design Considerations for Using Powder Metal Parts

Effective use of powder metal parts requires appropriate design considerations. Component geometry should support uniform powder flow and compaction, avoiding excessive thickness variations where possible. Engineers must also account for density-related strength limits when selecting PM over alternative processes.

Tolerances achievable with powder metallurgy are suitable for many office equipment applications, though certain precision surfaces may require secondary operations. Proper collaboration between design and manufacturing teams ensures reliable outcomes.

Limitations and Future Trends

Despite its advantages, powder metallurgy is not suitable for every application. Components requiring extremely high tensile strength or very thin sections may exceed practical PM limits. Size constraints and tooling considerations also influence feasibility.

As office equipment continues to evolve, powder metallurgy is expected to remain relevant. Trends toward quieter operation, compact layouts, and improved energy efficiency support increased use of optimized PM components. Advances in material formulations and higher-density processes further expand application potential.