Pressureless sintering is a sintering process in which powder material is converted into dense components without applying external pressure during sintering. The process depends solely on controlled heating to promote atomic diffusion and bonding between particles. It is used for producing components where uniform microstructure, dimensional stability, and cost efficiency are key requirements, such as in ceramics and metal powder components.

Contents

Pressureless Sintering Process

Powder Compaction

The process of pressureless sintering begins by compacting the powder material into a green body of required shape and geometry.“Typical powder compaction methods include uniaxial pressing, cold isostatic pressing, and injection molding. Here the proper compaction of powder material is ensured in order to achieve required contact between the particles for sintering.

Preheating

After the green body formation, the part is heated gradually in a controlled atmosphere to remove the binder, solvent, or any moisture. The preheating of the components is done to:

- Ensure uniform temperature distribution within the parts,

- Reducing thermal gradients

- Minimizing the risk of cracks or distortions during the subsequent sintering stage.

Sintering

At this stage, the pre-sintered part is now heated at an elevated temperature below the melting point of the material. This is the point where atomic diffusion and mass transport occur, causing particles to bond, pores to shrink, and the material to densify.

Sintering temperature and dwell time is critical for optimizing density, mechanical properties, and microstructure. For example, a study showed that in the sintering of silicon carbide (SiC), increasing the temperature from 1950°C to 2180°C resulted in a relative density exceeding 98% after a 1-hour dwell time at 2150°C.

Controlled Cooling

Finally, the sintered parts are subjected to controlled cooling because the slow and uniform cooling relieves internal stresses and prevents cracking or warping. Not only does this, by carefully managing the cooling rate, the manufacturer ensures dimensional stability and maintains the mechanical integrity of the sintered components.

Types of Pressureless Sintering

Vacuum Sintering

In vacuum pressureless sintering, the green body is subjected to sintering under vacuum to prevent the material from oxidation or contamination. Vacuum sintering is particularly suitable for materials that are prone to oxidation and require high sintering temperatures. including ceramics, stainless steel and tungsten.

Protective Atmosphere Sintering

Protective atmosphere sintering is performed in the presence of inert gases, such as argon and nitrogen. Using a protective atmosphere prevents the material from undergoing unnecessary reactions, such as oxidation, decarburization. It helps maintain surface cleanliness and controlled carbon levels, though oxide removal typically requires a reducing atmosphere.

Reducing Atmosphere Sintering

In reducing atmosphere sintering, gases like hydrogen or forming gas are used to reduce metal oxides. This promotes more effective atomic diffusion and pore elimination, enhancing densification and mechanical integrity. For example, metal powders such as iron and tungsten oxides undergo simultaneous reduction and sintering, resulting in components with higher density, finer microstructure, and improved mechanical strength.

Solid Phase sintering

In pressureless solid phase sintering, the compact die is sintered solely in the solid state; no liquid phase is present. Particle bonding and densification occur through atomic diffusion, which is strongly dependent on the sintering temperature and time. Solid-state pressureless sintering can produce relatively dense materials with uniform microstructures, though complete densification often requires long times or additives, and excessive temperatures may cause grain growth.

Liquid Phase sintering

Liquid phase pressureless sintering is a technique in which a small fraction of the material melts during the sintering process, while the remainder stays solid. This molten phase promotes particle rearrangement, solution reprecipitation, and enhanced diffusion. This allows densification of material at temperatures lower than those required for solid-state sintering.

Liquid phase sintering can be classified into two types:

Permanent Liquid Phase Sintering

In this method, the liquid phase remains present throughout the sintering process. Here the liquid facilitates particle packing and pore filling helping to achieve high density.

Transient Liquid Phase Sintering

In transient liquid phase sinteirng, liquid exists only temporarily; it forms at a lower temperature and reacts or solidifies during sintering, leaving a fully solid microstructure.

Advantages of Pressureless Sintering

Near-net-shape Production

One advantage of pressureless sintering is its ability to retain near-net shape geometry of pre-compacted parts. Since no external pressure is applied during heating, dimensional distortion and warping are minimized, preserving the precision of complex shapes.

However, minor distortion may still occur from uneven shrinkage or temperature variations during heating. When the initial compact has uniform density and the temperature profile is well controlled, shrinkage is relatively uniform.

Improved Mechanical Properties

Components produced by pressureless sintering can achieve good mechanical strength and durability when high densification is reached. This improvement results from the high densification and formation of a uniform, well-bonded microstructure during the sintering process.

Wide Material Compatibility

Pressureless sintering is compatible with a wide range of materials, allowing manufacturers to tailor compositions and additives to meet specific property requirements. It is effectively used for stainless steel, copper alloys, tungsten, and advanced ceramics such as alumina and zirconia.

Cost-effectiveness

Pressureless sintering enables near-net shape production of components that eliminate the need for secondary operations. Not only this it is useful for producing components on a large scale with minimal material wastage. All the factors combined make it highly economical and efficient for industrial production.

Applications of Pressureless Sintering

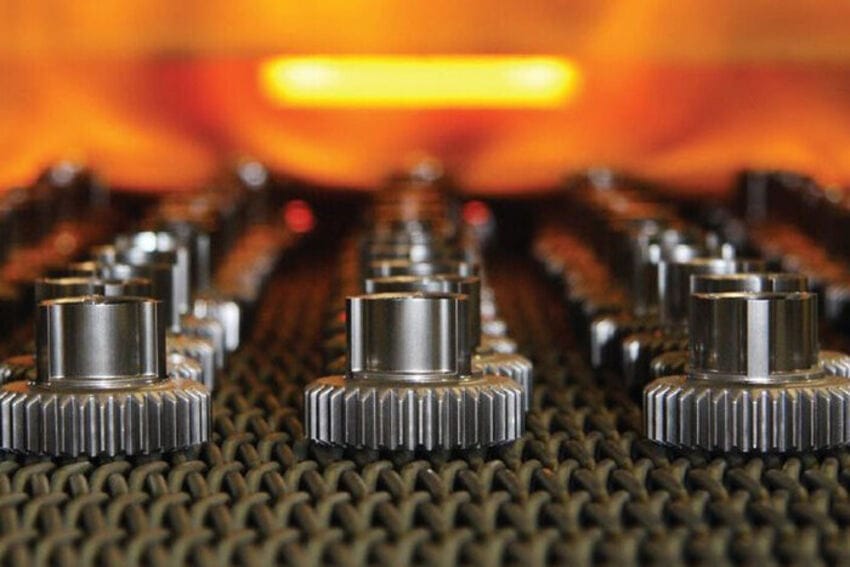

Metal powder

Pressureless sintering is widely used to produce powder metal components made from stainless steel, copper, and other alloys for structural applications. It is also applied in manufacturing self-lubricating bearings and filters where precise control of porosity is required.

Ceramics

Pressureless sintering is used for the production of high-performance ceramic components with high thermal stability and wear resistance. For example, this technique is used for producing sealing rings, nozzles, and biomedical device parts using alumina.

Metal-Ceramic Composites

This method is also employed for the production of metal-ceramic composites designed to operate under high-stress conditions. For example, a study showed that boron carbide combined with tantalum carbide (TaC) can be processed through pressureless sintering. This resulted in a metal-ceramic composite with around 98.7% relative density, as well as excellent hardness and electrical conductivity. Such composites are applied in armor systems, cutting tools, and high-temperature structural components,

Refractories

Pressureless sintering is suitable for refractory materials such as alumina, zirconia, silicon carbide, and boron carbide.