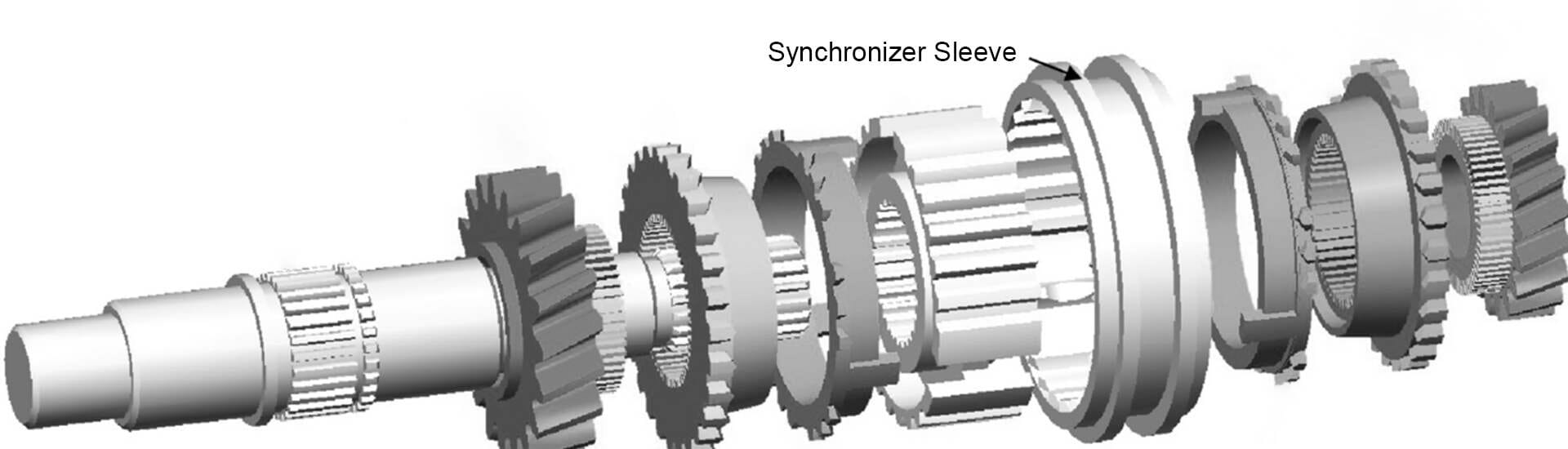

A synchronizer sleeve, also known as a sliding sleeve, is a precision-engineered axial coupling component within a manual transmission synchronizer assembly. Synchronization sleeve works with the synchronizer hub and baulk (or blocker) ring to match the rotational speeds of the shaft and the selected gear before engagement.

When this synchronization is achieved, the sleeve locks at the gear-to-shaft for effective torque transmission. Without this coordination, gear engagement would result in harsh noise or damage.

Contents

Powder Metallurgy Process for Synchronizer Sleeve

The following is a typical manufacturing route for producing synchronizer sleeves through powder metallurgy process.

Powder Preparation and Mixing

To manufacture the synchronization sleeve, metal powder, including iron (Fe) with 0.2-0.3 wt% carbon (C), 0.5-4.0 wt% nickel (Ni), and about 2.0 wt% molybdenum (Mo), is mixed together. The ratio of these powders is adjusted according to required mechanical strength, formability, and cost efficiency. For example,

- Nickel enhances toughness

- Molybdenum improves hardenability

- Carbon influences density and shock resistance.

Compaction and Forming

Now this powder mixture is compacted using a die of required sliding sleeve shape and geometry. During this stage, splines and chamfers are integrated directly into the mold design. The chamfer radius is maintained typically between 0.2 and 0.5 mm. This will prevent tool wear and eliminate the need for post-machining.

Sintering

The compacted green body is now subjected to a sintering process in a reducing atmosphere at 1120°C for about 2 hours. The sintering chamber is filled with a mix of nitrogen and hydrogen. During sintering the diffusion between metal particles enhances the bonding, and a density of about 7.3 g/cm3 is achieved.

Sizing and Finishing

For more precision and dimensional accuracy, the sleeve formed is subjected to sizing, where it undergoes tapering, chamfering, and milling to refine internal splines. Finally, the sleeve is carburized and heat treated to improve surface hardness and wear resistance.

Advantages of Sintered Synchronizer Sleeves

Compared with forged and machined sleeves, the powder metallurgy route shortens production by integrating splines and chamfers directly during compaction. This eliminates multiple machining steps and lowers cost. With a density above 7.3 g/cm³, sintered synchronizer sleeves reach about 1000 MPa yield strength and 720 HV hardness after heat treatment.

Types of Synchronizer Sleeve

Single-cone synchronizer sleeves

The single-cone synchronization sleeve relies on a single friction surface between the blocker ring and the constant mesh gear. In this synchronizer higher axial shift forces are required for proper synchronization because of the single friction interface. Although these sliding sleeves are effective for general gear ranges, they struggle with high-speed differentials in lower gears. They require precise friction management to avoid upshift noise or clutching issues.

Multi-cone synchronizer sleeves

The multi-cone synchronization sleeve incorporates multiple friction surfaces through intermediate rings. This design reduces the shift force by up to 40% in triple-cone systems and enhances synchronization performance, especially for lower gears with high-speed differentials. By optimizing cone positioning and friction distribution, multi-cone sleeves provide:

- Smoother engagement

- Lower shifting effort

- Improved handling of high torque compared to single-cone sleeves.

Signs of a Worn-Out Synchronizer Sleeve

Here are some signs that indicate that synchronization sleeve is not working properly:

- Worn or damaged synchronization sleeves can cause grinding or unusual noises while shifting or downshifting.

- A damaged sleeve can make it hard to move the shift lever smoothly between gears. So, it will be difficult to change gear if your synchronization sleeve is damaged.

- A faulty sliding sleeve may prevent shifting altogether, potentially requiring towing for inspection.

- Lastly, worn sleeves can cause the transmission to unexpectedly slip into neutral while driving.

Applications of Synchronizer Sleeve

Automotive Manual Transmissions

Synchronization sleeves are essential components in passenger vehicle synchronization systems, facilitating seamless gear shifts. This synchronization prevents gear clash and

Heavy Machinery

In heavy-duty machinery, such as construction equipment and trucks, synchronizer sleeves are crucial for managing substantial torque. They also handle the varying speeds of the engine and transmission. In heavy machinery synchronizer systems with multiple cones are utilized to ensure smooth gear engagement under challenging operating conditions.

Agricultural Equipment

Agricultural machinery, including tractors and harvesters, relies on synchronizer sleeves to facilitate gear shifting in demanding environments.