Powder metallurgy (PM) is widely applied in agricultural machinery, where components must endure heavy loads, abrasive conditions, and limited lubrication. The process combines near-net-shape forming, design flexibility, and cost advantages for mass production. Sinter-hardening and carburizing improve surface durability, while oil impregnation imparts self-lubricating properties.

Contents

Common PM Parts in Agricultural Machinery

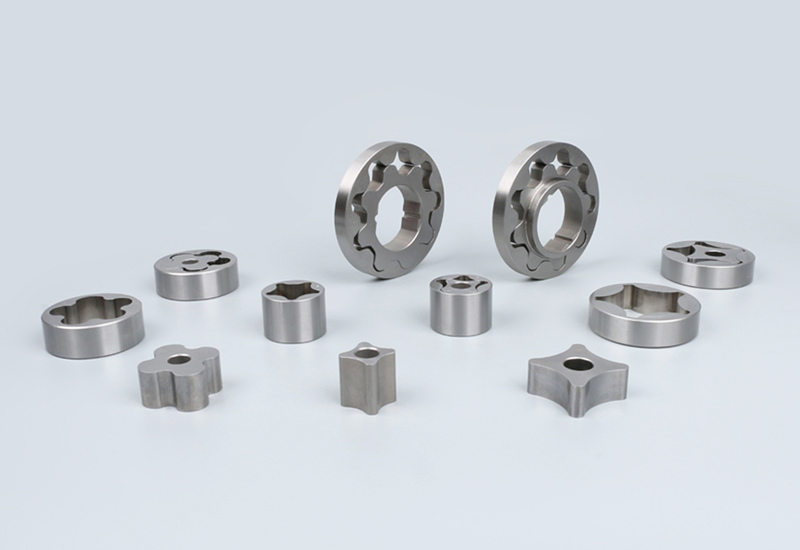

Gears and Sprockets

PM sprockets are present in numerous farming equipment, such as balers, tractors, and seeders. They are responsible for transferring power from the engine to other parts of the machinery, such as cutting blades, conveyors, and seed distribution systems.

In agricultural equipment, some small and medium gears and sprockets are made by powder metallurgy process. Sintered sprockets and gears achieve excellent wear resistance through alloy design and surface hardening, while their porosity enables oil impregnation for self-lubrication. The high precision in their design, including tooth profile, number of teeth and pitch, This is achieved by a precision powder metallurgy process.

Bearings and Bushings

Powder metallurgy enables the production of sintered bushings with precise dimensional tolerances, typically within the IT5 to IT7 range. These bushings feature inherent porosity that, when impregnated with oil, provides self-lubricating properties. This significantly reduces maintenance requirements and enhances durability in demanding agricultural environments.

These are present in wheels and axles of tractors and harvesting machines, helping them in a number of operations. These include movement of conveyor belts, cutting blades and other rotating components of harvesters.

Types of Sintered Bushings Used in Agriculture

Various types of bushings and bearings are utilised in agricultural machinery, including:

- Ball Bearings: They are used because of their ability to manage axial and radial loads.

- Sleeve Bushings: Sleeve bushings are simple cylindrical plain bearings that provide low-friction support in high-dust environments like tillers or pivots.

- Flanged Bushings: These bushings usually feature a flange for axial positioning. They are commonly used in linkages and hinges to prevent lateral movement.

Clutch Components

In agriculture, clutch components enable controlled power transfer for operations like gear shifting, stopping, or idling without stalling the engine. This is done by connecting and disconnecting the clutch. PM is a key technique that is used for the manufacturing of clutch parts because of its strength, cost efficiency and wear resistance.

Key clutch components produced via PM in agricultural equipment include clutch disks, hubs, retainers, and plates, especially in power take-off (PTO) systems. These components must withstand high torque loads and frequent engagement cycles while maintaining reliability in harsh field conditions.

Pump Components

Various pumps and their components produced through PM are used in agriculture, such as hydraulic pumps and oil pumps. Some key internal parts can also be produced through powder metallurgy, such as:

Rotors & Impellers

Powder metallurgy produces components with precision geometries and high tolerance, such as internal rotating elements of gear pumps, vane pumps, or gerotor pumps. PM enables near-net shaping, reducing machining and material waste.

Pump Bodies & Housings

PM parts can be sealed (e.g. via resin impregnation) so they resist leakage even under fluid pressure.

Valve Plates & Ports

In hydraulic systems, valve plates and ports can be produced by PM with high dimensional control and hydraulic compatibility.

Valve Guide

PM is used to manufacture engine valve guides because it allows for control over porosity, wear properties, and lubrication retention.

Connecting Rods

While less common than in clutches or pumps, connecting rods in small engines and power units can also use PM in certain designs. Powder forged connecting rods can be cost-effective in mass production with good fatigue performance when properly processed.

Powder Metallurgy Materials for Agricultural Applications

Iron and Steel Alloys

- These alloys are widely used for high-strength parts such as clutch hubs, gears, sprockets, and connecting rods.

- Iron or steel can be sinter-hardened, carburised, or heat-treated to improve hardness and wear resistance.

Stainless Steels (300 & 400 Series)

- Stainless steel alloys are applied in pump rotors, impellers, and valve components requiring corrosion resistance in hydraulic or oil-based systems.

- They offer durability in harsh environments with exposure to water, fertilisers, or chemicals.

Copper and Bronze Alloys

- Copper is suitable for valve guides, bushings, and bearings due to natural anti-seizing properties and good thermal conductivity.

- Oil-impregnated bronze bushings are common in rotating agricultural machinery.

Nickel and Alloyed Steels

- Nickel provides higher fatigue strength and toughness for demanding components such as connecting rods and high-load gears.

- These are used in applications requiring resistance to impact and shock loading.

Advantages of PM for Agricultural Machinery

Cost-effective in high volume

PM offers a cost-effective route for producing high volumes of various agricultural equipment, as it generates minimal material waste, achieves energy efficiency, and minimises machinery requirements.

Material Efficiency

PM uses various materials such as titanium which are hard to machine to produce near-net-shape components for the agriculture industry. Not only this, but it also ensures the optimal performance of the component by blending alloying elements. It produces low scrap compared to casting and forging, being a more sustainable approach.

Design Flexibility and Complex Geometries

PM allows the creation of intricate shapes and complex geometries that are difficult to obtain with conventional machining. Many features, such as internal channels, splines, and complex profiles, can be directly formed during the compacting process.

Self-Lubrication

PM components such as sintered bushings can be designed with a porosity and subjected to oil impregnation process. It provides self-lubricating properties to the components, minimising friction and extending the lifespan of moving parts in harsh conditions.

Wear Resistance

Components manufactured through powder metallurgy exhibit wear resistance, as they are capable of withstanding tough conditions, including high loads, vibrations, and extreme temperatures.

BLUE is a professional powder metallurgy manufacturer with 20 years of experience. We are ISO 9001:2015 certified and provide a full range of standard powder metal parts with no tooling cost required. You can browse our SHOP or download our product list for free.

We also supply customized PM components tailored to your application. Working with BLUE means cost-effective solutions, consistent quality, and fast delivery you can rely on.