Spray forming, also called spray casting, is a metallurgical process that forms near-net-shape components with low segregation and a uniform microstructure. The process combines the phenomena of atomization, deposition and consolidation. Spray forming can easily utilize the alloys to manufacture components which are difficult to cast, such as nickel, based alloys, high-speed steel etc. This advanced manufacturing process is used to manufacture rings, disks, and seal segments for aero-engines. Not only this, but it is also used to manufacture tube, tool, and cylindrical extrusion-clad bars.

Contents

Spray Forming History

In the 1970s, Singer and his team used the spray forming successfully for manufacturing meal components at the University College of Swansea. He demonstrated that gas atomization could form metal strips directly from molten metal. Osprey was the first company to use this process at the commercial level. That’s why it was also called the Osprey process. Later on, Liquid Dynamic Compaction (LDC) was also utilized to manufacture metal components, which emphasized rapid solidification to improve material properties. Over time, metal spray forming paved the way for its use in near-net shape manufacturing.

Spray Forming Process

Melt Preparation

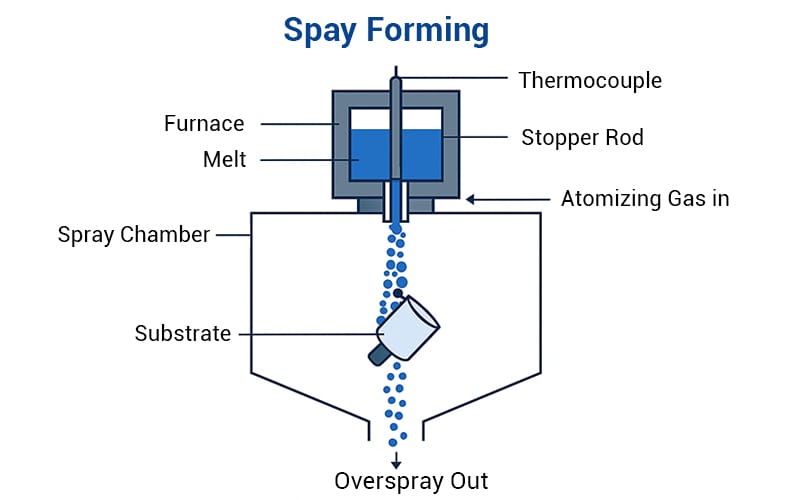

In the first step of the spray-forming process, a clean, premixed metal melt is prepared in a crucible. Here:

- In order to reduce the thermal gradient, it is maintained at very low superheat.

- To prevent oxidation, the melt chamber is purged with an inert gas such as nitrogen or argon.

- A slight overpressure is applied to maintain a protective atmosphere.

Melt Delivery

Now, this melt is discharged from the bottom of the crucible through a tundish into the atomization zone. In this step, a steady, controlled flow of melt is ensured for proper atomization.

Atomization

In the automation chamber, fast-moving inert gas mixes with the melt, forming small droplets. The size of these droplets ranges from 20–200 μm. The gas jet is not only responsible for producing small droplets but also provides convective cooling and initiates rapid solidification as droplets travel through the spray.

Droplet Cooling and Acceleration

Leaving the atomization chamber, the droplets accelerate to speeds of 50–100 m/s while cooling in flight. Around 60–80% of latent heat is removed from droplets within a few milliseconds of atomization. The remaining heat dissipates over a period of up to 300 seconds. In this way, the droplet solidifies upon reaching the substrate in various stages.

Deposition on Substrate

Finally, the droplet falls on the moving or stationary substrate, flattens and solidifies to form a dense consolidated deposit. The density of the material here ranges from 96 to 99.5%.

Microstructure Development

The metal spray forming process promotes supercooling, resulting in fine, equal size and particle shape in all directions. The composition of the material remains uniform due to the absence of macrosegregation.

Applications of Spray Forming Process

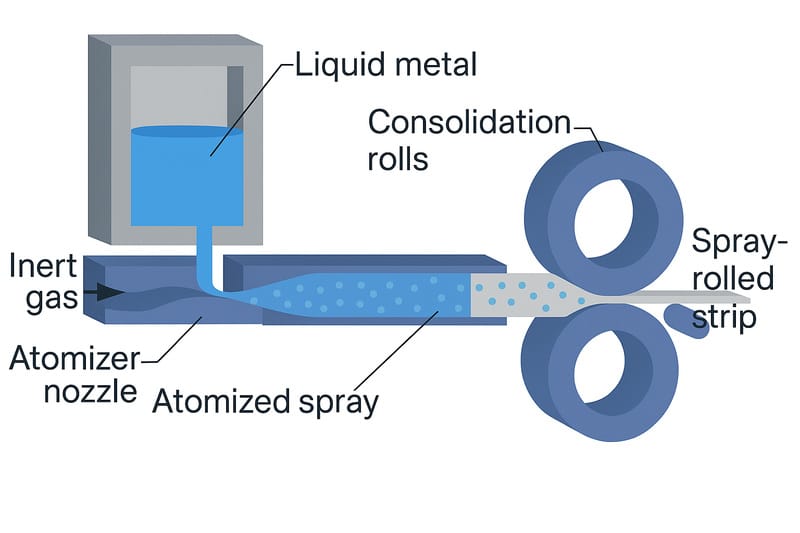

Strip and Sheet Production

Metal strips and sheets with refined grain structures are manufactured by spray forming. These sheets and strips are highly corrosion-resistant and possess remarkable mechanical properties.

Rings and Tubes

One of the most remarkable applications of spray forming is the production of large-diameter rings and seamless tubes. These rings and tubes are manufactured for industries where high strength-to-weight ratios and uniform microstructure are critical. They are mainly produced for aerospace components and power generation equipment.

Structural Materials

Spray forming is also widely used in the production of structural metals across various industries. This includes materials like aluminum, steel, and copper alloys.

Aluminum Alloys

The production of multiple Al based alloys is done through Spray forming, such as:

- Al-Si alloys for automotive applications. These alloys offer improved wear resistance and castability to the components.

- Al-Li alloys for aerospace and marine applications.

Advantages of Spray Forming

Near Net Shape

In spray forming semi solid metal particles are directly deposited on substrate producing near net shape material. This not only results in minimizing the material waste but also lowers the overall production cost.

Fewer Defects

The process is done in an inert atmosphere, which means there’s less chance for the metal to react with oxygen or other gases. This helps prevent defects in the final product.

Lower Cost and Energy Use

One exceptional advantage of metal spray forming is that it doesn’t require expensive molds or tools and uses less energy. This makes it cost-effective and fast.

Even and Fine Microstructure

Spray-formed materials tend to have small grain sizes and fine secondary phases. As a result, they have an even internal structure, which offers better mechanical properties.

High Density

In conventional powder metallurgy process, due to the limited pressing process and low sintering efficiency, the density of parts is usually about 95%. Whereas in spray forming high part density typically up to 98% is achieved by minimizing porosity.

Limitations of Spray forming data sources

Porosity in the Final Product

Although spray forming is well known to produce fine microstructures of material, the final product still has small internal holes, such as cast porosity. That’s why it may require processing like rolling or extrusion.

Metal Losses

A good amount of metal can be wasted during the process. This includes:

- Overspray: Metal droplets that miss the target.

- Bounce-off: Droplets that hit the surface but don’t stick.

- Machining: Extra material that must be removed later.

High Cost of Inert Gases

We know that spray forming requires inert gas for the atomization of molten metals, but these are quite expensive, making the process less economical.

Difficult Process Control

It’s challenging to monitor and control the process in real-time, making it difficult to ensure consistent microstructure and shape without extra adjustments or corrections.