Synchronizer Hub Manufacturer

BLUE offers sintered synchronizer hubs with precise internal and external spline tooth profile, good durability, and high strength. Our synchronizer hubs are available in various models for both manual (MT) and dual-clutch transmissions (DCT).

Why Choose BLUE?

BLUE provides high-quality synchronizer hubs with good mechanical strength and wear resistance, along with free mold design services—your trusted OEM and ODM supplier.

BLUE High Quality Standards

BLUE assure the quality of your sintered synchronizer hub with an IATF 16949: 2016 certified quality management system. Free samples are available for testing.

Standard PM Parts Shop

BLUE has a full range of standard PM parts in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

OEM & ODM Services

With over 20 years of expertise in designing and manufacturing powder metallurgy parts, BLUE provides OEM and ODM services for you.

BLUE Synchronizer Hub in China

BLUE synchronizer gear hub has high precision and can work perfectly with the output shaft and synchronizer sliding sleeve to ensure smooth speed change of the vehicle.

Powder Metallurgy Synchronizer Hub

Powder metallurgy synchronizer hub has high internal and external spline profile accuracy and can be precisely matched with the output shaft.

Sintered Synchronizer Hub

Sintered synchronizer hub uses D39, FC-0205, SMF4040 and other raw materials, and can be formed into the final shape in single pressing.

Powder Metal Synchronizer Hub

The hardness of the powder metal synchronizer hub tooth surface can reach 40HRC after heat treatment.

What is a Synchronizer Hub?

A synchronizer hub is a core component of a manual transmission, splined to the mainshaft so it rotates at the same speed as the shaft.. It is the mounting base for the snychronizer sleeve and together with the blocker ring it synchronizes shaft and gear speed when engaging, resulting in easy and noiseless shifting.

On a shift, the sleeve moves outward over the hub’s outer grooves and forces the blocker ring into engagement with a conical surface of a gear. The friction that is developed balances the hub and gear speeds. When in sync, the sleeve slides under (but is no longer pushed by) the blocker ring, and locks the gear to the shaft without grinding.

The Synchronizer Hub plays the key role of exact positioning, stable torque transfer and also resilient engagement in gearshifts.Its accuracy and wear resistance are critical for shift quality, which is why hubs are typically made from high-strength machined steel or P/M materials

Synchronizer Hub Made by Powder Metallurgy

A P/M synchronizer hub is obtained by compacting metal powders in a precision die so that the internal splines, external teeth and overall hub geometry are formed while in the near-net-shape condition. The compact is subsequently sintered at elevated temperature to give the desired strength, dimensional stability and wear resistance. This method is applicable for syncro hubs because it provides accurate spline profile and close tolerance for a smooth gear engagement.

Following sintering, secondary finishing operations are implemented to finish critical surfaces. These could include sizing to control dimensions, CNC machining for bores or chamfers, surface hardening by carburizing or induction hardening to improve fatigue and wear performance. Grinding of functional areas can also be performed when high precision is required.

P/M synchronizer hubs are widely used in manual transmissions due to their strength-to-cost efficiency, excellent repeatability, and ability to integrate complex features without extensive machining.

BLUE Synchronizer Hub Features

BLUE has been manufacturing powder metallurgy automotive parts for over 10 years, serving over 500 customers across 30+ countries worldwide.

After hardening, the hardness of our synchronizer hubs exceeds 40 HRC, with a tensile strength of 550 MPa.

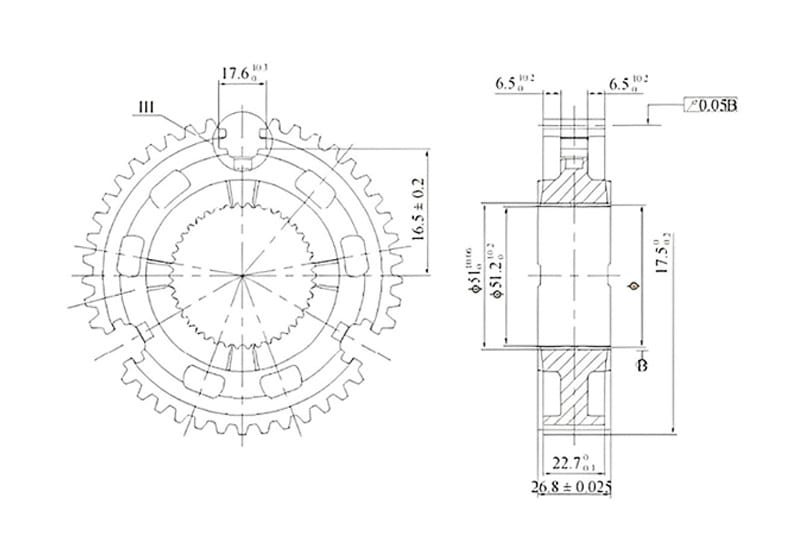

BLUE’s synchronizer hubs feature a tooth profile tolerance of 0.022 and a tooth direction tolerance of ±0.019.

Our synchronizer hubs have a clean appearance, free of burrs, flashes, and other defects.

High Frequency Quenching of Synchronizer Hub

High-frequency quenching is a heat treatment process used to harden the surface of metal parts.

After induction hardening, the synchronizer gear hub forms a hardened surface layer, improving wear resistance and fatigue strength.

High frequency quenching preserves core toughness and ductility, preventing brittle failure.

The overall hardness of the inner spline of the BLUE synchronizer gear hub after high frequency quenching quenching exceeds 400 HV₀.₅.

Adavantages of PM Synchronizer Hub

Near-Net Shape

Powder metal synchronizer hubs can be pressed into their final shape in a single compaction.

High Precision

Sintered synchronizer hubs feature high internal and external spline precision, achieving 8 grade accuracy.

Cost-effective in Large Quantity Production

Powder metallurgy enables cost-effective mass production of synchronizer hubs, thanks to reduced machining and high material utilization.

What is a Synchronizer?

Transmissions have been an integral part of vehicles for decades, designed to adjust speed and torque as needed

Synchronizer hub is an important parts in vehicle transmissions, used in both manual (MT) and dual-clutch transmissions (DCT).

Typically, synchronizer hubs feature external teeth, a rim, a boss, and internal splines, and three notches on the outer surface.

They are commonly produced through the sintering process, connected to the output shaft via splines, and positioned between two gears.

Custom Synchronizer Hub Specifications

The table shows our manufacturing capabilities for customized valve guides, including material, density, hardness, tolerance, and surface treatment.

| Attribute | Value |

|---|---|

| Material | FC-0205, FN-0205, FD-0205, FL-5305, SMF4040, SMF9060, D39 |

| Density | 6.8-7.0g/cm3 |

| Hardened Hardness | Min. 40 HRC |

| Surface Treatment | High Frequency Quenching, Hardening |

| Tolerance | ±0.01 mm |

| Accuracy of Tooth | DIN/ISO 6 – 8 |

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

The burrs on the synchronizer hub surface are primarily caused by an excessive gap between molds. The reasons for the increased gap include:

- Mold Wear: The die becomes worn after prolonged use, leading to a larger gap.

- Installation Errors: Incorrect installation of the mold can result in misalignment and an excessive gap.