Timing Chain Sprocket - BLUE

BLUE provides 500 standard timing chain sprockets including camshaft sprocket and crankshaft sprocket without mold fee. Our timing sprockets are applied to Toyota, Honda, Volkswagen, BMW, Audi, Chevrolet, Peugeot, etc.

Why Choose BLUE?

We have established ourselves as a reliable supplier of timing chain sprocket, offering free mold design service,, fast shipping, and competitive prices from China.

BLUE High Quality Standards

BLUE assurethe quality of your timing sprockets with an ISO 9001:2015 certified quality management system. Free samples are available for testing.

Standard Timing Sprocket Shop

BLUE has a full range of standard timng chain sprockets in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

Free Mold Design Service

With over 20 years of expertise in mold design, BLUE offers free, high-precision mold design services to meet your customized needs. Let our experience work for you!

BLUE Timing Sprocket in China

BLUE offers a wide range of standard sintered timing chain sprocket with high sintered density and great mechanical strength.

Powder Metallurgy Sprocket

BLUE powder metallurgy sprocket features tight hole tolerance, good compressive strength and durability.

Timing Sprocket

BLUE timing sprocket uses MPIF 35 FC-0205 as raw material, and has a reliable structure after sintering.

Powder Metal Sprocket

BLUE powder metal sprocket is made of 35 FC-0205, which has good hardness and corrosion resistance after steam treatment.

Custom Chain Sprocket

BLUE can offer custom timing chain sprockets for our clients according to specific requirements and provide free mold design services.

Sintered Sprocket

This sintered timing sprocket is used in the Land Rover Discovery II and Defender 2.5 Diesel TD5 models.

Crankshaft Sprocket Gear

BLUE crankshaft sprocket gear has a tight tolerance within ±0.015mm, used in BMW engines.

Sintered Metal Sprocket

This sintered metal timing chain sprocket is compatible with the Audi/Skoda/Seat vehicles equipped with 1.4 TSI and 1.6 FSI engines.

Engine Timing Crankshaft Sprocket

BLUE engine timing crankshaft sprocket has good mechanical strength and durability, specially used in toyota tacoma.

Sintering Metal Sprocket

Our sintering metal sprocket has high tooth profiles and inner diameter accuracy, and is precisely matched with the camshaft and crankshaft.

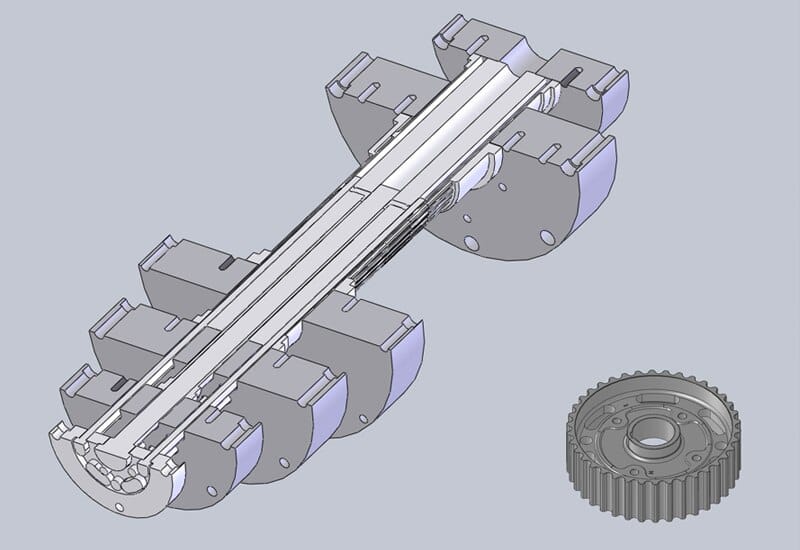

What are Timing Chain Sprocket?

Timing chain sprockets are precision gears mounted on the crankshaft and camshaft(s). They work with the timing chain to keep these shafts rotating in perfect sync so the engine valves open and close at the correct moments during the four stroke cycle.

The system uses a larger crankshaft sprocket and smaller camshaft sprockets. Their teeth engage the chain to transfer motion, similar to how a bicycle chain runs on multiple gears, and this maintains accurate engine timing.

Because sprockets wear over time, they are often replaced together with the timing chain to avoid timing errors, misfires, and reduced engine performance.

Timing Sprocket Manufacturing Process

Timing chain sprockets are commonly produced using P/M or precision machining. In P/M, metal powders are compacted in a die under high pressure to form the gear shape, then sintered at elevated temperatures to achieve strength and dimensional accuracy. This process is ideal for high-volume automotive sprockets because it provides uniform density, consistent tooth geometry, and excellent wear resistance.

After sintering, secondary operations are applied to meet tight tolerances. These may include sizing, CNC machining for critical bores or keyways, surface hardening such as carburizing or induction hardening, and final deburring. When required, grinding is used on functional surfaces to achieve high precision.

For forged or fully machined sprockets, alloy steel is forged into a blank, machined to final dimensions, and heat-treated to obtain tooth hardness and durability. Both methods aim to produce sprockets with stable tooth profiles, high fatigue strength, and long service life in the timing system.

BLUE Timing Chain Sprocket Advantages

BLUE’s powder metallurgy auto parts are produced under the IATF 16949: 2016 quality management system.

We provide you with timing chain sprockets with precision teeth and holes, which fit perfectly with your chain and camshaft or crankshaft.

BLUE timing chain sprocket teeth are surface-hardened to a high hardness of 40HRC, offering excellent strength and wear resistance

Our timing chain sprockets have a density of up to 7.0 g/cm3 after sintering and have good mechanical properties.

Standard Timing Sprocket Supplier

BLUE is one of the largest powder metallurgy standard parts companies in China, we provide a wide range of timing sprockets.

Our standard timing chain sprockets include camshaft sprockets and crankshaft sprockets.

BLUE standard timing chain sproket has good mechanical strength and strict dimensional tolerances.

Download our standard timing chain sprockets product list for free by clicking below.

Sintered Timing Chain Sprocket Benefits

Cost-Effective Mass Production

Compared to machined timing sprockets, powder metallurgy timing chain sprockets generate less material waste and require fewer processing steps.

Tight Tolerances

Sintered timing chian sprockets can achieve strict tolerances of ±0.01mm after the sizing process.

High Quality Consistency

Powder Metal timing chain sprockets offer excellent batch-to-batch quality consistency.

What is a Timing Chain Sprocket?

Timing sprockets are basic parts of the timing system in an internal combustion engine.

Connected to the camshaft or crankshaft, they drive the timing chain, ensuring the camshaft and crankshaft remain synchronized.

This synchronization allows the engine’s intake and exhaust valves to open and close at the correct times, matching the piston’s movement.

Custom Timing Chain Sprocket Specifications

The following table shows BLUE’s production capabilities for timing chain sprockets, including material, density, hardness, tolerance, diameter range, length, surface treatment, etc.

| Attribute | Value |

|---|---|

| Material | MPIF 35, FC-0205. FC-0208, FN-0205, FD-0208 |

| Density | 6.6-7.0g/cm3 |

| Hardness | 65-90 HRB |

| Surface Treatment | Blackening |

| Tolerance | ±0.01 mm |

Related Powder Metallurgy Auto Parts

As the largest supplier of powder metallurgy standard parts in China, BLUE offers a wide range of standard auto parts with no mold fee required.

Water Pump Pulley

Our water pump pulleys feature tight tolerances, high apparent density, and superior mechanical strength.

Timing Belt Pulley

Our timing pulleys are dimensionalally accurate and pair well with timing belts to smoothly transmit synchronous rotational motion.

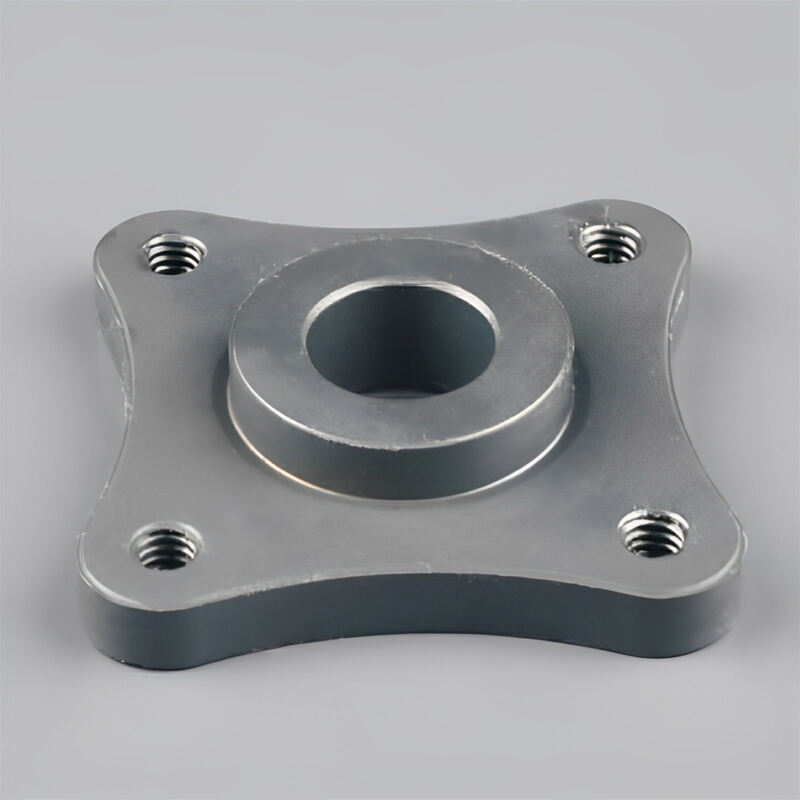

Water Pump Flange

Our pump flanges have the advantages of multiple models, tight tolerances and high mechanical strength.

Oil Pump Rotor

Our oil pump rotors have good surface finish, tight dimensional accuracy and excellent position tolerances to deliver optimal engine performance.