Top Quality Sintered Filter Manufacturer

BLUE’s sintered filters are available in a variety of different filtration ratings, materials, sizes and shapes and have been applied in various industries such as automotive, water treatment, petrochemical, food and beverage. We have standard sintered filters in stock for quick delivery.

All Kinds of Sintered Filter

BLUE offers sintered filter elements made from bronze, stainless steel, titanium, nickel, plastic and ceramic, available in various shapes including disc, tube, plate, candle, sheet, ring, rod, and cone. We also provide customized filter sizes, shapes, and filtration ratings, along with free samples to meet your specific needs.

Sintered Metal Filter

Sintered metal filter elements are available in a variety of materials, sizes, and shapes, with a wide range of filtration rating to choose from.

Sintered Stainless Steel Filter

BLUE's sintered stainless steel filter element has excellent corrosion and heat resistance, as well as long service life

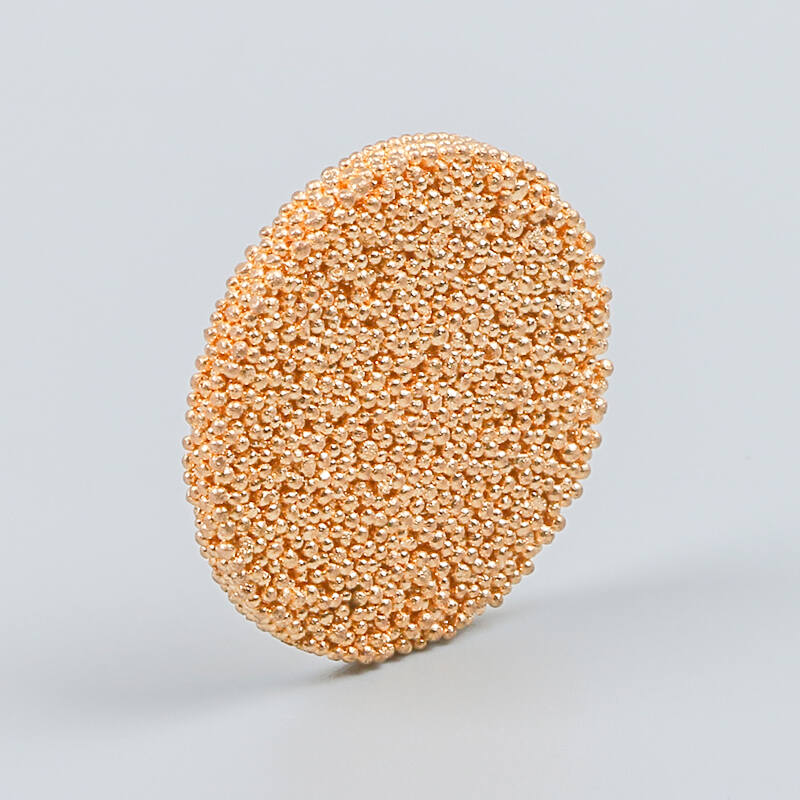

Sintered Bronze Filter

A sintered bronze filter element is a cost-effective option that offers good high-temperature resistance and filtration efficiency.

Sintered Ceramic Filter

Sintered ceramic filter offers high temperature and pressure resistance, excellent acid and alkali corrosion resistance and long lifespan.

Sintered Nickel Filter

BLUE's sintered nickel filter offers exceptional resistance to corrosion and can withstand high temperatures up to 1200°C.

Sintered Titanium Filter

Sintered titanium filter is a high-performance, lightweight filter with excellent oxidation, corrosion, and high-temperature resistance.

Sintered Metal Tube

Our sintered metal tubes offer filtration grades ranging from 0.5 to 100 μm and diameters from ⌀3 to ⌀150 mm.

Sintered Filter Disc

BLUE's sintered filter disc has excellent corrosion resistance, diameter ranges from 5 to 1000mm.

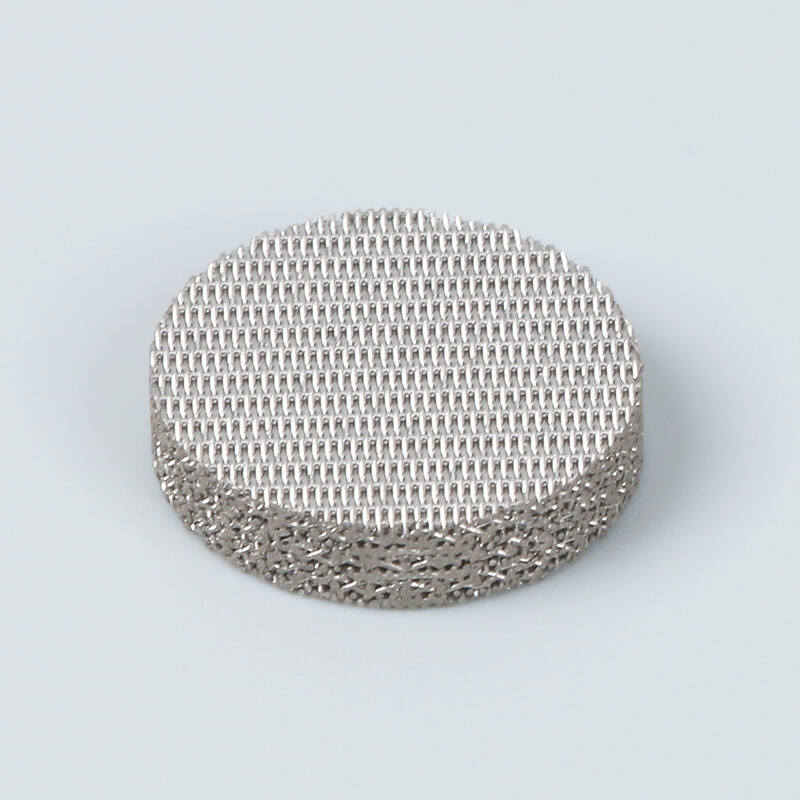

Sintered Mesh Filter

BLUE sintered mesh filters has very uniform filtration pores and extremely high filtration effect

Sintered Sparger

BLUE sintered spargers have uniform porosity and fine pore sizes, making them suitable for gas diffusion applications such as oxygen and carbon dioxide.

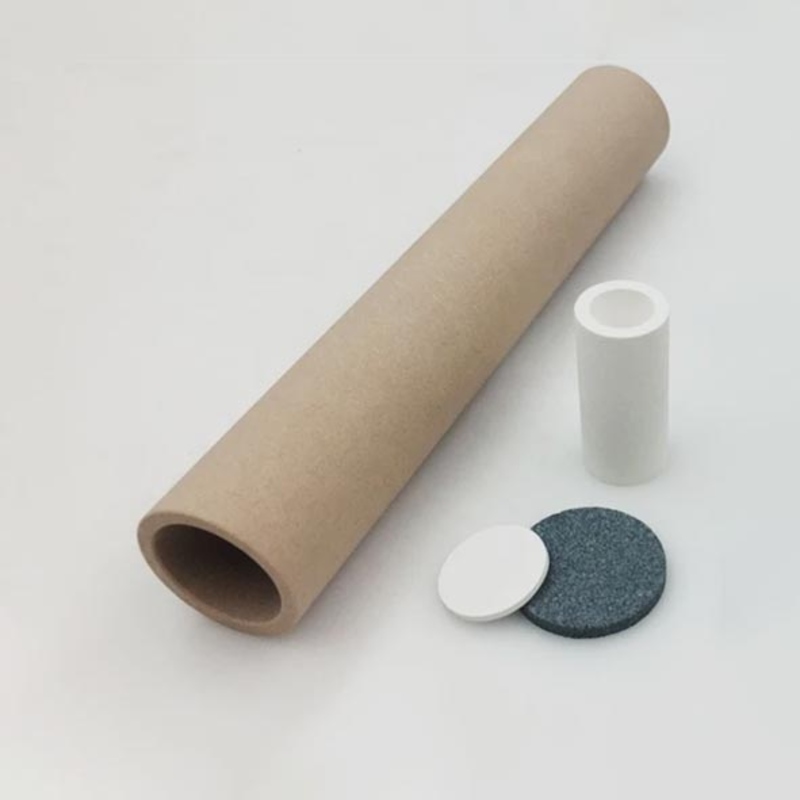

Sintered Filter Cartridge

Our sintered filter cartridges are crafted from stainless steel, titanium, or nickel, offering high temperature resistance up to 930°C and compressive strength up to 4 MPa.

Sintered Breather Vent

BLUE sintered vents provide high air permeability and good corrosion resistance, with standard thread sizes ranging from 1/8" to 2"

Sintered Plastic Filter

BLUE's sintered plastic filters offer you with a lightweight, economical filtration solution with a variety of shapes to choose from.

Sintered PTFE

Sintered PTFE filter has better heat resistance and chemical resistance than other plastics and has a smooth surface finish.

Sintered Plate

BLUE sintered plates are available in plastic, stainless steel, titanium, and nickel, with a maximum size of 1000×330mm and thickness ranging from 0.5 to 10mm.

Why Choose BLUE?

BLUE is your trusted sintered filter supplier, offering high-quality sintered filters, free samples, fast delivery, and competitive pricing from China.

BLUE Quality Standards

BLUE assures your product quality with ISO 9001:2015 certified quality management system. We provide a one-year warranty on your powder metal filter.

Standard Sintered Filter Shop

With over 10 years of expertise in sintered filters, BLUE offers a wide range of standard sintered filters in stock. Visit our shop to find what you require.

Download Sintered Filter List

Discover BLUE’s full range of powder metallurgy standard sintered powder filter. Download our free product list to find the exact match for your requirements.

BLUE's Sintered Filters Advantages

BLUE’s sintered porous metal filter elements can be customized with various pore sizes and filtration ratings to meet your specific needs.

We also offer customized shapes and sizes to perfectly fit your applications.

Our filters offer high filtration efficiency and are designed to be cleanable and reusable, ensuring a long lifespan.

BLUE sintered stainless steel filters excel in corrosion resistance, while our sintered nickel filters provide outstanding high-temperature performance and excellent pressure resistance.

Customized Sintered Filters Specifications

- Material: bronze, stainless steeel, plastic, ceramic, titanium, Inconel.

- Customizable Diameter: Standard and customized sizes are available, with a maximum radial size of 1000 mm.

- Customizable Thickness: Available from 1 to 100 mm.

- Working Temperature: Stainless steel filters: -200°C to 800°C; bronze filters: -200°C to 450°C; nickel filters: high-temperature resistance above 800°C; plastic filters: maximum working temperature of 260°C.

- Filter rating: Ranges from 0.2 to 300 μm.

- Shapes: Tube, plate, candle, sheet, disc, ring, rod, cone.

- Maximum Working Pressure: 55 bar.

Standard Sintered Filters Element

As a leading sintered filter supplier, BLUE offers a wide selection of standard sintered filters to meet all your filtration needs.

With no tooling fees, these filters can be produced and delivered quickly, ensuring you get what you need without delay.

Engineered to address common filtration requirements across various industries, our sintered powder filters provide reliable and efficient solutions.

Download our sintered filters from below botton to quickly find the perfect filtration solution for your specific application.

Applications of Sintered Metal Filter

- Automobile Industry

Sintered metal filters can filter automobile exhaust and reduce noise. - Filtering Oil and Natural Gas

Sintered filters can remove impurities from oil and natural gas. - Pneumatic Muffler

High-pressure gas entering the air can generate noise. Sintered filters can disperse these gases, increasing the contact area with the air and reducing noise. - Diffuser

Sintered filters can be used as oxygen diffusers, commonly found in aquariums. - Food & Beverage Industry

Sintered filters not only help filter oxygen and bacteria in food and beverages but also improve shelf life.

Download Product List

Sintered Muffler

BLUE's sintered silencer has uniform pores, significant noise reduction effect, long service life, and can be customized in various sizes.

BLUE's Other Manufacturing Capabilities

BLUE covers the full range of powder metallurgy processes, providing one-stop customization for powder metallurgy parts, MIM parts, sintered filters, and sintered ceramic components with strict quality control.

PM Parts

BLUE offers high-precision, strong powder metallurgy parts, customized to meet strict quality standards for various applications.

PM Tooling

BLUE has over 20 years of experience in powder metallurgy tooling design and production, with a service life of up to 500,000 cycles.

MIM Parts

BLUE's MIM parts feature flexible designs and top strength, produced with consistent quality for complex requirements.

Sintered Ceramics

BLUE's sintered ceramics offer excellent resistance to high temperatures and corrosion, along with good strength, hardness, and surface finish.

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

Sintered filter is a high-performance filter made of metal powder compacted and sintered. Sintered filter has excellent high temperature resistance, acid corrosion resistance, easy cleaning, high filtration efficiency, etc.

Surface Filtration

The interior of the sintered filter features a porous structure that blocks larger impurities on its surface, allowing liquid and smaller impurities to pass through.

Deep Filtration

The pores within the porous filter are tortuous and interconnected, causing smaller particle impurities to be adsorbed onto the internal pore walls during the flow process.

Here are some common cleaning methods:

Ultrasonic Cleaning

Place the sintered filter in a nitrogen-protected heating furnace and heat it to 380 degrees Celsius for two hours. Then, immerse the product in an ultrasonic cleaner for about 30 minutes.

Chemical Flushing

Use a chemical cleaner to dissolve contaminants in the sintered filter.

Pyrolysis Burning Off

For filters used in high-temperature applications, such as sintered titanium and nickel filters, expose them to high temperatures to burn off contaminants.