There is a wide range of metal powder production methods. Have you heard atomization?

Atomization in powder metallurgy is a process that turns molten metal into powder using an atomization medium, such as gas or water.

Contents

Gas Atomization in Powder Metallurgy

Gas atomized powders are mainly used in metal injection molding, hot isostatic pressing and 3D printing.

Gas Atomization Process

It is ideal for producing fine metallic powders, such as:

- Titanium powder,

- Stainless steel powder

- Tool steel powder

- Nickel alloy powder

- Iron alloy powder

Gas atomization is a common way for producing MIM metal powders, but the yield of finished products needs further improvement.

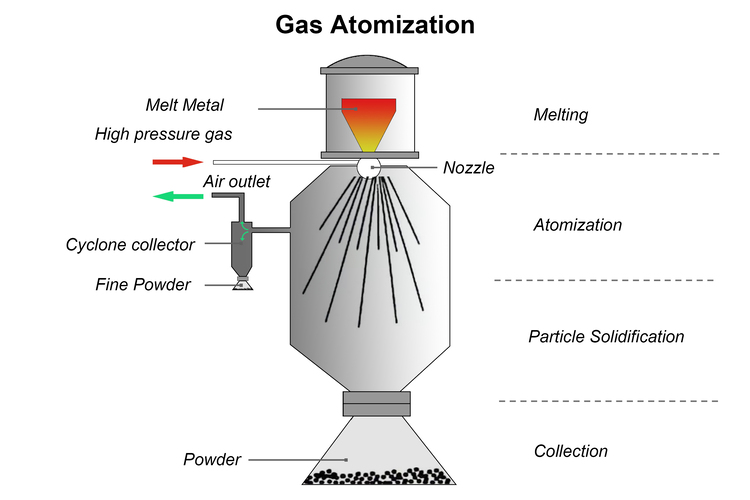

Gas atomization process includes 4 steps:

- Melting

First, manufacturers melt the metal block in a crucible.

- Atomization

After the metal is melted, the work opens the cylindrical plug at the bottom of crucible. The molten metal then flows through the nozzle and is atomized into droplets by high-pressure gas.

- Particle solidification

The metal droplets solidify into powder during flight.

- Collection

The solidified metal powder is deposited in the atomization chamber.

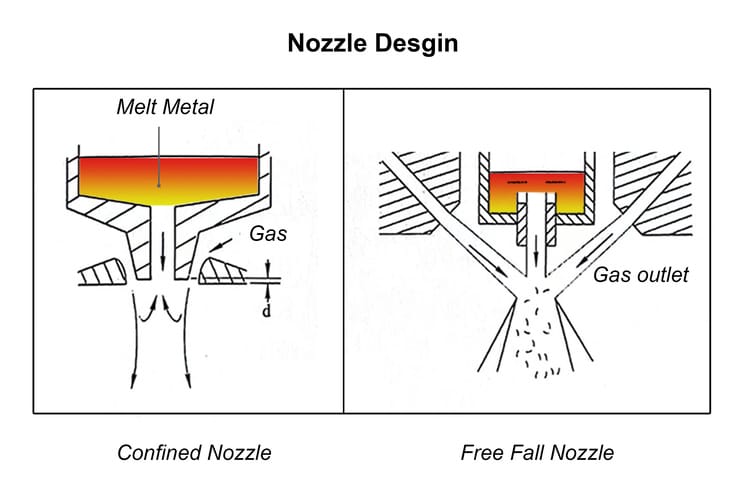

Nozzle Design

- Confined Nozzle

Confined nozzle brings the gas very close to the molten metal outlet, so that it is atomized immediately after leaving the crucible.

Moreover, the atomization is concentrated in a small and restricted area, and more gas energy is used in the spray. Therefore, this method has small energy loss and is easy to control the powder particle size. Confined nozzle increases the number of fine powder particles (<10 μm).

- Free Fall Nozzle

With an open nozzle, the molten metal is atomized below the crucible outlet. So this method has a low energy conversion efficiency.

Process parameters

- Surface tension of metal liquid

During the flight of metal droplets, surface tension facilitates their formation into spherical shapes. Surface tension is related to the temperature and the amount of alloying elements.

- Viscosity and temperature of metal liquid

High atomization temperatures result in lower viscosity of molten metal and longer solidification times. On the contrary, low atomization temperatures lead to higher viscosity of the molten metal, causing the liquid to more easily form irregular powders.

Therefore, increasing the atomization temperature helps the powder become finer, more spherical, and have a better surface gloss. For stainless steel, the temperature of the molten steel is typically about 1600°C.

- Gas flow rate, pressure, and speed

The greater the gas pressure and flow rate, the finer the metal powder produced. Generally, the atomization pressure of the gas is between 0.7 and 6 MPa.

- Type of atomizing medium

Gas atomization often uses the following atomizing medium:

- Air is more economical and suitable for metal liquids that are not severely oxidized, such as copper powder

- Nitrogen is ideal for metal liquids that are easily oxidized

- Argon can prevent nitridation

- Helium helps to increase the cooling rate.

The purity of the atomizing medium is very important. If the oxygen and water vapor content is high, the liquid metal will be easily oxidized. This will cause a thicker oxide film on the surface of formed powder. It will also increase the viscosity of the liquid metal, making it difficult for the powder to form a spherical shape and result poor surface gloss. Therefore, powder metallurgy materials manufacturers will add a small amount of silicon to absorb oxygen during the atomization process.

- Pressure and flow rate of metal liquid

The lower the liquid metal flow rate, the finer the atomized powder. The particle size of atomized powders have a direct impact on compaction behavior and sintering performance in powder metal parts manufacturing.

Pros and Cons of gas atomized powders

Pros

- High powder purity

- Low oxygen content

- High bulk density

Cons

- The cooling rate of metal droplets is slow.

- When using an induction furnace to molten metal, the metal powder produced may contain crucible materials, causing pollution.

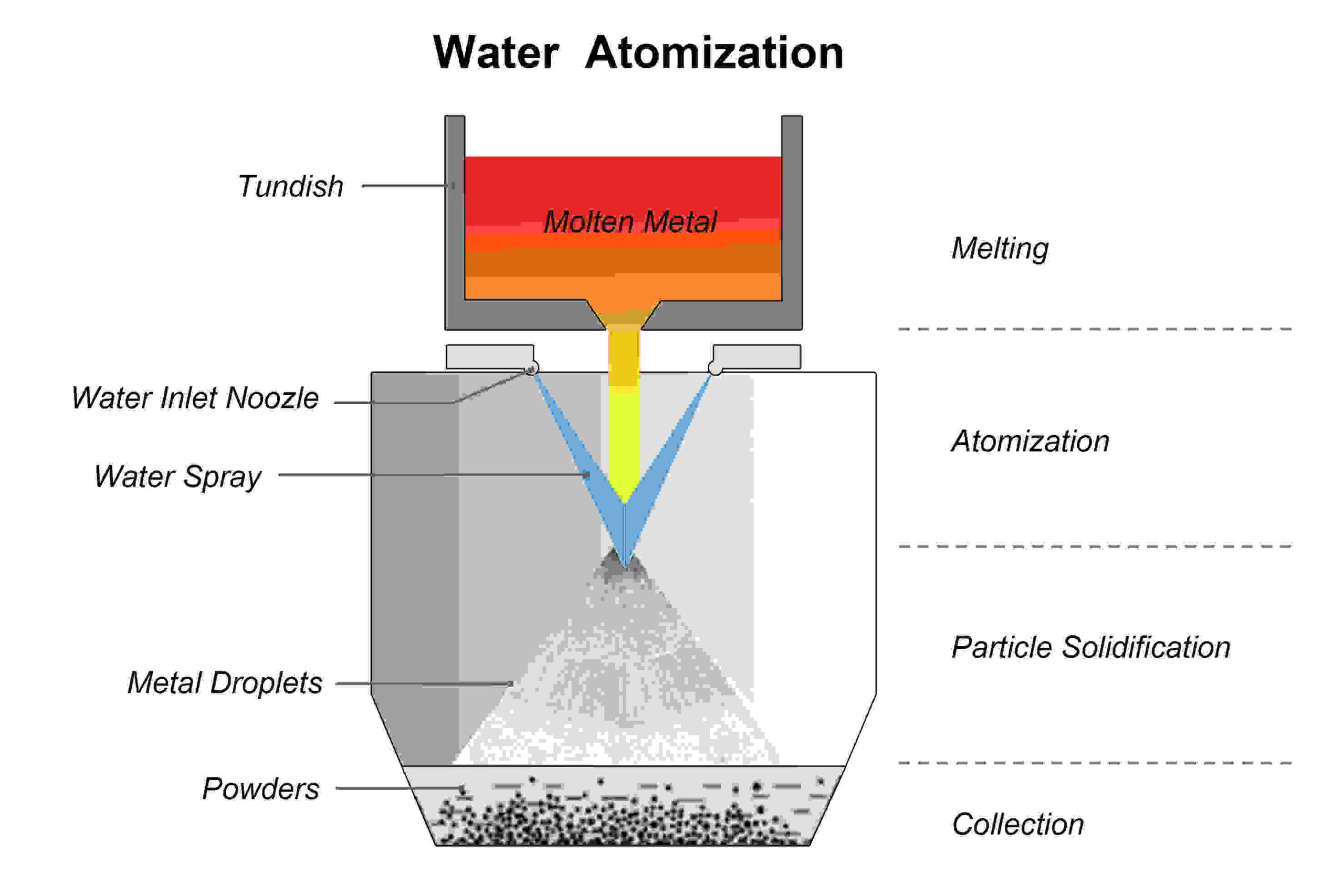

Water Atomization in Powder Metallurgy

Water atomized powders are used in powder metal parts due to their low cost and narrow particle size distribution.

Definition

Water atomization works like gas atomization. Molten metal is poured onto a rotating disk, then broken into droplets by high-pressure water jets. The droplets cool in a water bath, forming metal powder.

During water atomization process, higher water pressure produces finer powder. For ordinary iron powder, the water pressure ranges from 3.5 to 50 MPa. For fine powder used in metal injection molding, the pressure is generally between 50 and 150 MPa.

Advantages and Disadvantages of Water Atomization

Water atomization has low production cost and good green strength, but the metal particles produced have high oxygen content.

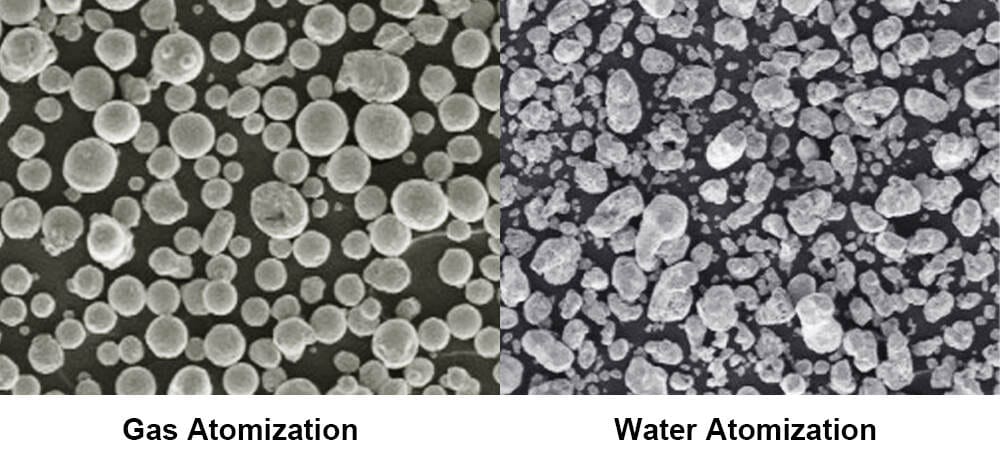

Compared with gas atomization, water atomization produces irregular particles. This is because water has greater kinetic energy and has a greater impact on the molten metal. As a result, the metal droplets solidify rapidly during flight, and there is not enough time to generate surface tension to form spherical particles.

However, the powders can be mechanically interlocked well, and the green strength after pressing is high

Factors Affecting the Particle Size

According to a study by the Royal Institute of Technology, the particle size of water atomized metal powders is related to the following factors:

- Water Pressure

- Melt Superheat

- Surface Tension

- Water Jet Configuration

- Material Composition

- Oxidation

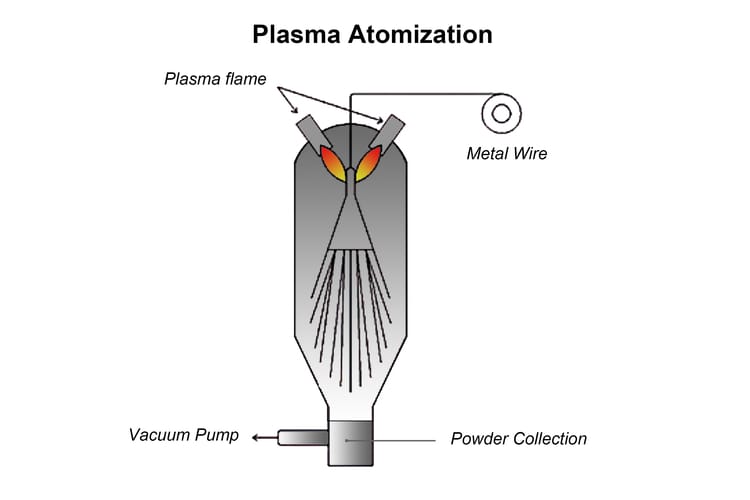

Plasma Atomization

In the plasma atomization process, the raw material enters as a metal wire. The metal wire is then melted by a plasma torch and broken down into particles by the plasma gas.

Metal powders produced by plasma atomization are about 40 μm in size with a narrow particle size distribution. These powders are high in purity, spherical, and have excellent flowability, making them ideal for additive manufacturing or 3D printing.

Pros

- Highly spherical powder

- High powder flowability

- Low oxygen content, no contaminants

- Customized size distribution

In addition, the plasma atomization process can also spheroidize irregularly shaped metal powders. The principle is to feed metal powder into the plasma flame, where the powder is melted again and spheroidized into powder by the surface tension. This process is known as the plasma spheroidization.

Ultrasonic Atomization

This process uses ultrasonic vibrations to break up liquid metal in thin film form into fine droplets. These droplets then solidify into spherical powder particles.

The process is capable of producing powders with particle sizes between 20 – 100 nanometers

Ultrasonic atomized powder has high sphericity and narrow particle size distribution, but its amount is low.

Centrifugal Atomization

First, the molten metal is introduced into the rotating disk. The high-speed rotation throws the liquid metal outward and atomizes it into powder.

In centrifugal atomization equipment, inert gas is usually introduced, the powder is less oxidized and has high purity.

Due to the stable rotation of the centrifugal atomization process, the powder particle size range is narrow and the appearance is regular and spherical.

Comparison of Gas and Water Atomization in Powder Metallurgy

| Process | Gas Atomization | Water Atomization |

|---|---|---|

| Metal | High speed steel, stainless steel | Iron, high speed steel, stainless steel |

| Particle Size | No more than 150 μm | No more than 150 μm |

| Particle Shape | Spherical shape | Irregular shape |

| Price | Slightly high | Medium |

| Applications | PM, MIM, HIP, AD | PM, MIM (except iron) |

FAQ

What is the Difference between Atomization and Atomisation in Powder Metallurgy?

In powder metallurgy, ‘atomization’ and ‘atomisation’ mean the same thing. The difference is purely regional: ‘atomization’ is used in American English, while ‘atomisation’ is used in British English.