Impregnation is a wonderful secondary process to fill the pores of powder metal parts. There is another process to do it—Infiltration.

Infiltration in powder metallurgy introduces molten metal through capillary action, filling the pores and solidifying to form a denser, more cohesive part.

Since copper infiltration is the most common infiltration processes, we will focus this blog on it.

Contents

Copper Infiltration in Powder Metallurgy

The following is the process flow of copper infiltration of powder metallurgy parts.

Calculate Parts Porosity

Firstly, you calculate the parts porosity, which is the volume percentage of voids in the material. Some measurement techniques, like density measurements or graphs, you might apply to measure porosity.

Calculate the Weight of Copper

Then you multiply total volume of parts by the porosity percentage to get required copper volume. Furthermore, you will know the weight of copper based on its density.

Make Copper Plates

You could use molds from green compact to make these copper plates. Or you press a round piece of copper and place it over the intricate part. After the copper plate is dissolved, it can still penetrate into all parts.

Copper Infiltration Method

Copper Infiltration in powder metallurgy typically employs the following two methods:

- One method is to place copper plates on top of compacted powder components. Then you sent them together to the sintering furnace. It is less expensive and requires no additional operations.

- The other is to place copper plates on top of sintered parts and then re-enter the sintering furnace. This method is more expensive, but the copper-infiltrated components have better mechanical properties.

Because, during first sintering process, a skeleton has already formed between metal powders and alloying has occurred. It is beneficial for the infiltration process. Besides, sintered metal parts have a certain strength. So you don’t have to worry about damaging them during transportation.

During copper infiltration process, we conduct tests by infiltrating different weights of copper into the components. This helps us determine the proper amount of copper and reduce costs.

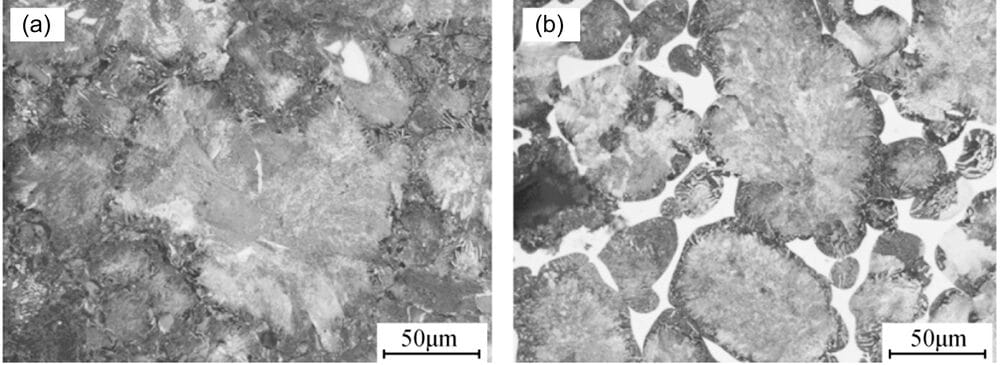

Experimental tests indicate that a 20% copper infiltration treatment is applied to iron-based parts with a density of 6.6-7.0 g/cm³. Its surface hardness can reach HRB 96-99, and its compressive strength can achieve 1120-1280 MPa without undergoing a hardening process.

The Metallographic of samples before and after copper infiltration

(a) Matrix sample; (b) 20% copper-infiltration sample

Additional Material during Infiltration Process

In addition to copper, some iron, manganese or zinc will also be added during Infiltration in Powder Metallurgy.

- Iron

The purpose of adding iron is to prevent the iron in the parts from melting and causing dents when the copper is melted. So you add iron first to pre-saturate it.

- Manganese, zinc

In order to absorb oxygen from the wetting environment and improve the wettability of copper to iron, you can add manganese or zinc. They facilitate the smooth entry of copper into the pores of iron-based components. Additionally, this will help the residue come off.

Advantages of Copper Infiltration in PM

Increase Density

Copper infiltration enhances the density of powder metallurgy parts. For example, Iron-based parts often have problems such as low strength and insufficient hardness. Infiltrating copper can increase the density of iron-based parts to 7.5g/cm3

Improve Strength

In addition, infiltration process can penetrate copper into powder metal components in a very short time and diffuse to the surroundings to produce solid solution strengthening, thereby enhancing the strength of the part.

Enhance Thermal and Electrical Conductivity

Copper is a material with high thermal and electrical conductivity, so copper infiltration can effectively enhance the electrical and thermal conductivity of parts.

Fill Pores

Infiltrating copper into the pores of parts help improve the coating surface. This prevents the plating liquid from penetrating into the internal gaps of parts and causing corrosion.

Applications of Powder Metallurgy Infiltration Process

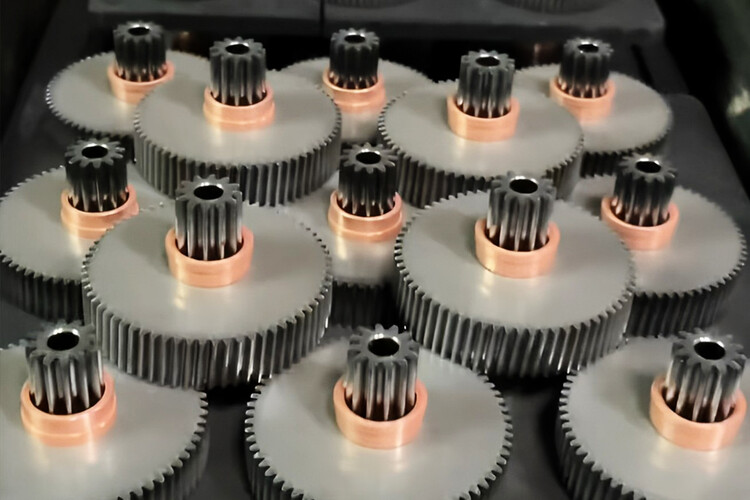

Power Tools

Copper infiltration is ideal for use in power tools, such as drive gear, driving gear, planetary gear and planet carrier. By filling the pores in the base metal, copper penetration makes power tools stronger and more durable.

It is contribute to conduct heat in power tools, preventing overheating and extending their lifespan.

Automobile industry

Copper infiltration in powder metallurgy increases the strength and hardness of components. Therefore, copper-infiltrated components are ideal for automotive components such as gears, clutch plates, sprockets, and synchronizer hubs.

Machinery Industry

Infiltrating copper improves the tensile strength of the material and enhances the durability and reliability of mechanical parts. In multi-component assemblies, copper-infiltrated parts have good sealing and bonding strength. This applies to various hydraulic pressure sealing systems, such as valves and pumps.

Impregnation vs. Infiltration

Both impregnation and infiltration in powder metallurgy introduce additives to fill part pores.

Infiltration fills the pores in components by introducing molten metal. It often occurs at high temperatures. The main purpose is to enhance the density and strength of parts.

Impregnation introduces non-metallic materials, such as oils and resins, to fill porous metal parts. Impregnation is usually carried out at room temperature, using high pressure to penetrate the material into the internal voids of the parts.

Oil impregnation boosts product lubrication and surface sealing, while resin infiltration aid to seals holes. Sealing is important for later surface treatments like:

- Galvanizing

- Nickel plating

- Chrome plating

- Dacromet

In our production, copper infiltration also encountered some problems. For instance, if the density of green parts is greater than 6.9g/cm3, it is difficult to execute the infiltration process.

This is because some of the gaps in the parts have been closed and are not connected to the outside. The molten metal cannot enter the internal gaps, which will cause metal residue.

For products with high strength requirements or significant height, we usually perform secondary Infiltration. After first infiltration process, turn the product over and place the copper piece for another infiltration.

FAQ

1. What is the Difference between Liquid Phase Sintering and Infiltration in Powder Metallurgy?

Liquid phase sintering introduces a liquid phase metal to the substrate. The liquid phase promotes the rearrangement and binding of solid particles, resulting in densification and enhanced properties.

Infiltration is when a metal with a lower melting point, such as copper, is brought to a molten state through high temperatures. And penetrate into the metal voids through capillary action.