Sandblasting is a surface finishing process that uses high-pressure abrasive media to clean and smooth material surfaces. The impact of the abrasives removes contaminants, rust, paint, or burrs, and modifies the surface texture.. Its origin dates back to the 19th century; used to clear rusted steel, prepare surfaces for painting, or etch designs into glass. However, it threatens the environment and its users, due to the noise and dust produced by the machines during operations.

According to the Business Research Insights, the sandblasting market size was rated at about USD 0.54 billion last year. It is, however, projected to have a CAGR of 5.9% every year till 2033 resulting in an estimated growth of approximately USD 0.9 billion.

Contents

What is Sandblasting?

Sandblasting is the process of cleaning, smoothing, or roughening a hard surface. It entails forcibly applying abrasive materials, like sand, against a surface at high speed. This is done with the use of compressed air or other similar systems. As mentioned earlier about the change in blasting media used for the process, modern abrasive blasting engages a variety of options. These include glass beads, aluminum oxide, plastic beads, and dry ice. Its applications cut across several important industries.

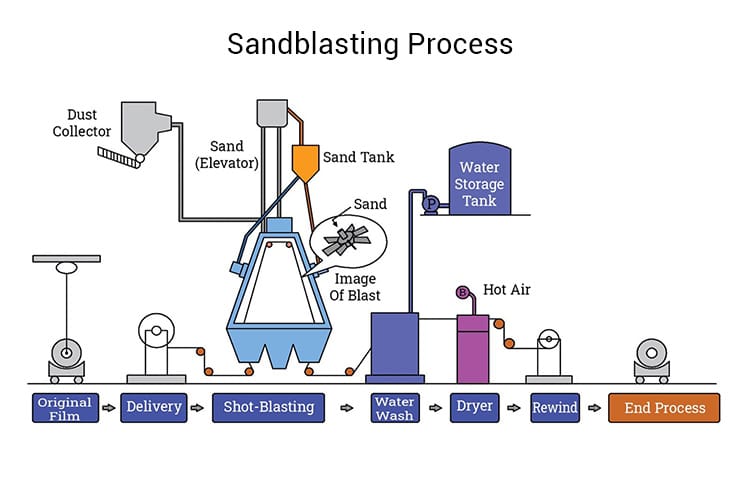

Sandblasting Process

The first step is to prepare the surface of the material to be blasted by covering the parts that shouldn’t be affected. Next, choose the appropriate abrasive media based on your desired goal and type of surface. The blast pot holds the abrasive media in the chamber, and channels the particles into the pop-up valve. The air intake is powered by the air compressor which pressurizes the media in the chamber. This comes out of the nozzle at high speeds to hit the surface with force.

Types of Sandblasting Techniques

There are various techniques used in modern sandblasting, each for specific applications:

Dry-Ice Blasting

A simple cleaning process that uses frozen CO₂ pellets as the blasting medium. It removes contaminants from surfaces without using abrasives, chemicals, steam, or high temperatures.

Vacuum Blasting

It is also known as dustless blasting because it extracts the dust produced during the process using a vacuum system. This technique is safe and cost-effective because the abrasive media can be reused, and it minimizes environmental contamination.

Micro-Abrasive Blasting

It propels a stream of fine abrasive particles, at lower pressures, against a hard surface for precision cleaning or cutting. This technique is applied in electronics and other delicate components.

Bead Blasting

It uses glass beads to create a smooth, satin finish on metal surfaces. This technique is widely used for cosmetics and cleaning stainless steel.

Wet vs. Dry Sandblasting

- Dry Sandblasting is commonly used in industrial applications. It needs protective equipment and active ventilation because it produces more dust as it is an aggressive process.

- Wet (Dustless) Sandblasting lessens the dust by combining water with abrasive media. This makes it more suitable for delicate surfaces, or environments with dust restrictions.

What is Sandblasting Used for?

Surface Preparation

Sand blasting Creates a rough surface for better adhesion of coatings, paints, or plating.

Deburring

Sandblasting smooths sharp edges, removes burrs, and eliminates flash on powder metallurgy parts, machined components, and castings.

Surface Cleaning

Abrasive blasting can be used to remove rust, scale, oil, old paint and contaminants prior to machining or coating.

Automotive Industry

Used for the removal of rust, dirt, and preparing surfaces for repairs or painting e.g cleaning of engine parts, or preparation of antique cars.

Sandblasting Equipment

Sandblasting equipment varies depending on the nature of the task. First, let’s talk about two important components of a sandblasting machine:

- Blasting Nozzle: This component controls the direction of the stream of abrasive particles. Ensure that the nozzle tip spins at a speed high enough to propel the material with force from the hose. The different types of nozzles include straight, tapered, diamond, fluted, and reinforced flutes. Each type is for specific duties depending on your goal and the type of surface. The desired nozzle pressure is usually around 100 PSI and you can determine the size to use by checking the volume your air compressor can supply per minute.

- Air Compressor: It provides the pressurized air used for propulsion. This is a very important component because it powers the entire process. The size of the compressor must be one big enough to pressurize the blast pot for the pop-up valve to be sealed. The higher the CFM (cubic feet per minute) rating of a compressor, the better the sandblasting process. Generally a CFM rating of 18 – 35 is needed, but about 50 – 100 CFM is better for industrial sandblasting processes.

The basic sandblasting systems include:

- Portable Blasting Systems: A mobile system typically used for dry abrasive blasting, and powered by diesel air. It is used to transfer blast media into the main blast line.

- Open Blasting Systems: As the name implies, the system is not a closed loop one, it is open and commonly used for blasting outdoor surfaces e.g buildings.

- Sandblasting Cabinet: An enclosed system used to house the blasting material. It is usually made up of a containment, blasting system, recycling system, and dust collection.

Sandblasting Media: Choosing the Right One

This is the material propelled against the hard surface, and it is of different types, used depending on the surface type, blasting goal, or media cost. The different types include Organic (e.g walnut shells), Meta (e.g aluminium oxide), glass beads, etc.

To select the right abrasive media, you should consider:

- Hardness of the material.

- The desired goal for the surface finish.

- Safety and environmental concerns.

For example:

- Glass beads are used for smoothing and polishing.

- Steel grit is mostly ideal for aggressive blasting e.g rust removal.

- Sodium bicarbonate is gentle enough for blasting delicate surfaces.

Impact on Substrates

It’s also vital to match media hardness with the type of substrate used:

- Soft surfaces (e.g., wood or plastic) need less aggressive abrasives.

- Hard surfaces (e.g., steel, stone) can accommodate more aggressive blasting.

Due to concerns about the health and safety of users and the environment, other blasting alternatives have been considered. The use of eco-friendly abrasive media helps reduce negative environmental impact. The adoption of robotic sandblasting systems mitigates the exposure of workers to health and occupational hazards. Additionally, the enclosed systems, like blast cabinets, help collect dust and recycle media, thereby minimizing waste and reducing costs

FAQ

1. What is the Difference between Sandblasting and Shot Blasting?

While both processes are good for surface preparations and cleaning using abrasive materials, they differ in the type of media used. Sandblasting uses fine media and compressed air, whereas shot blasting uses small amounts of metal called shot. Shot blasting is generally safer than sandblasting as it produces no dust residue, hence, no room for inhalation.

2. What are the Safety and Environmental Concerns for the Sandblasting Process?

- Inhalation risks: Fine particles like silica can lead to respiratory issues. Proper PPE, such as respirators and cover-all suits, is important for workers’ protection.

- Noise: High decibel levels could lead to hearing issues, hence, workers may require hearing protection.

- Waste Management: The abrasive residues produced during the sandblasting process must be handled according to environmental guidelines to prevent contamination

3. Can Sandblasting Damage Surfaces?

Yes, sandblasting can damage surfaces if not properly executed. Aggressive media or high pressure on soft materials can lead to negative effects like pitting, warping, or erosion. It is important you choose the right media and also test on small areas first to avoid damage