Oil pump gears are high-precision components of an oil pump, determining the effectiveness of an oil pump to deliver oil throughout the system. These gears work on the principle of positive displacement, and the rotation of these gears is responsible for the movement of fluid within the pump. The geometry of the gear teeth and the meshing accuracy collectively determine volumetric efficiency, pulsation levels, and durability of the oil pump.

Contents

How Oil Pump Gear Works?

Gear Meshing Action

Rotation of the drive gear forces the idler gear into counter-motion. This meshing action establishes the pumping pattern supporting the fluid movement.

Drawing Oil in

As soon as the gears’ teeth move apart and separate on the suction side, empty spaces open up, and the pressure in these spaces drops. This low-pressure zone pulls oil from the sump into the open spaces of the gear chamber.

Fluid Entrainment

Now the oil is confined between the gear flanks and the surrounding housing. It is carried around the outside of the gears toward the outlet.

Pressurized Delivery

On the outer side, the gears re-engage, and the open spaces shrink, causing the forcing the trapped oil toward the discharge port. In this way, the oil is expelled through the discharge port in a controlled, metered volume with every rotation.

Pressure Stabilization

In order to keep the downstream lubrication stable and to prevent overloading, a relief valve is included. If pressure rises too high, some oil is sent back to the inlet or sump to protect the system.

Types of Oil Pump Gears

External Gear Set

An external gear set consists of two externally cut gears that rotate in opposite directions when the teeth of the gears mesh. These gears rotate within a housing; one gear acts as a driving gear, and the other as an idler. The oil pump, which operates using these gears, is termed an external oil pump gear.

External oil pum gears are primarily consist on supr gears. These straightforward design gears are typically used in applications with lower speeds of about 600 rpm. Their simplicity makes them cost-effective and reliable.

Performance of External Oil Pump Gears

Oil pump gears with a higher number of teeth generally experience reduced leakage losses and deliver smoother, more consistent flow. These gears are capable of generating high operating pressures and are well suited for handling oils and other viscous fluids,

Internal Gear Set(Gerotor

An internal gear set, or gerotor, consists of two elements: a smaller inner gear (idler) and a larger outer gear (rotor) with internal teeth. The inner gear is shaft-driven and mounted slightly off-center within the outer rotor. As it rotates, this eccentric motion causes the gears to mesh and unmesh, creating expanding cavities on the inlet side and contracting cavities on the outlet side. These cavities draw in, transport, and discharge the oil, enabling continuous positive-displacement pumping

Handling Versatile Fluids

An internal gear within an oil pump can handle a wide range of fluids. For example, they can handle very viscous products like petroleum, while also transferring lighter fluids such as fuels or lubricating oils.

Operational Edge

The design of internal oil pump gears allows bi-directional operation, which means they can pump in either direction. That’s why they are useful for tasks like filling and emptying containers with equal efficiency.

Materials for Manufacturing Oil Pump Gears

Steel

Steel is used for oil pump gears, which require high strength, wear resistance, and durability. Heat-treated alloy steels provide long service life under high pressure and speed.

Cast Iron

Oil pump gears are manufactured using cast iron for its good machinability, thermal stability, and vibration damping. Such gears are suitable for moderate load applications at a lower cost whereas it is less commonly used in modern automotive oil pumps.

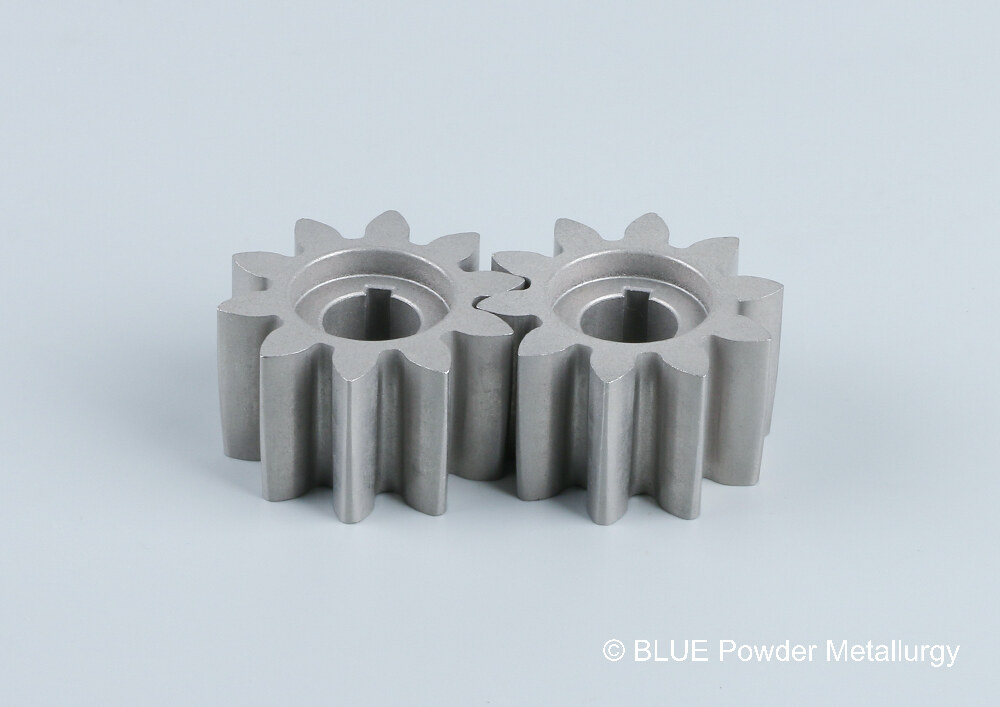

Powder Metallurgy Materials

Manufacturers apply powder metallurgy materials in mass production of complex gear shapes, gaining cost efficiency and consistent quality, while surface hardening further enhances wear and fatigue strength.

Applications of Oil Pump Gears

Automotive engines

Oil pump gears are used in engine lubrication to ensure oil is delivered from the oil pan/sump to bearings, camshafts, and other moving parts. These are also used in fuel oil transfer, especially in systems where the pump must resist wear and maintain flow when engine RPM varies.

Diesel Engine

In trucks, buses, and off-road machinery, oil pump gears handle continuous duty, often under high load and at variable temperatures. They maintain lubrication even under high viscosity oil conditions.

Hydraulic Systems

Oil pump gears also find their application in the hydraulic circuits of mobile and stationary machinery, such as excavators, agricultural tractors, lifts, and presses. Here, oil pump gears provide hydraulic power by generating pressure and flow for actuators.

Industrial Lubrication

In industrial equipment, including machinery, turbines, and gearboxes, oil pump gears circulate lubricant to reduce friction and remove heat. Their reliability ensures minimal downtime.

Powder Metallurgy Oil Pump Gear

Powder metallurgy oil pump gears are produced through a controlled press-and-sinter route. Iron-based powders, often alloyed with copper or nickel, are blended with lubricants to improve flow and compaction. The mixture is compacted in precision dies at high pressure to form a green gear with accurate tooth geometry. These compacts are then sintered in a continuous furnace under a protective atmosphere, where solid-state diffusion bonds the particles and develops the required strength.

Secondary operations further enhance performance: sizing improves dimensional accuracy, case hardening or surface densification increases wear resistance, and oil impregnation provides self-lubrication.

BLUE is a dedicated powder metallurgy manufacturer, providing a full range of standard oil pump gears and rotors. You can browse our oil pump gear shop for ready selections or download the complete product catalog. For specialized needs, we supply customized solutions designed to meet your project requirements.