ABS Sensor Ring

BLUE is a professional ABS sensor ring manufacturer offering over 500 standard powder metal rings for passenger cars, heavy trucks, and off-road vehicles. All standard abs rings require no tooling costs and support stable mass production.

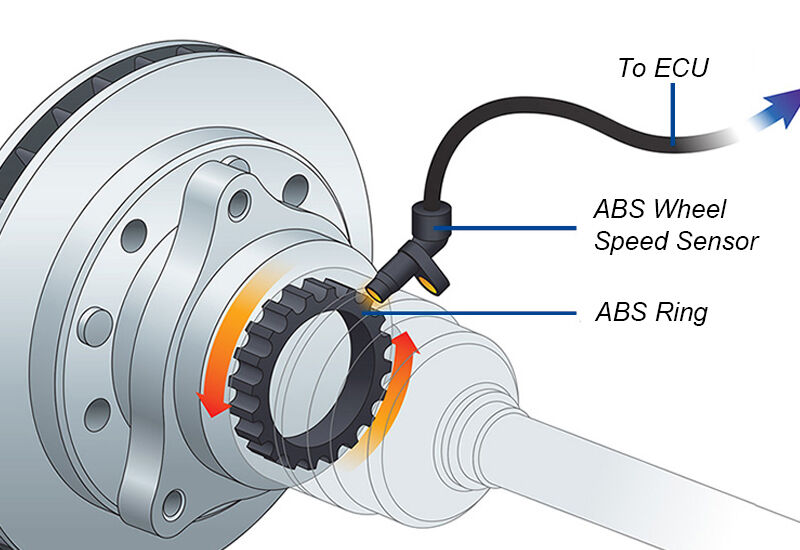

An ABS ring (also called a sensor ring or tone ring) is a toothed metal or magnetic ring mounted on a vehicle’s wheel hub, axle, or brake rotor. As it rotates, the teeth or slots pass by the ABS sensor, creating a changing magnetic field. The sensor converts this change into an electrical signal, which the ABS control unit uses to calculate wheel speed. This information allows the anti-lock braking system to detect if a wheel is locking and adjust brake pressure to maintain traction and steering control.

Function of ABS Ring

Collaboration with ABS Sensors

The ABS ring works in combination with ABS sensors to monitor the speed of each tire to ensure proper rolling of tires. These rings have bumps or teeth on them and are placed near the brakes.

Real-Time Data Transmission

The ABS sensor reads the ring’s movement and sends corresponding signals to the control unit.

Response to Irregularities

If any irregularity in the speed of all four tires is detected, it releases and applies pressure on the brakes in a specific manner to stop the tire from locking up. This helps maintain traction, control, and overall vehicle stability by decreasing stopping distance.

Types of ABS Rings

Here are the two main types of ABS rings:

Toothed ABS Rings

These rings are also known as reluctant ABS rings. These are made up of metal with evenly spaced teeth. Toothed abs rings are usually mounted on the driver shaft or axle. Whenever a bump passes across the sensor it creates a pulse or frequency signal.The higher the pulse rate, the higher the speed of the wheel.

Magnetic ABS Rings

Unlike toothed ABS rings, these rings come with a flexible circular band embedded with alternating north and south magnetic poles. These poles are often described as magnetic barcodes. Magnetic ABS rings work in combination with active sensors mounted on wheel hubs, bearings, or drive shafts.

Signal Generation Mechanism

Whenever the magnetic pole passes in front of the sensor, it alters the magnetic field. As a result, an electrical signal based on pole frequency is generated, which is directly tied to wheel speed. Magnetic AB rings have replaced toothed rings in modern vehicles.

Reluctor Vs Magnetic ABS Rings

| Features | Reluctor ABS Ring | Magnetic ABS Ring |

|---|---|---|

| Accuracy | Less consistent due to mechanical nature | More consistent and predictable signal |

| Durability | Susceptible to rust, cracking, and impact damage | More resistant to corrosion, cracks, and mechanical damage |

| Size and Design Flexibility | Generally larger and more rigid | Can be smaller and more compact |

| Susceptibility to Debris | Teeth can collect dirt and mud, affecting performance | Smoother surface is less prone to debris accumulation |

Placement of ABS Rings

Placement of the ABS ring depends on the wheel type and vehicle model. Here is the most common way in which Abs rings are placed:

Placement of ABS Rings in Front Axle

In the front axle, the ring is mounted on the wheel hub. This wheel hub is usually situated between the brake disc and a protective steel plate. This position of the abs ring shields them from environmental elements, which minimizes the chances of corrosion.

Placement of ABS Ring in Rear Axle

ABS tone rings in the rear axle are commonly located on the rear driveshafts, just before they connect to the wheel hubs. This placement makes them more exposed to environmental factors; as a result, they are at higher risk of corrosion and damage.

Common Symptoms of a Faulty ABS Ring

ABS Light Illuminates

ABS rings generate variable frequency signals that are detected by the sensor and finally sent to the ABS electronic control unit (ECU). If some sort of problem arises in the ABS ring system, the ECU does not receive accurate wheel speed information. As a result, the ABS light on the dashboard illuminates, indicating the problem with the ABS system.

Complete ABS Disengagement During Hard Braking

We know that ABS rings maintain the vehicle balance and save it from skidding when you apply hard brakes. If an ABS ring fails, the ABS system may disable anti-lock function for that wheel, increasing the risk of skidding during hard braking.

Maintenance of ABS Rings

Here are some maintenance tips for your ABS rings:

Clean Regularly

ABS rings might get dirt or debris on them with the passage of time, so to make them function properly, it is essential to clean them on a regular basis.

Inspect the Corrosion

You should continuously check for corrosion on ABS rings; if you find any corrosion, it is preferable to remove this, but if the damage is not reversible, you may need to change the ABS rings.

Inspecting ABS Light

You should keep a check on the ABS light present on your dashboard. This light lights up only when there is some problem with your ABS sensor or ring. This might indicate that your rings need a professional checkup.

Causes of ABS Ring Failures

Corrosion and Dirt

ABS sensors read the signals of frequency generated by the rings. If the rings are dirty or corroded, they will deliver inaccurate pulses to the sensor. This could be a possible cause of faulty ABS rings.

Structural Damage

One of the major causes of faulty ABS rings is the structural damage. If the rings are damaged or distorted, they wouldn’t generate a proper signal for the sensor, and the ABS system will not properly cause a faulty ABS ring.

Powder Metallurgy ABS Sensor Ring

Powder metallurgy is a widely used manufacturing process for producing ABS rings due to its cost-effectiveness in high-volume production, tight dimensional control, and minimal need for secondary machining. Sintered ABS rings are manufactured by mixing F-0000 powder, then compacting and sintering to form the final product.

FAQ

How to Replace ABS Rings?

- To replace the ABS ring, first of all, the driveshaft is removed from the vehicle.

- After removing the shaft, the old ABS ring is detached. It usually requires low force.

- Now thoroughly clean the area where the new ring will be seated. For this, you can use a wire brush or file to remove rust flakes.

- Now try to install a new ring; if it doesn’t slide easily, remove it and clean the shaft surface again.

- Gently tap the new ring into position. You can use the old ring as a buffer to protect the new one during installation.

- When the ring is properly seated, you need to reinstall the driveshaft following your vehicle’s specifications.

- Finally, give the ABS sensor a quick clean to ensure accurate signal detection.

- Now it’s all done, you can take the car for a short drive. The ABS warning light should stay off.