Water pump pulley is an important part of your engine’s cooling system. It connects the drive belt to the pump and transfers power to the impeller. With this power, the pump circulates coolant through the block and radiator to remove heat. This process keeps your engine at the right temperature and prevents damage from overheating.

In some designs, the water pum pulley is bolted to the pump hub, while in others it is built as part of the pump. In every case, the pulley is the link that keeps your belt system and cooling system working together.

Contents

Function of Water Pump Pulley

When your engine runs, the crankshaft turns the belt. The belt rotates the pulley, and the pulley drives the pump shaft. As the shaft turns, the impeller pulls coolant from the radiator, pushes it through the engine, and returns it to the radiator. The speed of the pulley controls coolant flow under different loads, so your engine always gets the cooling it needs.

Types of Water Pump Pulleys

Serpentine Belt Pulley

A serpentine belt water pump pulley is usually installed in modern vehicles, as it has a long continuous belt to power several components at once, such as the water pump, alternator, and power steering pump. These pulleys offer a more smoother operation and higher durability; that’s why they have become a preferred choice in contemporary engine systems. Automakers favour this design since it requires only one belt for multiple accessories, which makes the engine bay less crowded and lowers routine maintenance.

V-Belt Pulley

This pulley is designed to work with a belt with a V-shaped cross-section. In older vehicles, the water pump is often driven by a V-belt pulley. Unlike the serpentine setup, these belts are shorter and usually connect to fewer parts at a time. The grooved shape of the pulley allows the belt to grip firmly to ensure steady power transfer. While considered traditional, V-belt pulleys are considered reliable in classic cars and certain industrial applications.

What are Water Pump Pulleys Made of?

Aluminum

Aluminum water pump pulleys are common in modern vehicles because they are lightweight and reduce rotational mass. This improves engine response and efficiency while still providing reliable power transmission.

Cast Iron

Cast iron were standard in older vehicles due to their ability to withstand high mechanical stress. Today, they have largely been replaced by stamped steel or aluminum alloys, which offer similar strength with lower weight.

Steel

Steel water pump pulleys are widely used for their strength and durability. Stamped sheet steel allows cost-effective manufacturing with the mechanical properties needed for long service life.

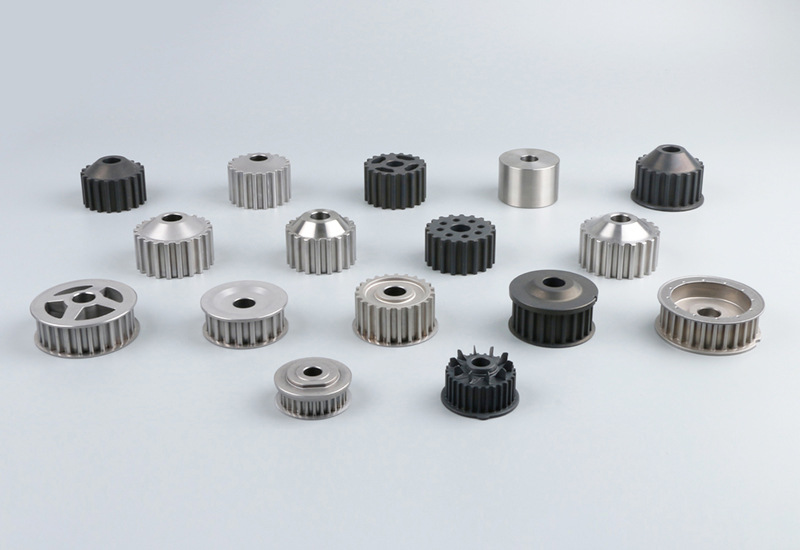

Powder Metal

Powder metal materials are widely used in producing modern water pump pulleys. The process allows near-net-shape parts with high dimensional accuracy and consistent strength.

Maintenance of Water Pump Pulley

Routine Inspections

Maintenance of a water pump pulley is important for a smoother operation of the engine. For this purpose, you should do a routine inspection of the pulleys. A healthy pulley should rotate smoothly without wobbling or resistance. During servicing, the pulley and its belt should be examined for signs of wear such as cracks, glazing, or uneven surfaces. You should also pay attention to small changes like looseness or rough movement; they can help detect problems with the pulley or its bearings before they worsen.

Alignment Checks

Pulleys must stay in line with one another for a belt-driven system to work efficiently. If the water pump pulley sits out of alignment with the crankshaft or accessory pulleys, the belt can slip, fray, or wear unevenly.

Protection Against Damage

External factors can also shorten pulley life, such as road debris, accidental impacts during maintenance, or corrosion from moisture, which can all compromise performance. Installing protective covers where available and handling the pulley carefully during belt replacement helps preserve its integrity.

What are Water Pump Pulley Failure Symptoms?

Unusual Engine Noises

One of the indicators of a falling pulley is the high-pitched squeals or grinding noises from the front of the engine. These sounds are usually linked to worn or damaged bearings inside the pump.

Pulley Wobbling or Looseness

When the mounting bolts loosen, the pulley wobbles while the engine is running. Such a condition can indicate that the pulley itself has cracked or the water pump bearing has started to fail.

Belt Slippage and Reduced Coolant Flow

If the pulley slips, the belt cannot turn the water pump at the correct speed. This reduces coolant circulation, especially at higher engine loads, and may quickly lead to overheating. In such conditions, the belt squeal or visible signs of glazing on the belt surface are common indicators.

Coolant Leaks and Visible Damage

Puddles under the car or dried residue near the pulley are strong signs of damage. Ignoring these leaks risks engine overheating and severe mechanical failure.

Powder Metallurgy Water Pump Pulley

A powder metallurgy water pump pulley is made by pressing metal powder into shape and heating it in a furnace until the particles bond. After sintering, the pulley can be sized or given a surface treatment. This method uses less material, lowers cost, and makes accurate parts with stable quality. Sintered water pump pulley is strong, wear resistant, and provides consistent quality with good durability, well suited for large-scale automotive production.

BLUE is a professional powder metallurgy manufacturer in China. We supply a wide range of standard sintered water pump pulleys with no mold fees. Customers can easily select the right parts from our standard shop or download the product list. Custom solutions are also available to match specific project needs.

FAQ

How Long does a Water Pump Pulley Last?

Most pulleys last as long as the water pump itself, often between 100,000 miles to 150,000 miles, though wear depends on belt tension and driving conditions.

Can a Bad Pulley Cause Engine Overheating?

Yes. If the pulley slips or fails, the pump cannot circulate coolant effectively, which quickly raises engine temperature.

Can I Drive with a Bad Water Pump Pulley?

It’s risky; while the car may still run, a failing pulley can cause belt loss or overheating, leading to severe engine damage.